Pneumatic main cut-off change-over valve

A technology for switching valves and cylinders, applied in high-pressure air circuit breakers, valve details, multi-way valves, etc., can solve the problems of complex overall structure and poor reliability, and achieve the effect of simplicity, compactness, high reliability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The preferred embodiment of the pneumatic main break switching valve of the present invention is:

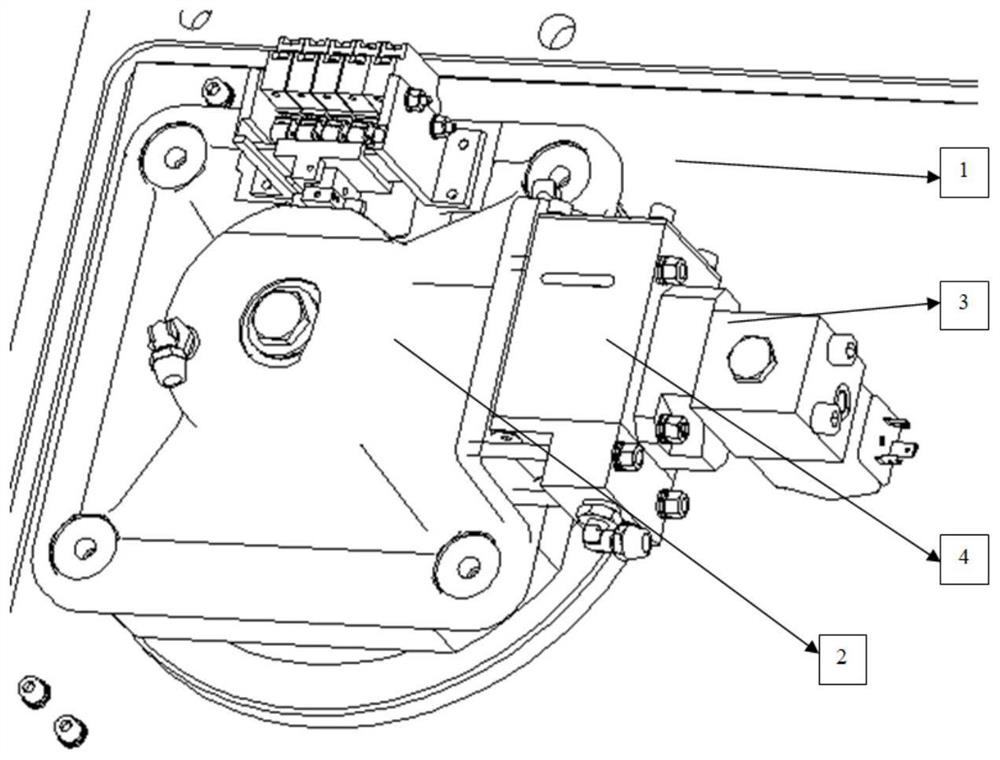

[0024] The vacuum circuit breaker includes a base 1, a cylinder 2, and a solenoid valve 3. The cylinder 2 is installed on the base 1, and a switch valve 4 is installed on the cylinder 2. The solenoid valve 3 Installed on the switching valve 4;

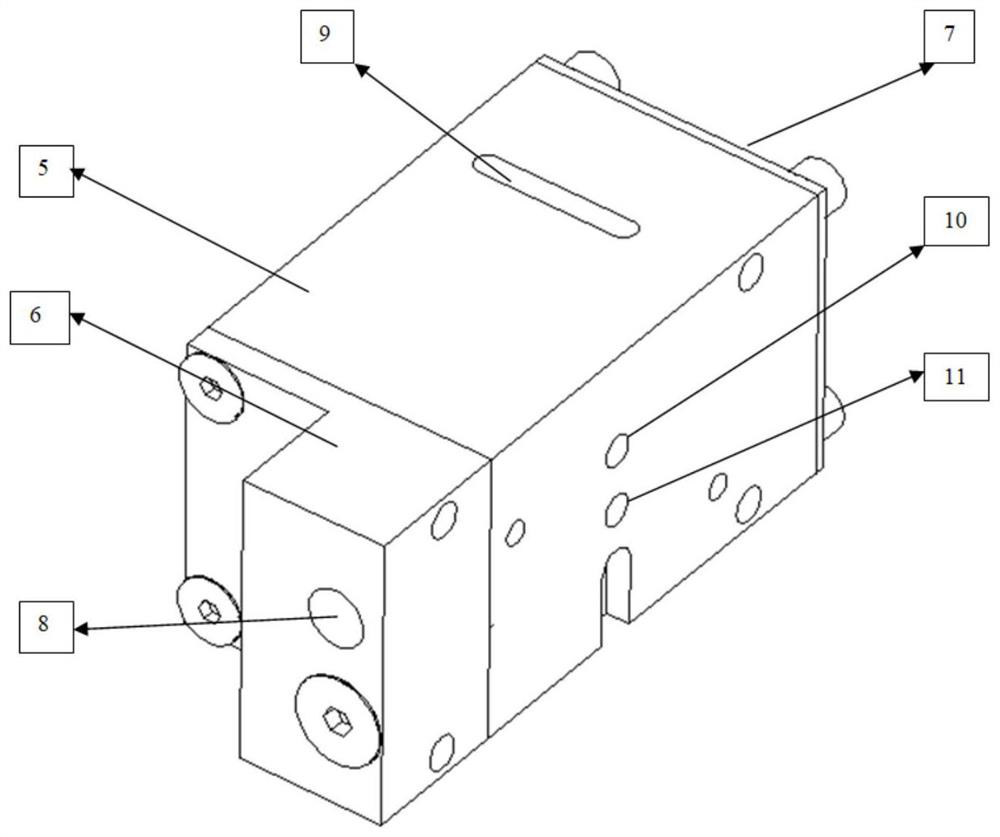

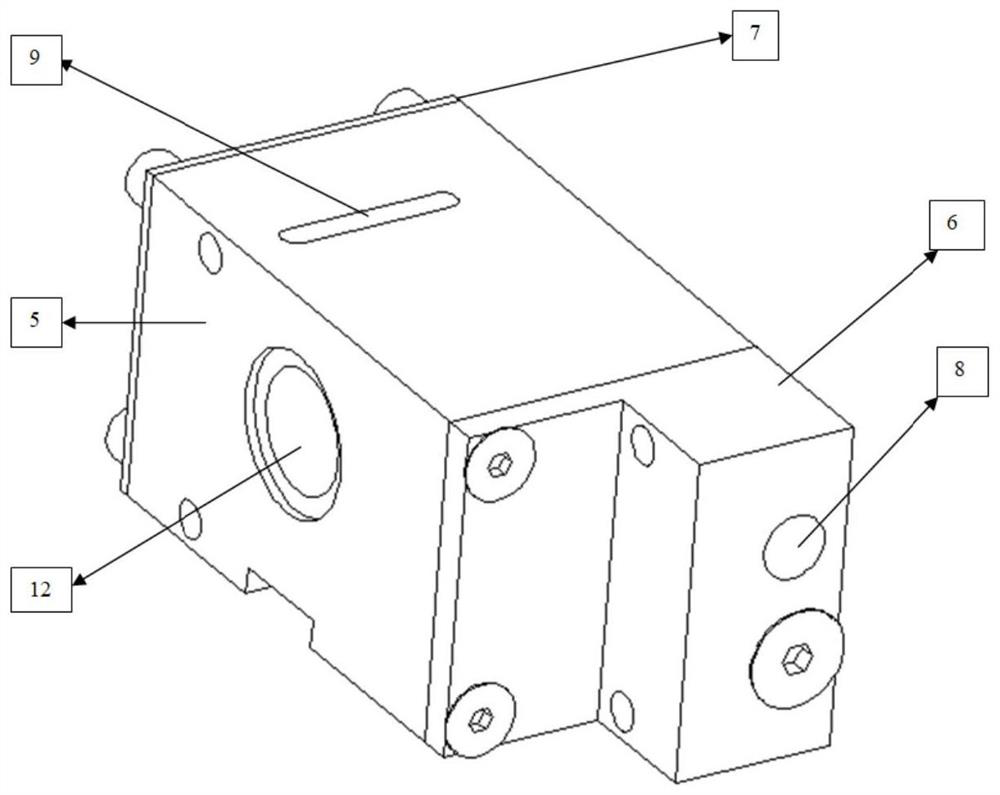

[0025] The external structure of the switching valve 4 includes a switching valve body 5, a top plate 6 and a bottom plate 7, the top plate 6 is provided with a total air intake hole 8, and the side of the switching valve body 5 is provided with an exhaust hole 9, The side of the switching valve body 5 close to the solenoid valve 3 is provided with a solenoid valve air inlet 10 and a solenoid valve gas outlet 11, and the side of the switching valve body 5 close to the cylinder 2 is provided with a cylinder inlet. Air port 12;

[0026] The internal structure of the switching valve 4 includes a poppet valve 13, a valve stem 14, a ...

specific Embodiment

[0038] The assembly structure of the conversion valve 4 in the vacuum circuit breaker is as follows: figure 1 As shown, it includes: base 1, cylinder 2, solenoid valve 3, switch valve 4, cylinder 2 is installed on base 1, switch valve 4 is installed on cylinder 2, solenoid valve 3 is installed on switch valve 4.

[0039] The external design structure of the conversion valve 4 is as follows: figure 2 and image 3 Shown: including switch valve body 5, top plate 6, bottom plate 7, total air intake hole 8, exhaust hole 9, solenoid valve air inlet 10, solenoid valve air outlet 11, cylinder air inlet 12, the changeover valve 4 consists of The switch valve body 5, the top plate 6 and the bottom plate 7 are composed, the total air intake hole 8 is the air intake hole on the top plate 6, the exhaust hole 9 is the exhaust hole on the switch valve body 5, the solenoid valve air inlet 10 and The solenoid valve air outlet 11 is the air inlet and the air outlet connected with the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com