Metal-based flexible frame quartz differential resonant pressure sensor

A pressure sensor, flexible-based technology, applied in the measurement of fluid pressure, measurement of force by measuring the frequency change of stressed vibrating elements, instruments, etc., can solve thermal mismatch, interference pressure sensor performance, alignment accuracy and connection Intensity affects the overall accuracy and reliability of the sensor, etc., to achieve the effect of suppressing temperature drift and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

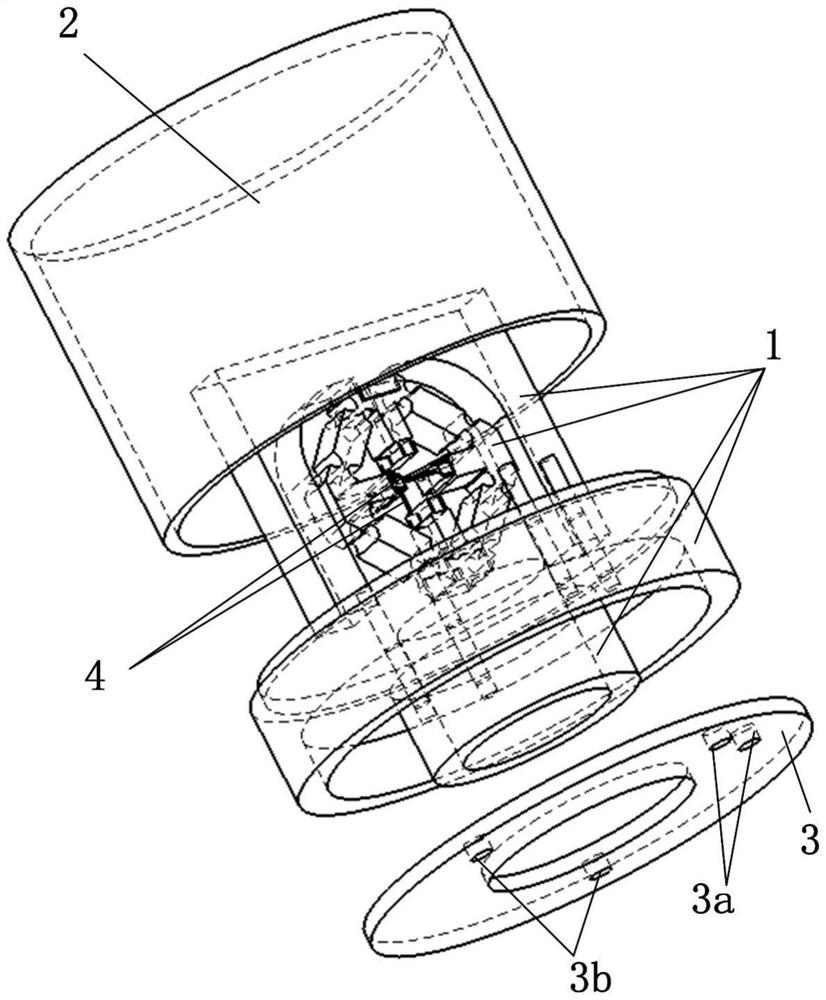

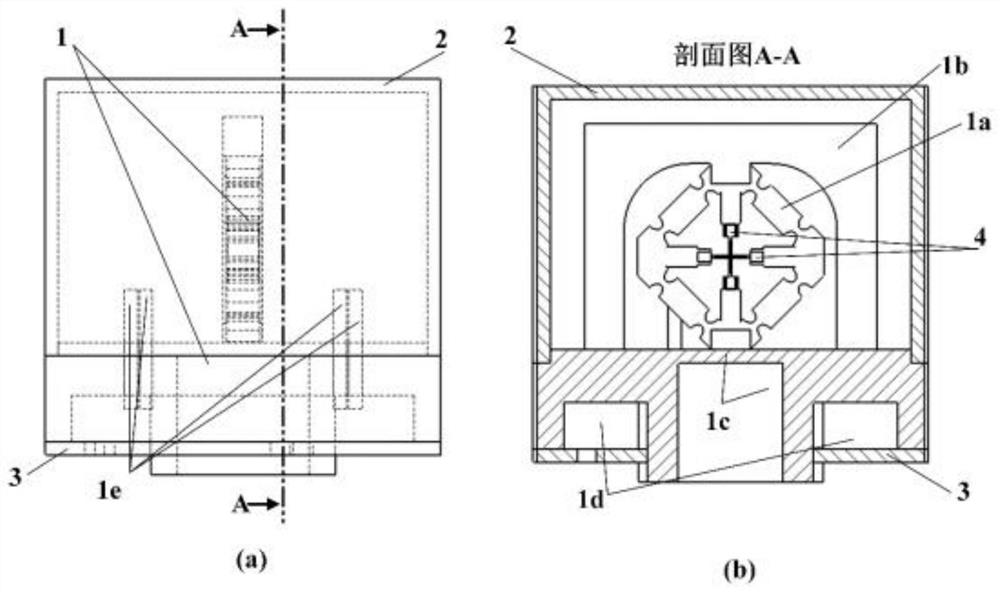

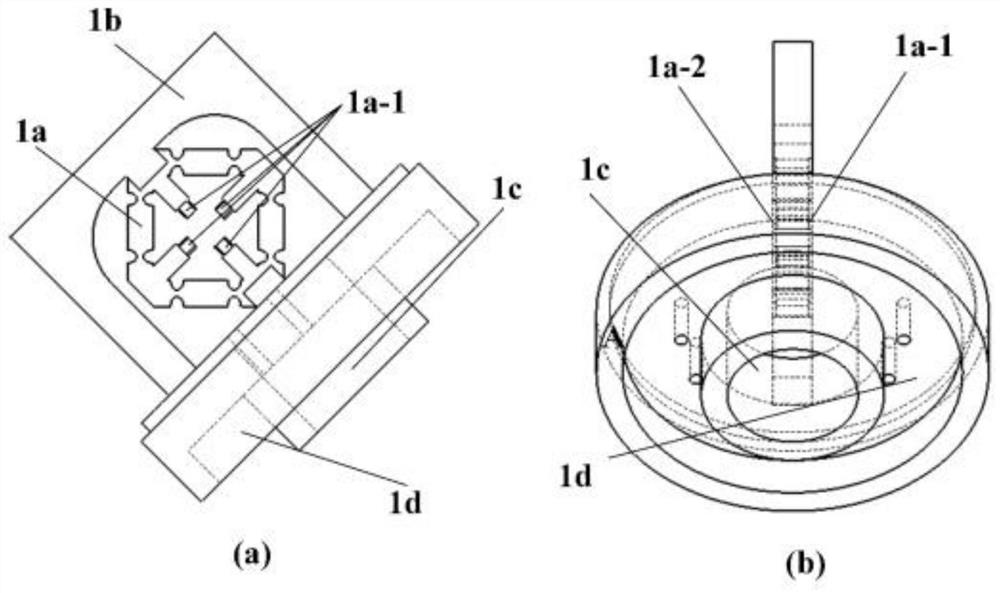

[0019] refer to figure 1 , figure 2 and image 3 , a metal-based flexible frame quartz differential resonant pressure sensor, including an integrated metal pressure differential conversion element 1, the integrated metal pressure differential conversion element 1 is connected with two quartz double-ended fixed support tuning forks 4, the integrated The upper side of the metal pressure differential conversion element 1 and the outer sides of the two quartz double-ended fixed support tuning forks 4 are connected with an upper cap 2 to form a vacuum seal to ensure the vacuum packaging effect of the resonance chamber; the lower side of the integrated metal pressure differential conversion element 1 A lower cover plate 3 is connected, and the lower cover plate 3 seals the PCB installation chamber 1d to complete ordinary hermetic packaging;

[0020] The integrated meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com