A method of deep loosening and fertilizing seedling belt rotary tillage precision seeding

A precision seeding and deep loosening technology, applied in planting methods, fertilizers and sowing equipment, agricultural machinery and implements, etc., can solve the problems affecting the seed emergence rate, corn growth, and the large difference in seed sowing depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

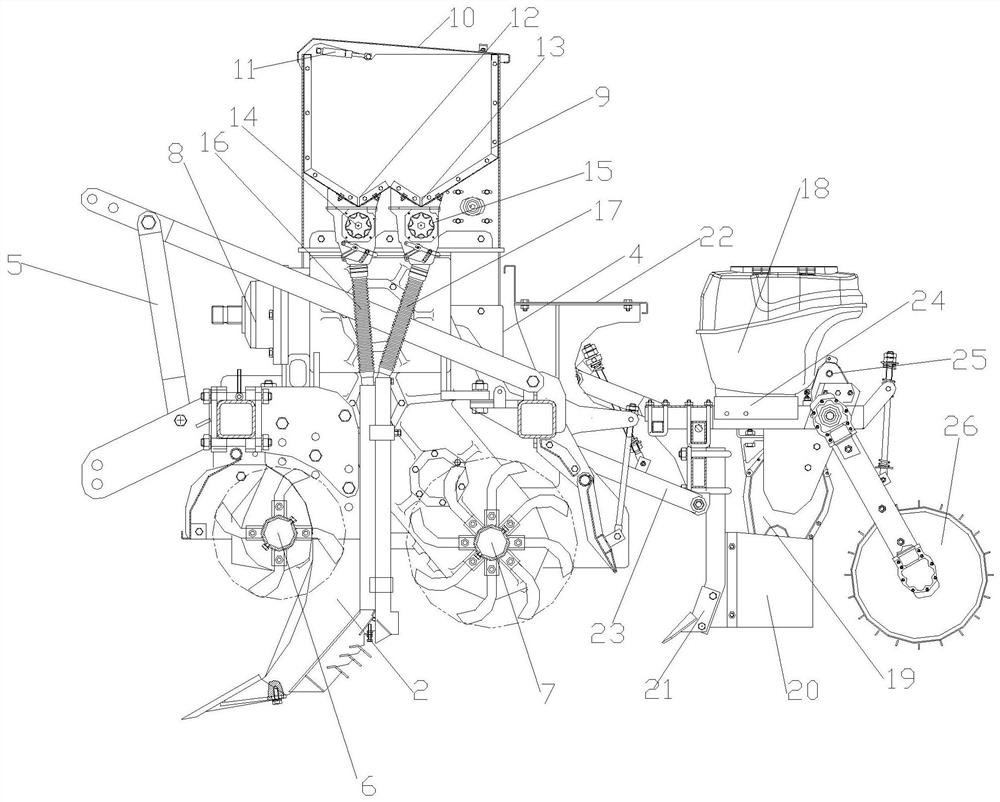

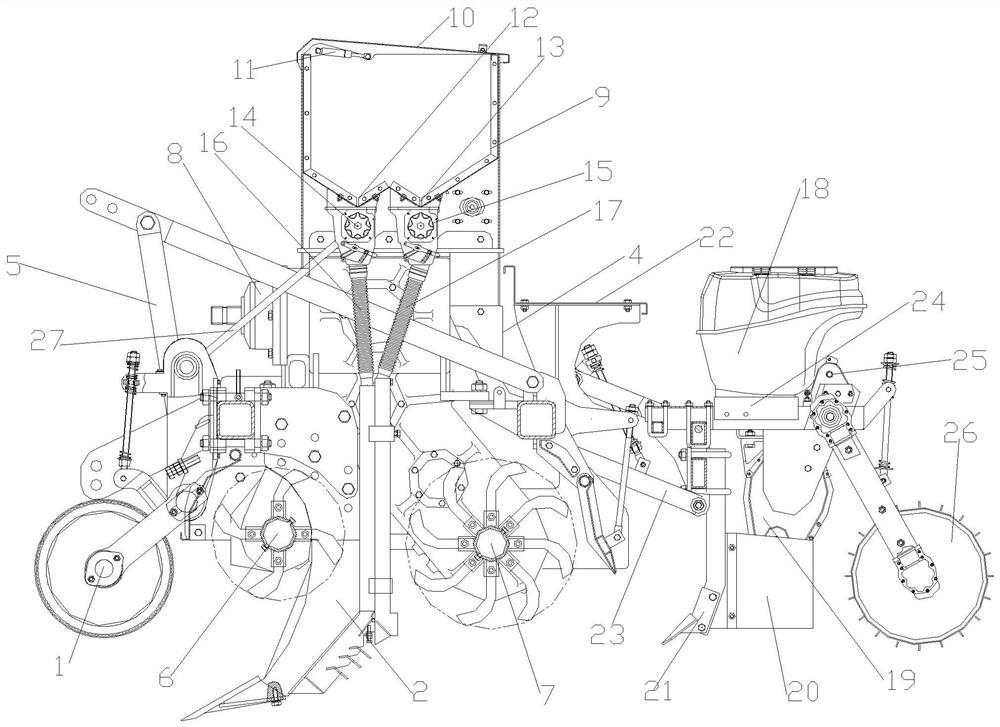

[0076] Such as figure 1 , Figure 5-Figure 8 Shown, a kind of deep loosening and fertilizing seedling belt rotary tillage precision seeding method of the present invention, utilizes deep loosening and fertilizing seedling belt rotary tillage precision seeding machine to carry out the deep loosening and fertilizing seedling belt rotary tillage precision seeding of deep-rooted crops, so The subsoiling and fertilizing seedling belt rotary tillage precision seeder includes a frame 4, a double output shaft gearbox 8 that is arranged on the frame 4 and connected with the output shaft of the tractor, and a seeder and a transmission that are connected at the rear end of the frame 4. Shovel front stalk remover 6, subsoiling multi-layer fertilization shovel assembly 2 and seed bed rotary tiller 7 are installed in sequence on the lower side of frame 4, and the front shovel straw remover 6 and seed bed rotary tiller 7 are all connected with each other. Double output shaft gearbox 8 trans...

Embodiment 2

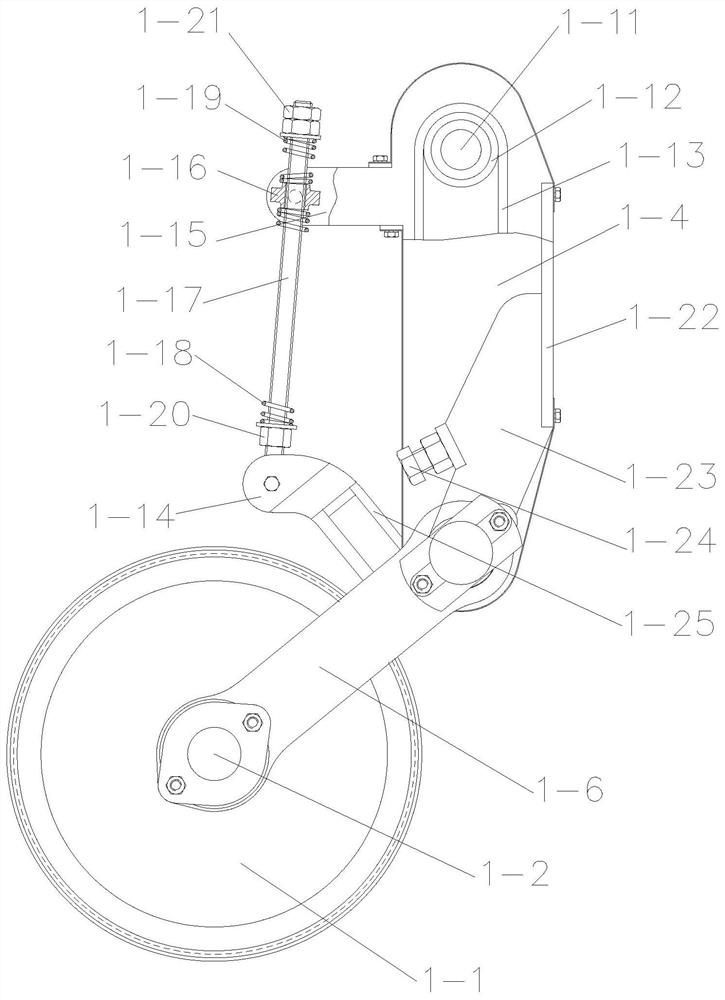

[0104] Such as Figure 2 to Figure 4As shown, the difference between this embodiment and the embodiment is that the front side of the frame 4 is equipped with a profiling depth-limiting transmission pressing wheel 1, and the profiling depth-limiting transmission pressing wheel 1 includes a The fixed bracket 1-4, the pressing wheel mechanism connected with the fixed bracket 1-4 and the transmission mechanism connected with the described pressing wheel mechanism, and the utility model arranged between the fixed bracket 1-4 and the described pressing wheel mechanism For the depth-limiting mechanism that limits the tillage depth, the crushing wheel mechanism includes a crushing wheel bracket rotatably mounted on the fixed bracket 1-4, a crushing wheel shaft 1-2 mounted on the crushing wheel bracket, and a crushing wheel shaft 1-2 fixedly mounted on the The pressing wheel 1-1 on the pressing wheel shaft 1-2, the transmission mechanism includes a transmission shaft 1-3 installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com