Preparation method of quinoa composite cereal solid beverage

A compound grain and solid beverage technology, which is applied in food science, functions and applications of food ingredients, etc., can solve the problems of affecting the taste, simple ingredients, large particles, etc., so as to avoid the chance of disease, avoid the decline of resistance, and facilitate Carrying the effect of eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]The present invention provides a method of preparing a buffer compound grain solid beverage, aiming to solve the particles, affect the taste, and the ingredients are simple, can only be used for fullness, can not provide a rich element in the case of small intake problem.

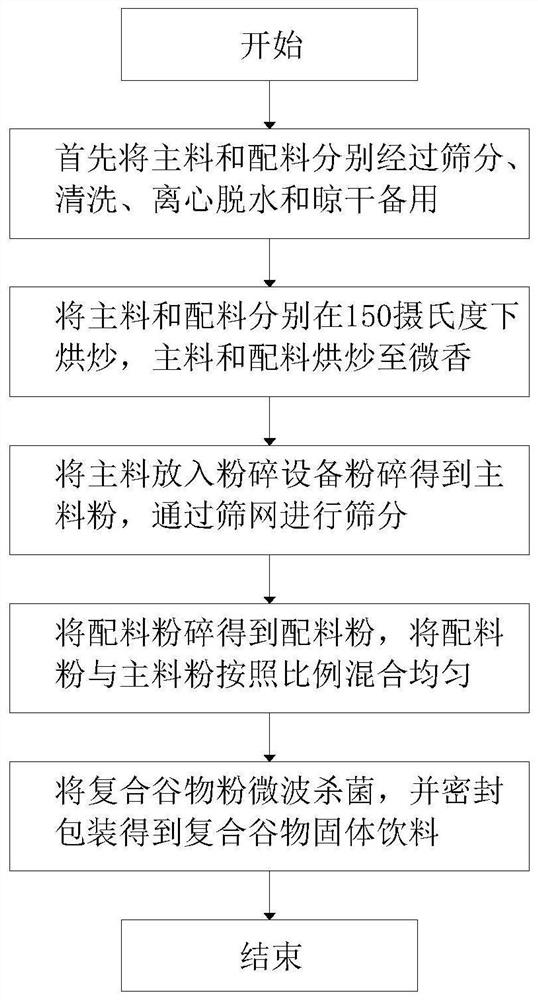

[0027]Such asfigure 1 As shown, a method of preparing a buffer compound grain solid beverage provided by the embodiment of the present invention, including material and ingredients.

[0028]In the technical solution of the present invention, by adopting the above technical solution, a large amount of nutrients in the ingredients can be mixed with the material, making the prepared compound cereal solid beverage containing a large amount and rich trace elements, not only having a full of fullness Function, and also provide a variety of trace elements needed to avoid the problem in the process of lacking trace elements in the process of long-term delivery, which can be presented by the preparation method of the abov...

Embodiment 1

[0029]Example 1: First, the main material and ingredients are selected, and the material includes the following weight parts: 20-25 bucka, 6-8 xylitol, 10-15 oatmeal, 5-8 parts of glutinous rice, corn 10-15 copies, 9-10, 3-6 almonds, 3-6 black beans, 8-12 black sesame, 10-15 large wheat, ingredients include the following weights: Lai 菔0.5-1 copies, 0.5-1 in the decido, 0.5-1 flanges, 0.5-1 licorice, 0.5-1 ginger, 0.5-1 serializes, 0.5-1 grape seeds 0.5 -1, 1-2 oza, 2-3 protein powder, 1-2 starch, 1-3 servants, 1-3 serial plants, 1-3 copper powder, fresh milk 1-3 parts, 1-3 mils, 1-3 brown rice, 1-2 of Bayern, 1 cashew noodle, 1-2 raisins, 1-2 of figs, 1,200 fungus, Yam 1-2, 2-3 苓, 2-3 lotus seeds, 2-3 red dates, 2-3 red beans, 2-3 white lentils, 1-3 walnuts, 1-3 parts, Lily 1-3 parts, 1-3 枸杞, 1-3 longen, 1-3 roses, sieving, dehydration, fried, pulverized, mixed, microwave bactericidal and package, can be produced by composite cereals solid beverages.

[0030]DETAILED DESCRIPTION OF THE...

Embodiment 2

[0037]Step 1: Firstly, the material and ingredients are screened by the screening device, respectively, respectively, and the screening of the material and the ingredients are first placed in the cleaning equipment, respectively, and dehydrated by centrifugal equipment;

[0038]Step 2: The main material and ingredients after dehydration will be baked for 20-60 minutes, and the material and ingredients are stirred up to the micro-fragrance;

[0039]Step 3: Put the baked material into the pulverized device to get the main powder, and sieve the screen of 140-160 mesh, so that the main material of the crush is smaller than the number of screens.

[0040]Step 4: Put the ingredients into the pulverized equipment to obtain the batch powder, and the number of points is the same as the main powder, and the blend powder and the main powder are mixed in proportion 5: 5, resulting in composite cereal powder;

[0041]Step 5: Put the composite cereal powder by microwave, and the sterilization of composite gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap