Freeze-dried ice cream and preparation method thereof

An ice cream and freeze-drying technology, applied in frozen sweets, cocoa, food science, etc., can solve the problems of not being suitable for people with poor stomachs, not being able to store for a long time, and being difficult to provide to consumers, so as to expand the suitable consumption time and convenience The effect of eating, carrying and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

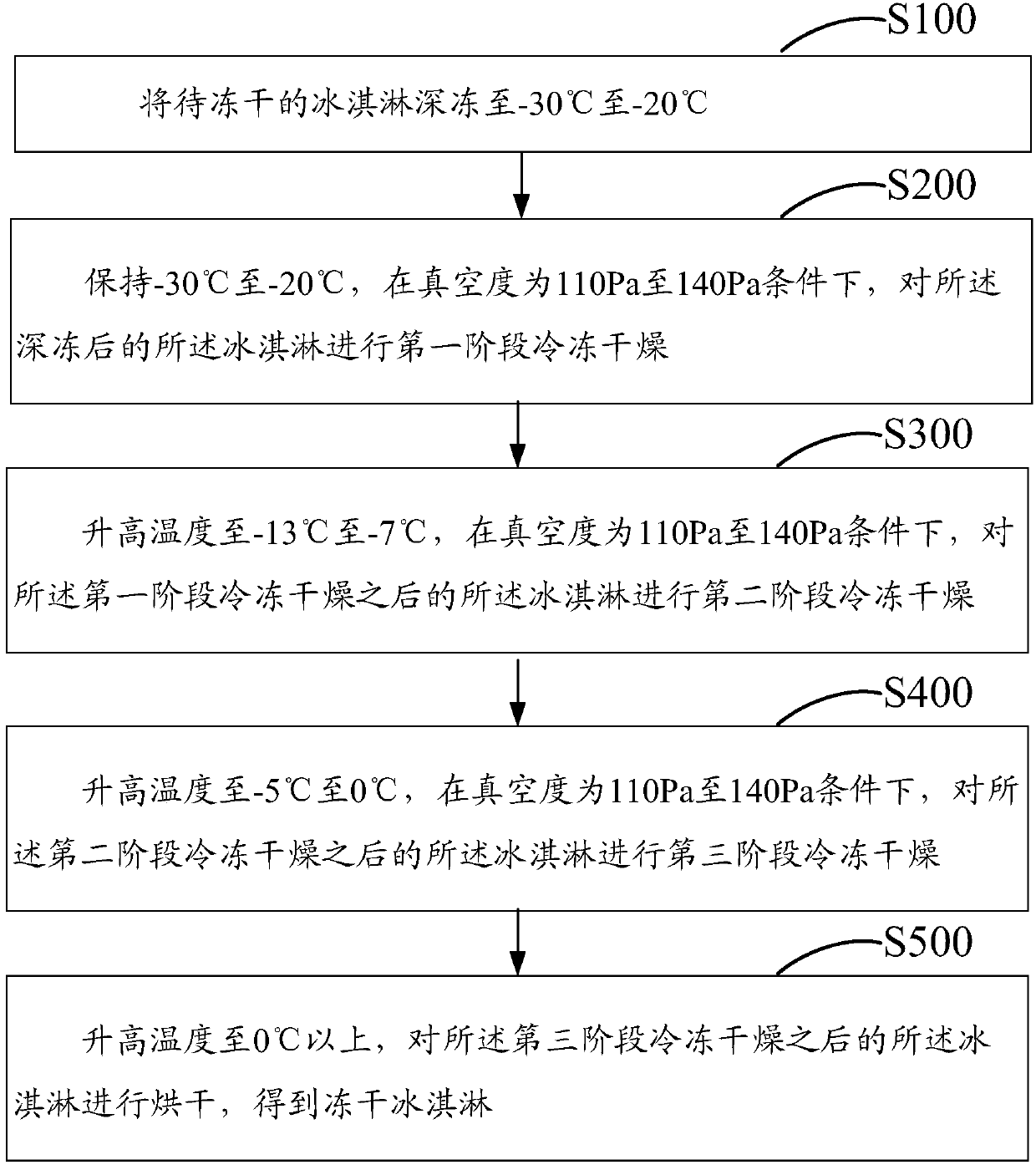

[0025] The invention provides a kind of preparation method of freeze-dried ice cream, comprising:

[0026] S100, deep freezing the ice cream to be freeze-dried to -30°C to -20°C;

[0027] S200, keeping the temperature at -30°C to -20°C, and under the condition of vacuum degree of 110Pa to 140Pa, conduct the first stage of freeze-drying on the deep-frozen ice cream;

[0028] S300, raise the temperature to -13°C to -7°C, and perform the second stage freeze-drying on the ice cream after the first stage freeze-drying under the condition of vacuum degree of 110Pa to 140Pa;

[0029] S400, raising the temperature to -5°C to 0°C, and performing a third-stage freeze-drying on the ice cream after the second-stage freeze-drying under the condition of a vacuum degree of 110Pa to 140Pa; and

[0030] S500, continue to raise the temperature to above 0° C., and dry the ice cream after the freeze-drying in the third stage to obtain freeze-dried ice cream.

Embodiment A

[0059] The preparation of the ice cream to be freeze-dried of embodiment A

[0060] The materials for preparing ice cream to be freeze-dried include: 1000g of whole milk powder, 250g of butter, 500g of whole egg, 500g of white sugar, 1650g of water, compound emulsification stabilizer: 16g of gelatin, 8g of konjac gum, and 8g of monoglyceride.

[0061] First of all, the mixing and batching of materials is carried out. Dissolve milk powder in warm water at 40°C to 50°C to form a milk powder solution; melt the cream at room temperature; mix the melted cream and milk powder solution and heat to boil; mix whole eggs and white sugar and whip at high speed; Dissolve the emulsification stabilizer and white sugar in a ratio of 1:5 in hot water at 50°C, and beat at high speed; finally, add all the materials into the mixing tank, gradually heat up to 70°C, add water to the weight required by the formula, and stir evenly ;

[0062] Secondly, first use a colloid mill to homogenize the un...

Embodiment 1

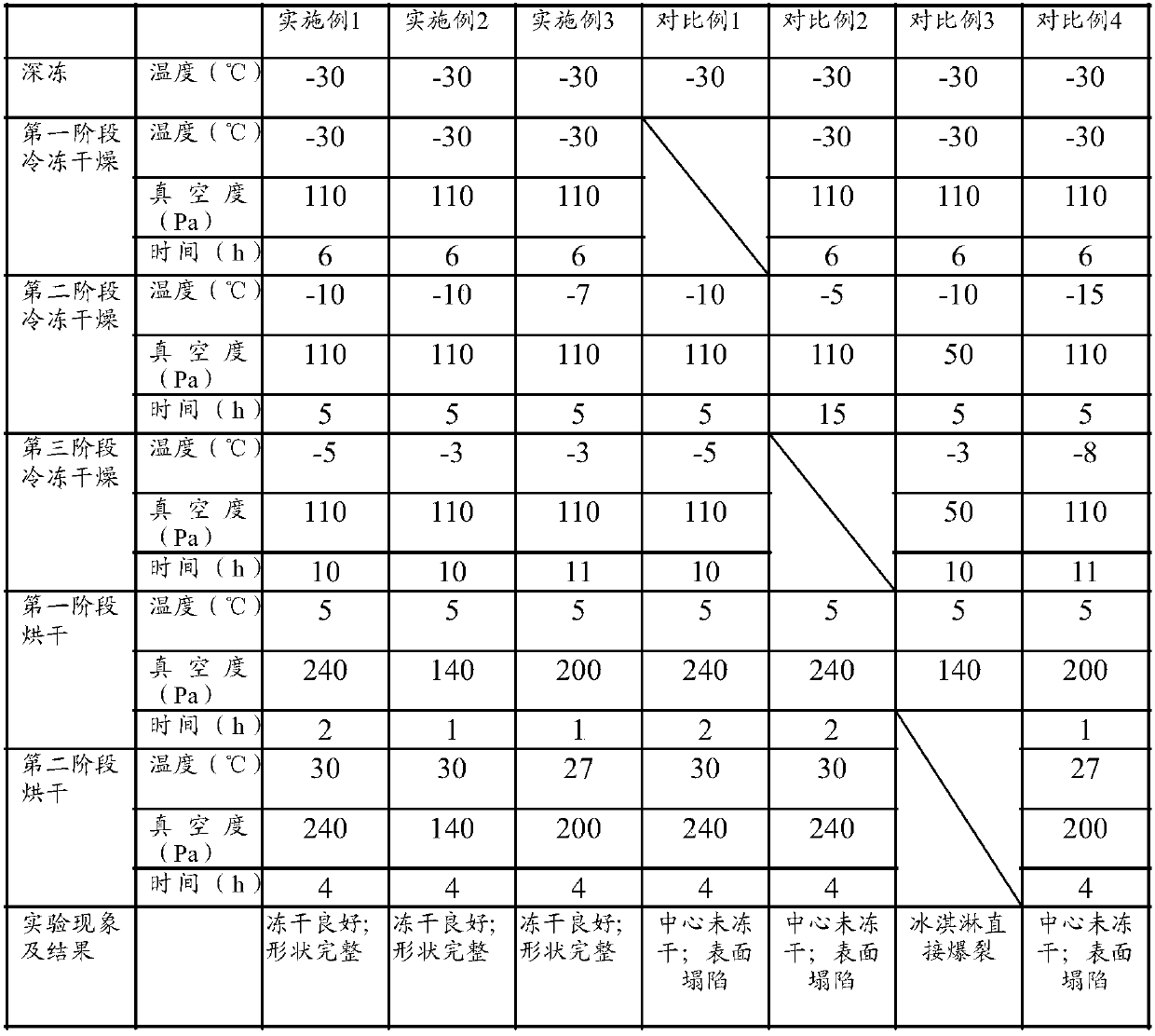

[0067] The ice cream to be freeze-dried provided in Example A is put into a freezing tray, and the interval between adjacent ice creams to be freeze-dried is greater than 10mm. Then put the freezing tray into the freeze-drying chamber of the freeze-drying machine, and connect the temperature sensor to deep freeze to -30°C;

[0068] Set the temperature of the freeze-drying chamber of the freeze-dryer to -30°C, evacuate to make the vacuum degree reach 110Pa, and freeze-dry for 6 hours in the first stage;

[0069] Maintain a vacuum of 110Pa, raise the temperature to -10°C, and freeze-dry for 5 hours in the second stage. The temperature of the center of the ice cream is about -10°C detected by the temperature sensor;

[0070] Maintain a vacuum of 110Pa, raise the temperature to -5°C, and freeze-dry for 10 hours in the third stage;

[0071] Adjust the vacuum to 240Pa, raise the temperature to 5°C, and dry for 2 hours in the first stage;

[0072] Keep the vacuum at 240Pa, raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com