Semi-finished complete denture based on manufactured artificial dentition structure and rapid manufacturing method of complete denture

A technology for prefabricated dentition and complete denture is applied in the field of rapid production of complete dentures, and can solve the problems of not being able to be achieved at one time, numerous procedures, and long time-consuming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present application will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that these examples are only used to more fully explain the features of the present application, rather than limit the claims of the present application.

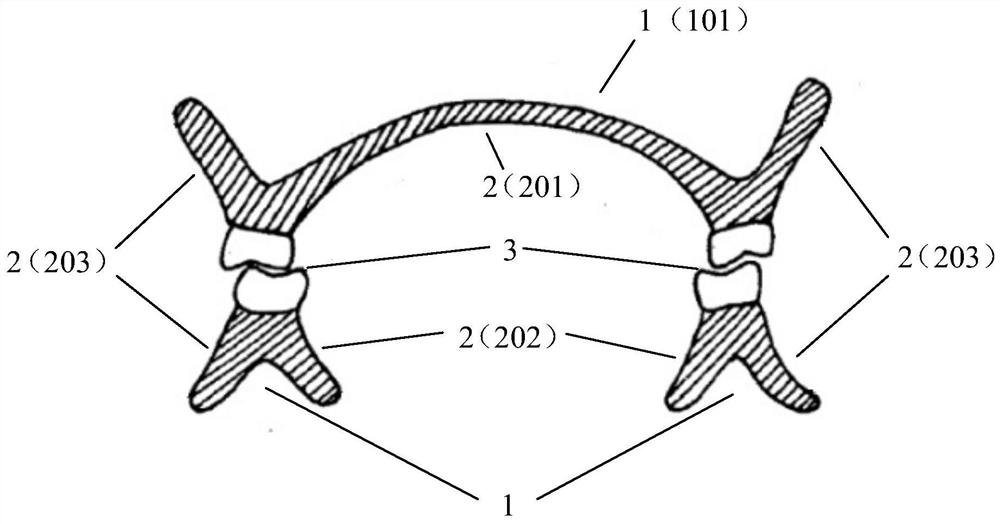

[0035] Such as Figure 3 to Figure 5 As shown, this embodiment adopts a semi-finished complete denture based on the preformed dentition structure, which includes a preformed temporary base and a preformed dentition fixedly combined on the preformed temporary base; the preformed temporary base The thickness is 2-3mm, using the same thermosetting resin material as the clinical complete denture base.

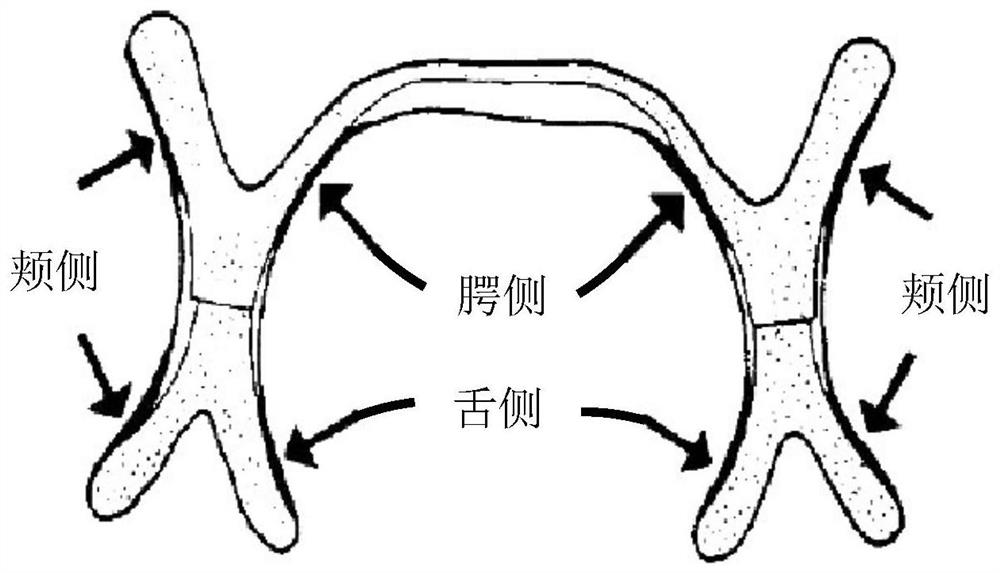

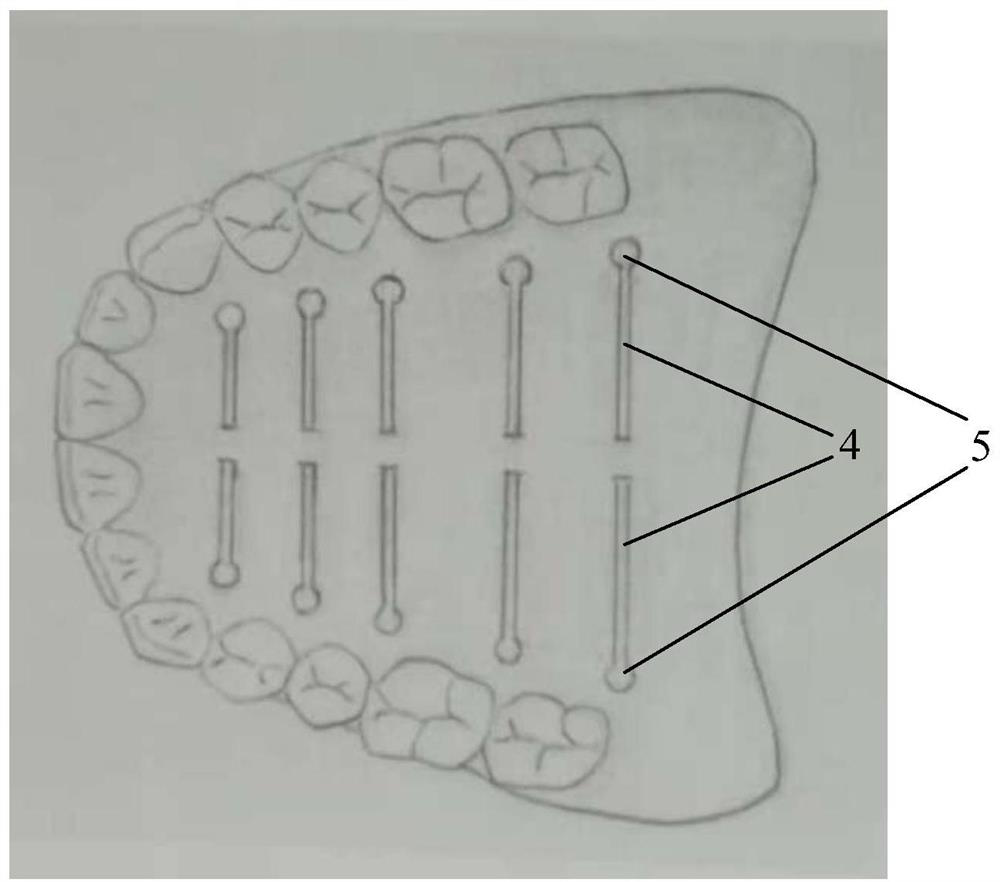

[0036] The palatal surface, buccal surface, and lip surface of the preformed temporary base of the upper jaw and the lingual, buccal, and labial surfaces of the preformed temporary base of the mandible are all provided with multiple strips from the polished surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com