Glue spraying method for light holes of cigarette rod shell

A light-transmitting hole and glue-spraying technology, applied in the field of electronic cigarettes, can solve problems such as inability to prevent dust, uneven surface, and insufficient sealant pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

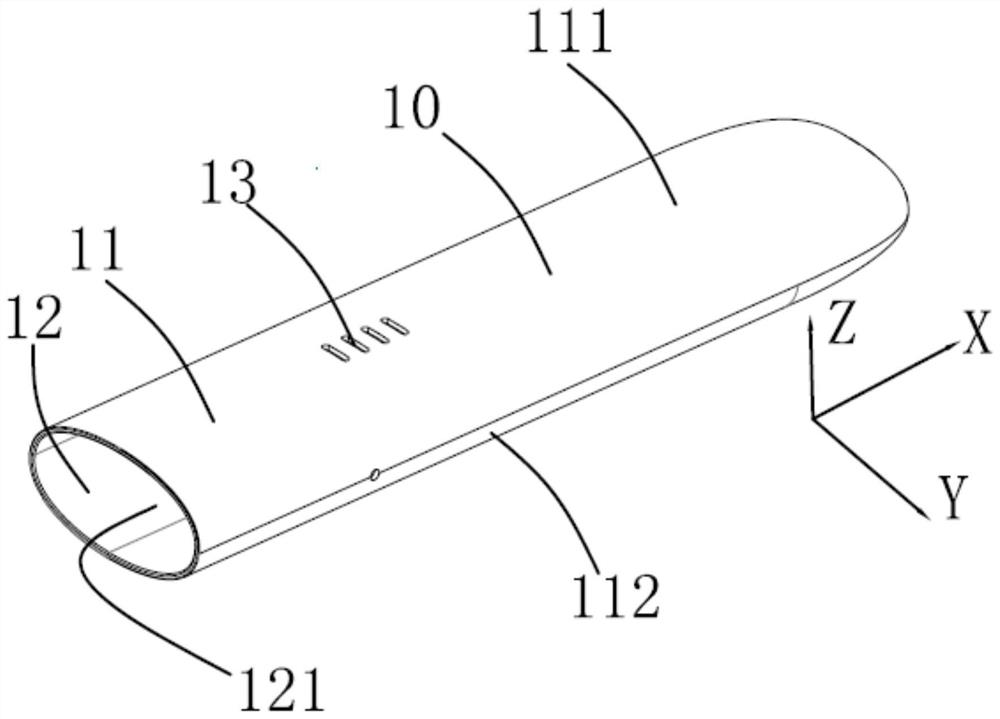

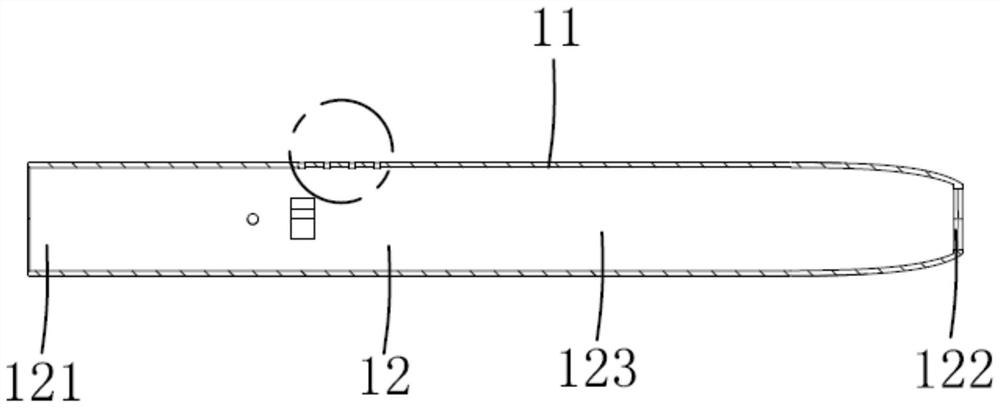

[0041] In this embodiment, the glue spraying method for the light-transmitting hole of the cigarette rod housing includes the following steps:

[0042] S10, the cigarette rod housing 10 is set outside the rod body 221 of the jig 20 and placed on the workbench of the glue spraying machine;

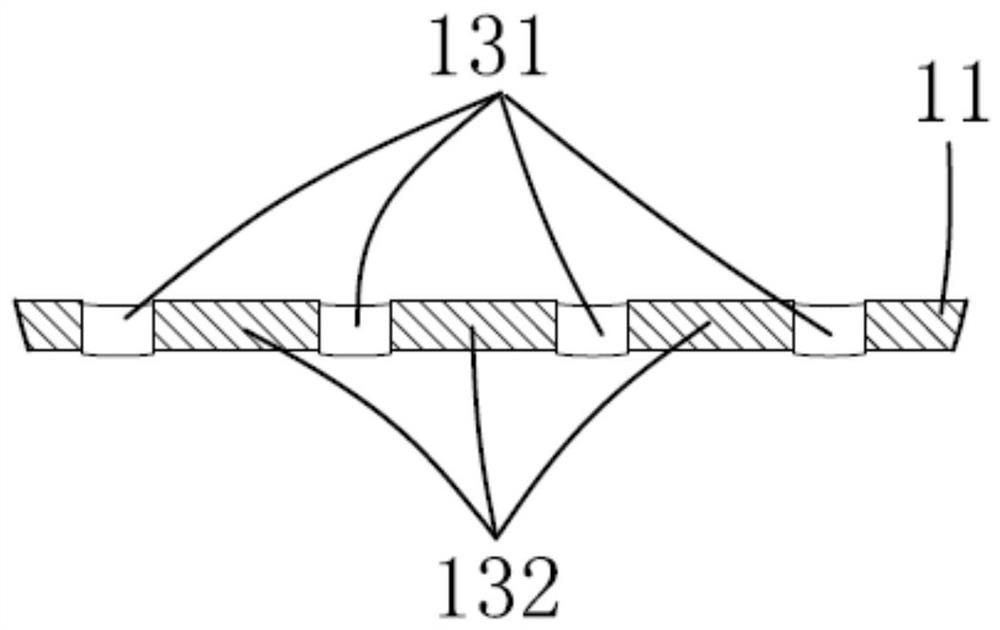

[0043] The glue spraying machine in this step includes a positioning unit, a glue spraying head, a heating device, a processing unit, and the like. The inner surface of the light transmission hole 131 of the cigarette rod housing 10 is closed by the outer surface of the support rod 22 of the fixture 20. The positioning unit is combined with the glue spraying head, and the positioning unit determines the accurate starting position of glue spraying by taking pictures in advance.

[0044] S20, the positioning unit of the glue spraying machine moves to determine the glue spraying starting position of the light transmission hole 131 of the cigarette rod housing 10, and moves the glue spraying h...

Embodiment 2

[0056] In this embodiment, the glue spraying method for the light-transmitting hole of the cigarette rod housing includes the following steps:

[0057] S10, the cigarette rod housing 10 is set outside the rod body 221 of the jig 20 and placed on the workbench of the glue spraying machine;

[0058] The glue spraying machine in this step includes a positioning unit, a glue spraying head, a heating device, a processing unit, and the like. The inner surface of the light transmission hole 131 of the cigarette rod housing 10 is closed by the outer surface of the support rod 22 of the fixture 20. The positioning unit is combined with the glue spraying head, and the positioning unit determines the accurate starting position of glue spraying by taking pictures in advance.

[0059] S20, the positioning unit of the glue spraying machine moves to determine the glue spraying starting position of the light transmission hole 131 of the cigarette rod housing 10, and moves the glue spraying h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com