A kind of milling method of carbon fiber joint arc profile

An arc-shaped, carbon fiber technology, applied in the field of mechanical processing, can solve the problems of low surface processing efficiency, low processing efficiency, and partial residual surface, so as to improve milling efficiency, improve milling efficiency, and reduce the reduction of direction change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions for realizing the purpose of the invention of the present application are further described below through specific embodiments. It should be noted that the technical solutions claimed in the present application include but are not limited to the following embodiments.

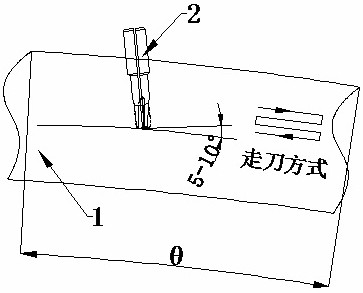

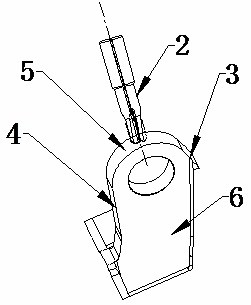

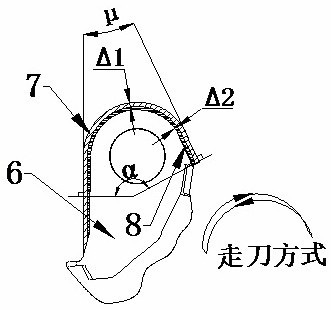

[0028] Refer to the manual attached Figure 2-5 As shown, the present application discloses a milling method for the circular arc profile of a carbon fiber joint, which is specifically realized by the following methods and steps:

[0029] Step 1: Rough milling of circular arc profile and tangent ruled surface, using end mill 2 with tool diameter D≥20mm, bottom angle R≥5mm, and cutting edge made of high-strength PCD material; During the milling process, the swing angle of the machine tool spindle changes continuously according to the change of the normal direction of the profile. The side edge of the tool realizes large allowance milling with a depth of cut Ap ≥ 1.2R, and simultane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com