Side grinding structure and method of hard alloy band saw blade bits

A technology of cemented carbide and band saw blades, which is applied in the direction of metal sawing equipment, tool trimming of sawing machine devices, and metal processing equipment, etc. It can solve problems such as poor side grinding of carbide band saw blades, and achieve side grinding Continuous grinding, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0035] For the convenience of description, the relative positional relationship of each component, such as: the description of up, down, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

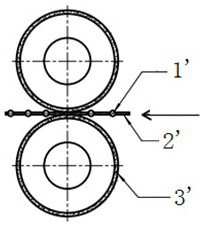

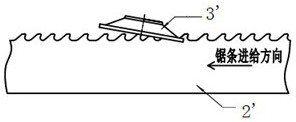

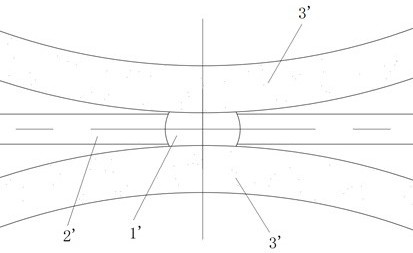

[0036] Such as Figure 4 - Figure 9 As shown, an embodiment of the side grinding structure of the cemented carbide band saw blade head of the present invention includes a saw blade 2 fed at a constant speed, and a cemented carbide cutter head 1 is welded on the tooth tip of the saw blade 2, and the two sides of the saw blade 2 are respectively A grinding wheel 3 for grinding the side of the cemented carbide bit 1 is provided.

[0037] The grinding wheel 3 is a frustum-shaped grinding wheel with a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com