A transition belt cutting bearing device

A bearing device and transition belt technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of irregularity, difference, low test Reynolds number, etc., and achieve the effect of convenient layout and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

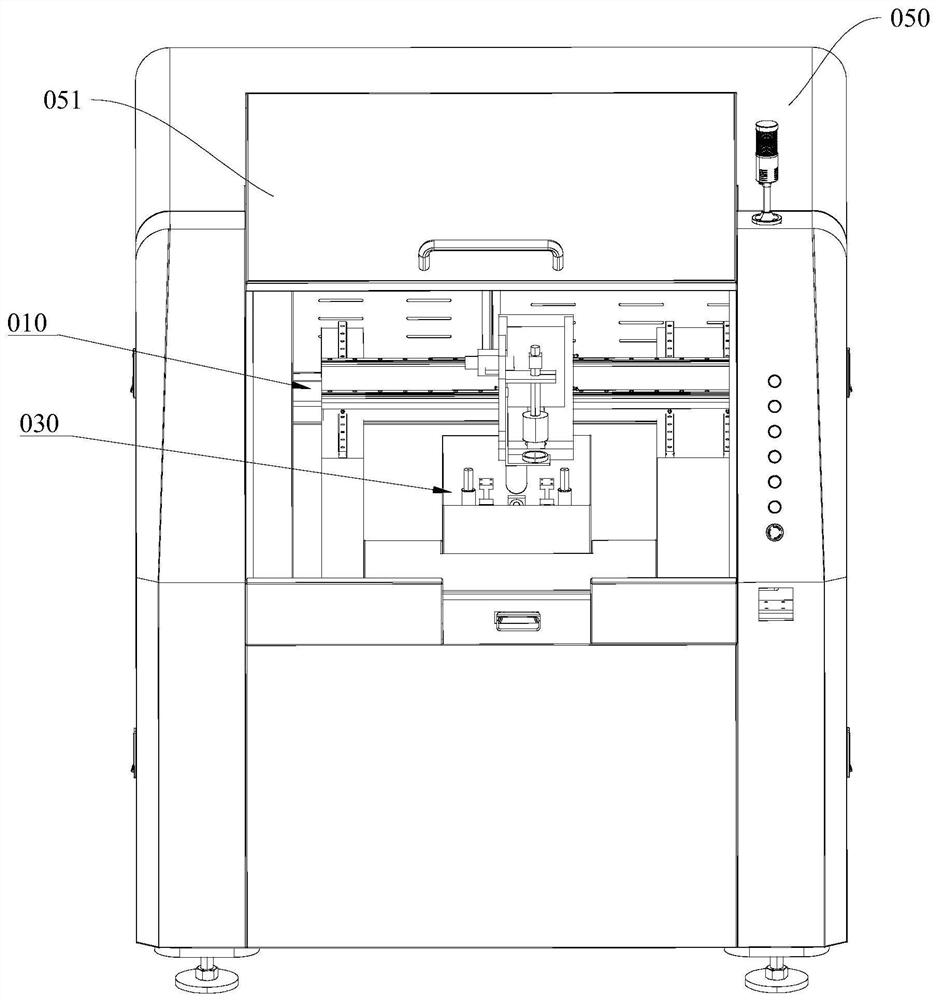

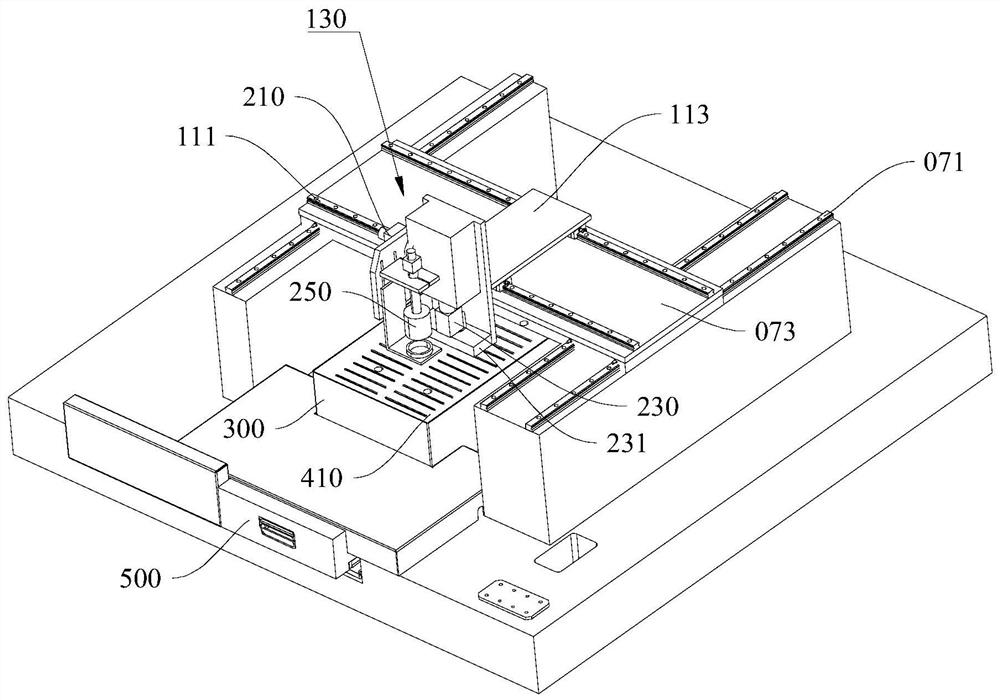

[0044] This embodiment provides a transition zone cutting machine, please refer to figure 1 with figure 2 , including a machine body 050, a transition zone cutting laser emission alignment device 010 and a transition zone cutting carrying device 030;

[0045] The transition belt cutting laser emission alignment device 010 and the transition belt cutting carrier device 030 are installed in the machine body 050, wherein the transition belt cutting carrier device 030 is used to carry the transition belt to be cut, and place the transition belt to be cut stably , and the placement and removal of the transition belt to be cut is realized through the lifting mechanism, and the transition belt cutting laser emission alignment device 010 is used to emit laser light to align the transition belt to be cut on the transition belt cutting carrier device 030 .

[0046] The body 050 is also provided with a flip cover 051 that can be opened and closed. When the flip cover 051 is closed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com