Structural color elastomer based on polyacrylic acid as well as preparation method and application thereof

A technology of polyacrylic acid and methacrylic acid, applied in the direction of coating, etc., can solve the problems of yellowish color, affect the color of structural color elastomer, limit the application, etc., achieve the effect of enhancing color saturation, reducing cracks, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of structural color elastomer based on polyacrylic acid, its preparation method comprises the following steps:

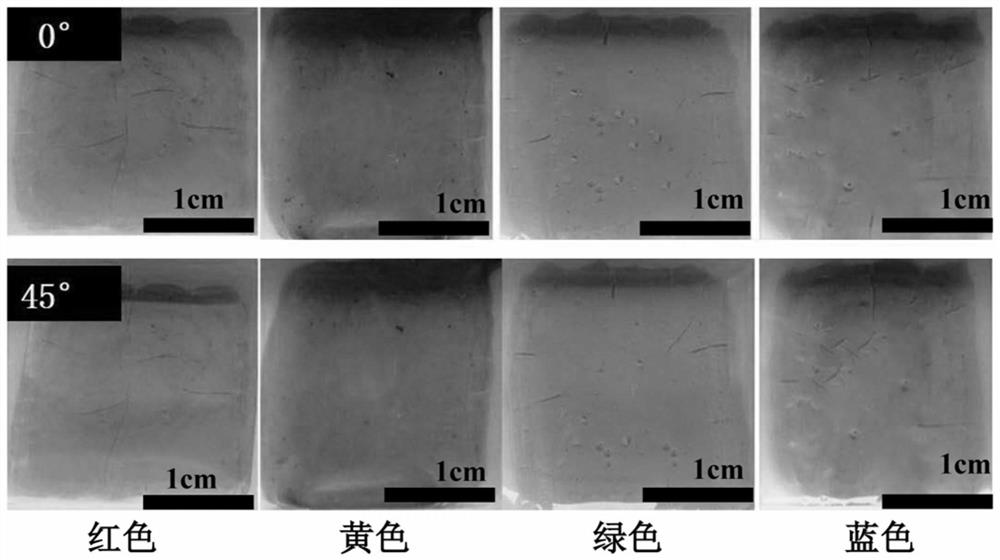

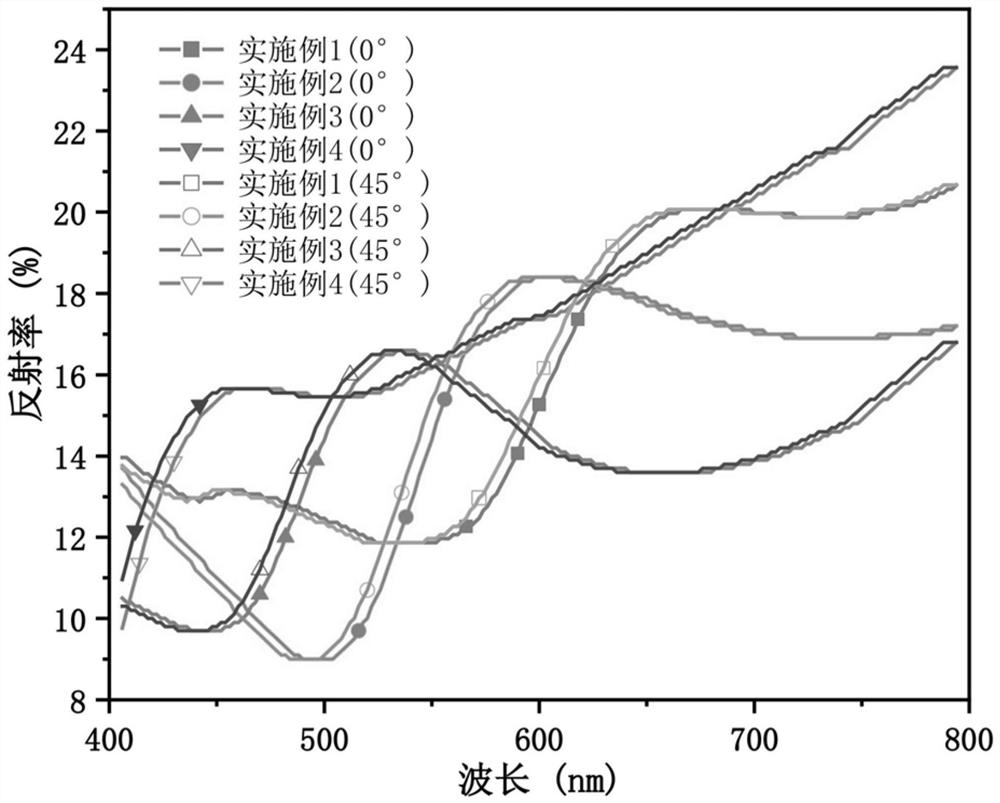

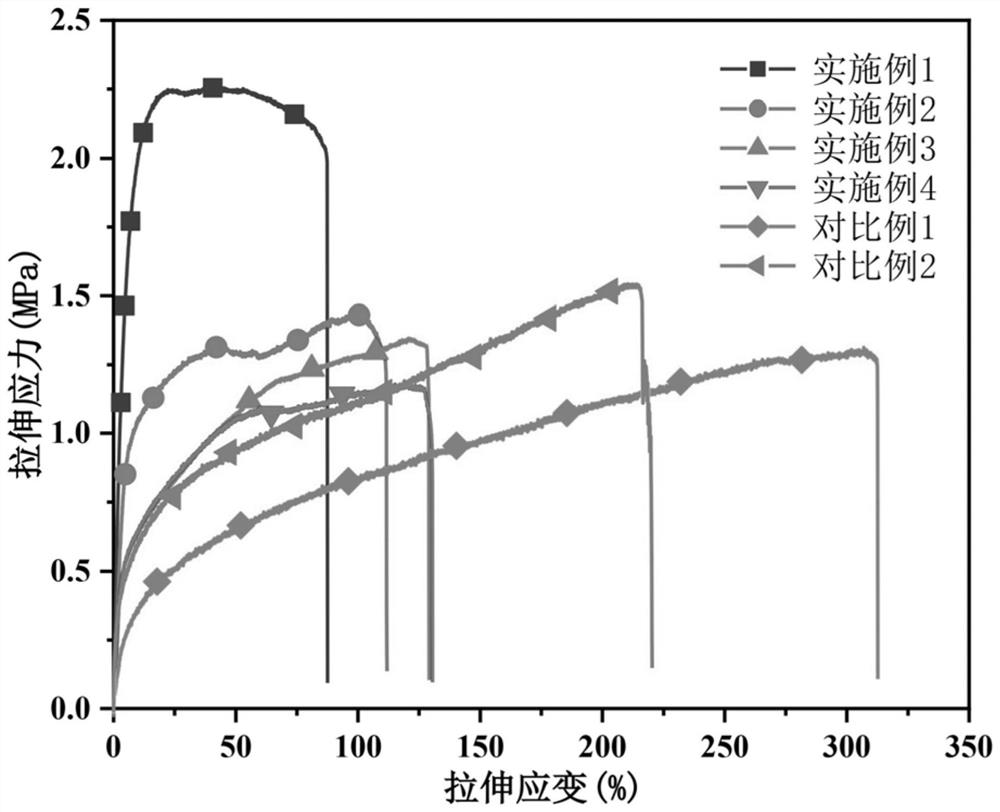

[0055] 1) Mix and disperse 4.8g of polyacrylic acid with a weight average molecular weight of 3000g / mol, 2g of hydroxyethyl acrylate, 3g of hydroxyethyl methacrylate, 1g of methacrylic acid, 13g of water and 8g of ethanol, and then add 0.2 g polyethylene glycol diacrylate with a number average molecular weight of 600g / mol, 0.01g of diallyl disulfide and 0.18g of 2-hydroxy-2-methylphenylpropan-1-one, under dark conditions Stir magnetically for 1 hour to obtain the precursor liquid, then take 2 mL of the precursor liquid and inject it into a square polytetrafluoroethylene mold with a specification of 2.5 cm × 2.5 cm × 0.5 cm, and irradiate it with a UV lamp with a wavelength of 365 nm and a power of 10 W for 1.5 h under the protection of nitrogen, and then Put it into a blast drying oven and dry it at 60°C for 12 hours to obtain a polyacrylic acid elasto...

Embodiment 2

[0060] A kind of structural color elastomer based on polyacrylic acid, its preparation method comprises the following steps:

[0061] 1) The polyacrylic acid of 4.8g weight-average molecular weight 3000g / mol, the hydroxyethyl acrylate of 2.5g, the hydroxyethyl methacrylate of 2.5g, the methacrylic acid of 1g, the water of 13g and the ethanol of 8g are mixed and dispersed, and then Add 0.2 g of polyethylene glycol diacrylate with a number average molecular weight of 600 g / mol, 0.01 g of diallyl disulfide, and 0.18 g of 2-hydroxy-2-methylphenylpropan-1-one, avoid light Under the condition of magnetic stirring for 1 hour, the precursor liquid was obtained, and then 2 mL of the precursor liquid was injected into a square polytetrafluoroethylene mold with a specification of 2.5 cm × 2.5 cm × 0.5 cm, and irradiated with a UV lamp with a wavelength of 365 nm and a power of 10 W for 1.5 h under the protection of nitrogen. , and then placed in a blast drying oven for 12 hours at 60°C t...

Embodiment 3

[0066] A kind of structural color elastomer based on polyacrylic acid, its preparation method comprises the following steps:

[0067] 1) Mix and disperse 4.8g of polyacrylic acid with a weight average molecular weight of 3000g / mol, 3g of hydroxyethyl acrylate, 2g of hydroxyethyl methacrylate, 1g of methacrylic acid, 13g of water and 8g of ethanol, and then add 0.2 g polyethylene glycol diacrylate with a number average molecular weight of 600g / mol, 0.01g of diallyl disulfide and 0.18g of 2-hydroxy-2-methylphenylpropan-1-one, under dark conditions Stir magnetically for 1 hour to obtain the precursor liquid, then take 2 mL of the precursor liquid and inject it into a square polytetrafluoroethylene mold with a specification of 2.5 cm × 2.5 cm × 0.5 cm, and irradiate it with a UV lamp with a wavelength of 365 nm and a power of 10 W for 1.5 h under the protection of nitrogen, and then Put it into a blast drying oven and dry it at 60°C for 12 hours to obtain a polyacrylic acid elasto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap