Tower crane foundation structure

A tower crane foundation and base technology, applied in foundation structure engineering, foundation structure test, soil protection, etc., can solve problems such as economic loss, uneven settlement, tower crane dumping, etc., and achieve the goal of preventing major safety accidents and reducing foundation settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

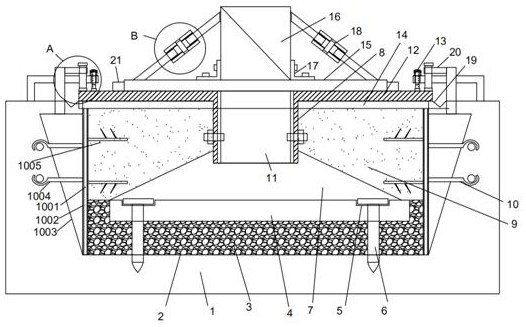

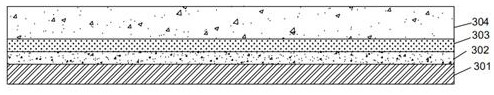

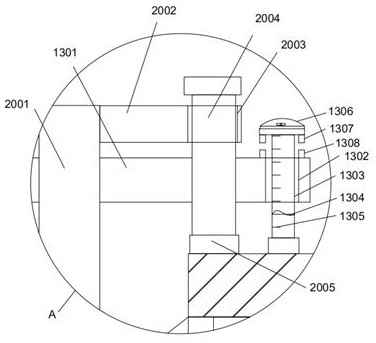

[0033] see figure 1 , a tower crane foundation structure, comprising a foundation 1, the top of the foundation 1 is provided with a pre-buried pit 2, the inside of the pre-buried pit 2 is filled with an anti-settlement base 3, and the top of the anti-settlement base 3 is provided with a pre-embedded pit. Planting plate 4, the two sides of the top of the pre-planting plate 4 are provided with mounting holes 5, and a firm tamper nail 6 is inserted in the mounting hole 5, and a stable base 7 is fixedly installed on the top of the pre-planting plate 4, so The top of the stable base 7 is fixedly connected with a support plate 8, the two sides of the support plate 8 are filled with a concrete layer 9, the side of the concrete layer 9 is provided with a fixing device 10, and the inner side of the support plate 8 is fastened Bolts are fixedly installed with a receiving frame 11, the top of the support plate 8 is fixedly connected with a stable platform 12, the two sides of the stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com