A kind of preparation method of BST/BMN composite film pressure-controlled varactor

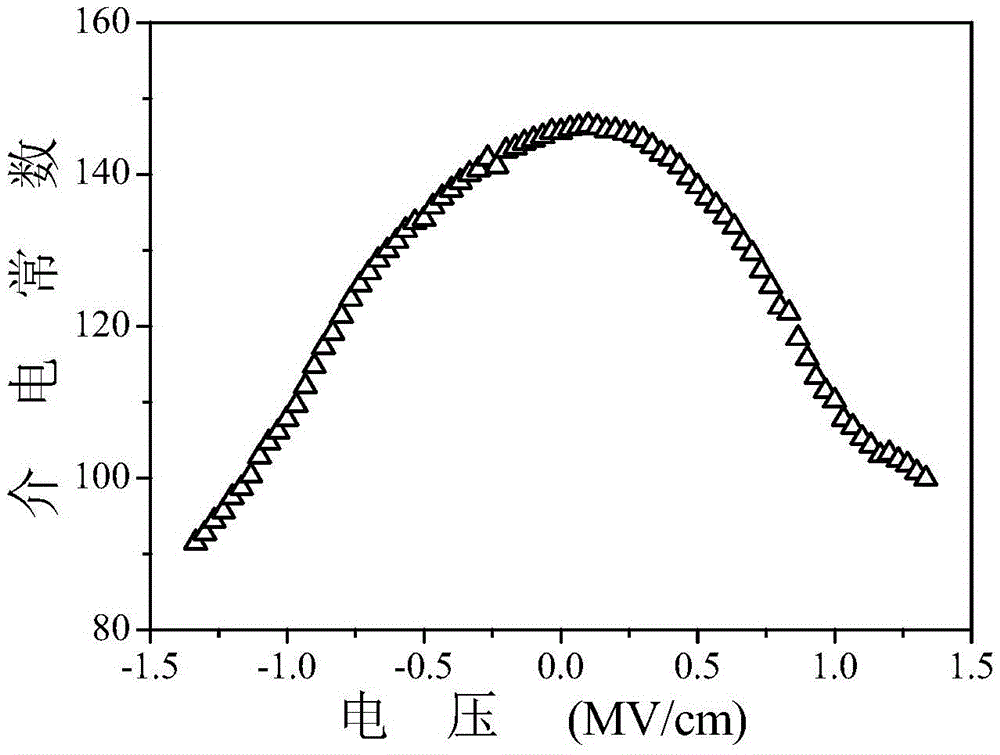

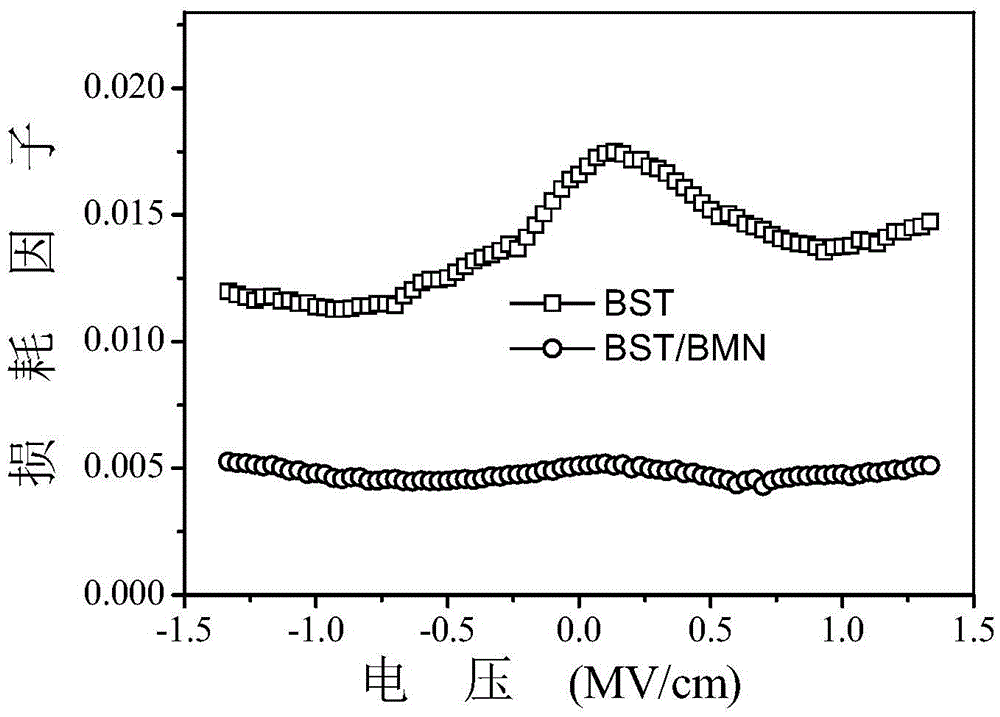

A composite film and varactor technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of low dielectric tuning rate, high dielectric loss of BST film materials, and restrictions on the application of BST films, etc. problem, to achieve the effect of good device stability, moderate tuning rate and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Prepare BMN target and BST target by solid phase sintering method:

[0027] Press Bi with electronic balance 1.5 MgNb 1.5 o 7 The stoichiometric ratio of the corresponding elements is called Bi 2 o 3 , MgO and Nb 2 o 5 (purity is 99%), after fully mixing, press molding under the pressure of 20Mpa, put in box-type electric furnace and gradually heat up to 1150 ℃, and keep warm for 5 hours;

[0028] Press Ba with electronic balance 0.6 Sr 0.4 TiO 3 The stoichiometric ratio of the corresponding elements weighs BaCO 3 , SrCO 3 and TiO 2 , (purity is 99%) after being fully mixed, pressed under the pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1450 ° C, and kept for 10 hours.

[0029] (2) Clean the Pt-Si substrate with N 2 Blow dry and place on magnetron sputtering sample stage.

[0030] (3) Pump the background vacuum of the magnetron sputtering system to 8.0×10 -6 Torr, and then heat the substrate to 400°C.

...

Embodiment 2

[0037] (1) Prepare BMN target and BST target by solid phase sintering method:

[0038] Press Bi with electronic balance 1.5 MgNb 1.5 o 7 The stoichiometric ratio of the corresponding elements is called Bi 2 o 3 , MgO and Nb 2 o 5 (purity is 99%), after fully mixing, press molding under the pressure of 20Mpa, put in box-type electric furnace and gradually heat up to 1150 ℃, and keep warm for 5 hours;

[0039] Press Ba with electronic balance 0.6 Sr 0.4 TiO 3 The stoichiometric ratio of the corresponding elements weighs BaCO 3 , SrCO 3 and TiO 2 , (purity is 99%) after being fully mixed, pressed under the pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1450 ° C, and kept for 10 hours.

[0040] (2) Clean the Pt-Si substrate with N 2 Blow dry and place on magnetron sputtering sample stage.

[0041] (3) Pump the background vacuum of the magnetron sputtering system to 8.0×10 -6 Torr, and then heat the substrate to 400°C.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com