Vault planing and milling collaborative continuous jet grouting diaphragm wall construction method

A construction method and anti-seepage wall technology, which can be used in infrastructure engineering, earth movers/shovels, mechanically driven excavators/dredgers, etc., and can solve the limitation of the efficiency of the retreating construction milling tool to dig the soil layer, etc. problems, to achieve the effect of improving construction efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further explained in detail below in conjunction with the accompanying drawings.

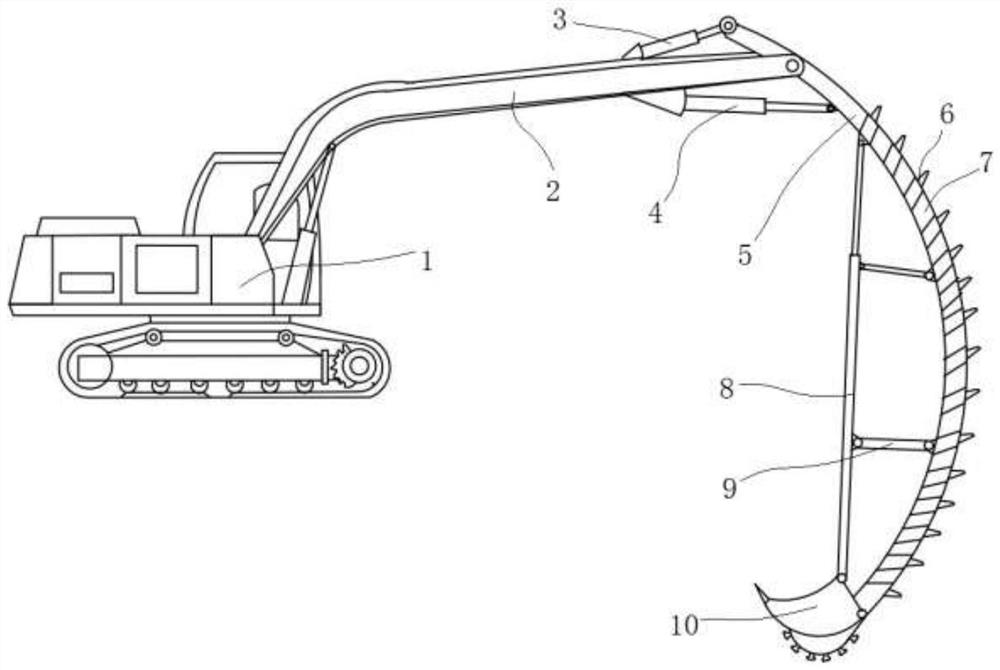

[0031] First of all, the present invention improves the long-arm excavator, such as figure 2 As shown, a long-arm excavator with saw teeth includes an excavator main body 1, a large arm 2, and a small arm 5. The large arm 2 is installed on the main body 1 of the excavator, and the small arm 5 is installed at the front end of the large arm 2. The small arm 5 Set the mounting sawtooth 6 on. The forearm 5 is an arc arm, and the sawtooth 6 is installed on the back of the arc, which can vault and cut the stratum during construction.

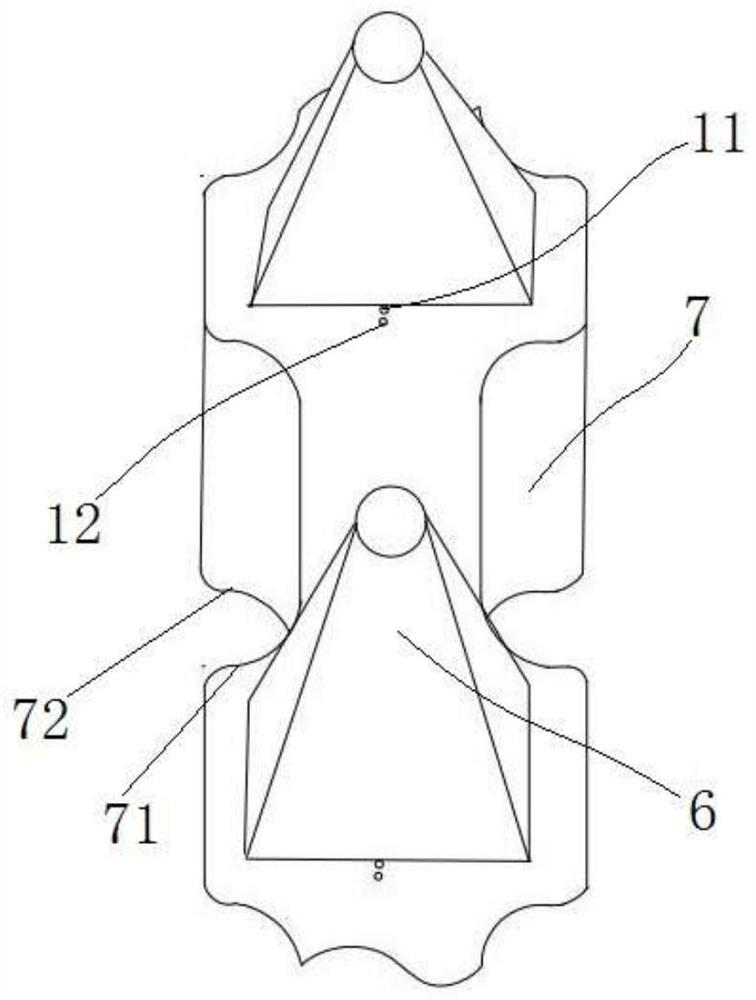

[0032] like image 3As shown, several air nozzles 11 and / or slurry nozzles 12 are installed on the forearm 5, the air nozzles 11 are used to spray high-pressure air flow, and the slurry nozzles 12 are used to spray high-pressure slurry. The formation can be cut by high-pressure fluid together with the saw teeth on the forearm. The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com