Hydrogeological drilling same-diameter repeated water pumping device

A hydrogeological and pumping device technology, which is applied in the direction of earthwork drilling, borehole/well parts, etc., can solve the problems of cumbersome lifting and moving, lack of support structure, and easy toppling, so as to meet the needs of hydrogeological tests and improve the water intake effect , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

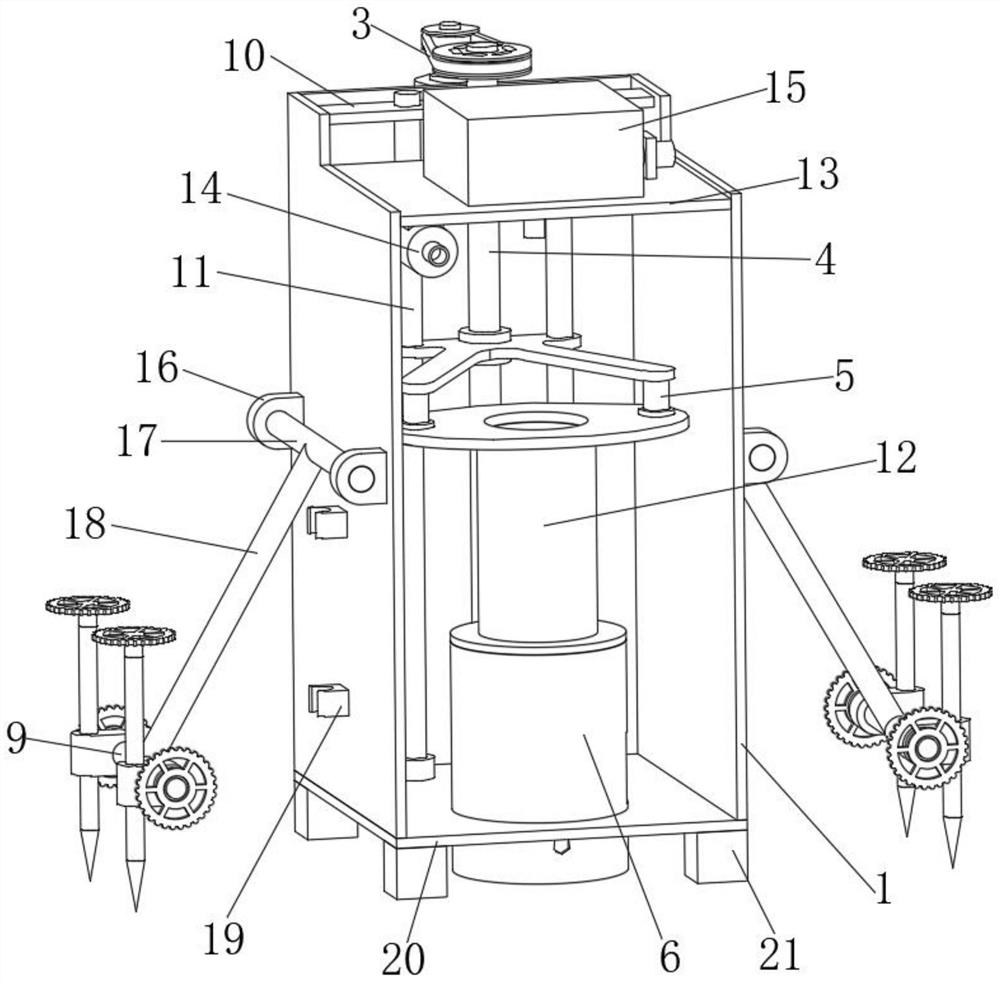

[0032] A kind of hydrogeological drilling same-diameter multiple pumping device, such as Figure 1-3 As shown, the support plate 20 is included, and the upper end of the support plate 20 is fixedly connected with the surrounding shell 1. The surrounding shell 1 is a "匚"-shaped structure, the upper part of the surrounding shell 1 is a stepped structure, and the rear upper part of the inner surface of the surrounding shell 1 is fixedly connected. There is a rear connecting plate 10, the front upper part of the inner side of the enclosure 1 is fixedly connected with a front connecting plate 13, the upper rear end of the enclosure 1 is fixedly connected with a lifting motor 2, and the middle part of the rear connecting plate 10 is interspersed and movably connected with a lifting screw 4. The bottom of the screw rod 4 is interspersed and movably connected with the upper rear part of the support plate 20, and the top of the lifting screw rod 4 and the output end of the lifting motor...

Embodiment 2

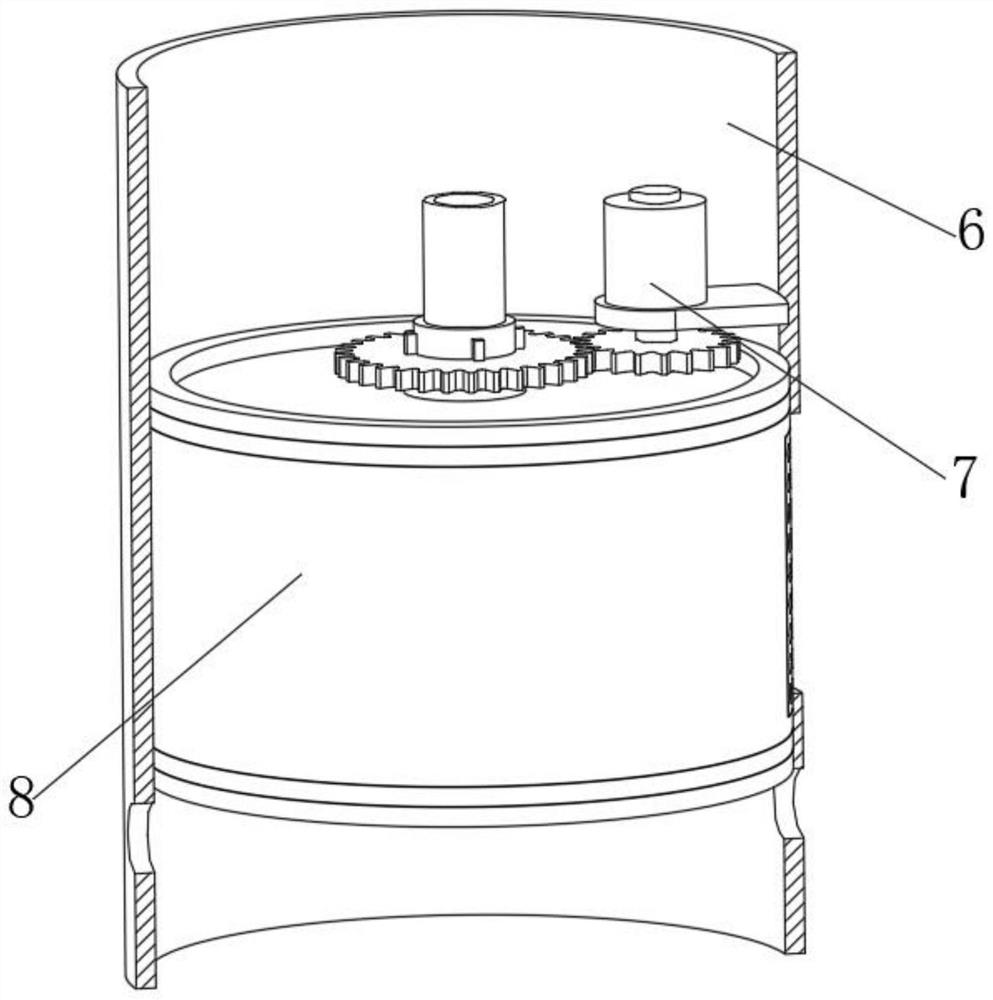

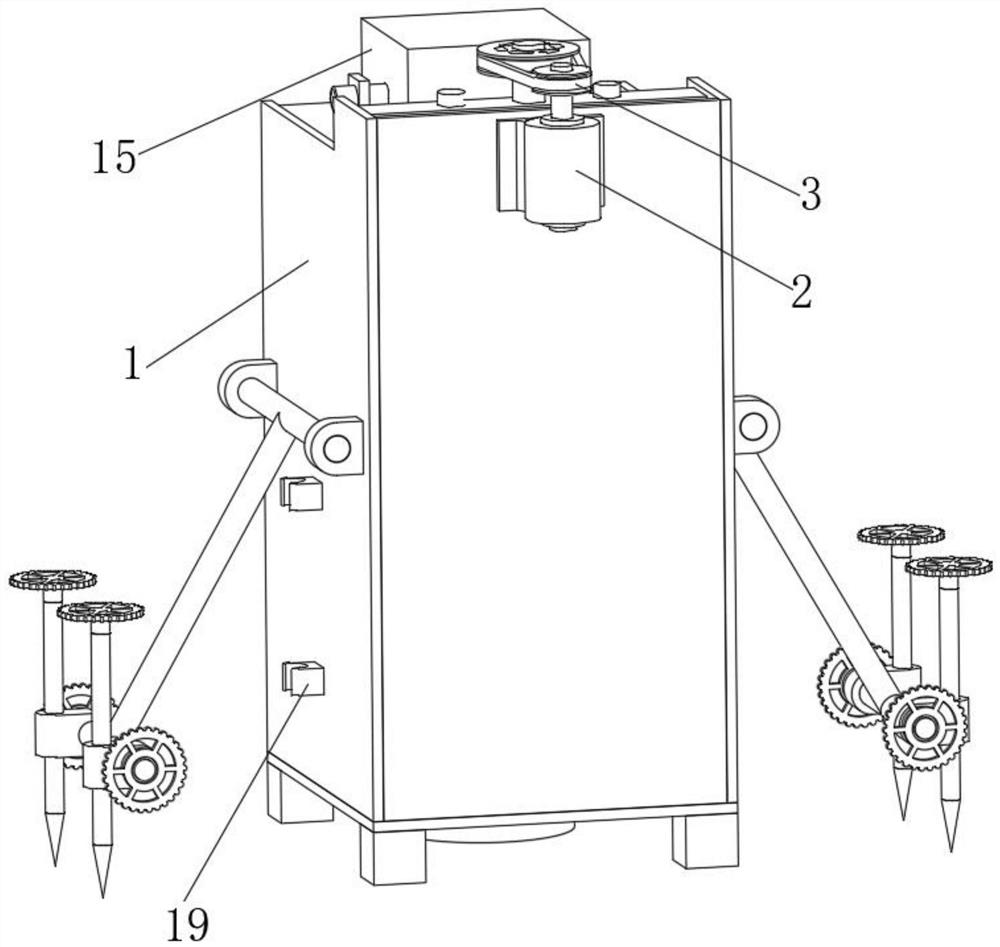

[0035] On the basis of Example 1, as Figure 4-7 As shown, a hydrogeological drilling multiple pumping device with the same diameter includes a support plate 20, the upper end of the support plate 20 is fixedly connected with an enclosure 1, the enclosure 1 is a "匚" shaped structure, and the upper part of the enclosure 1 is stepped structure, the rear upper part of the inner side of the enclosure 1 is fixedly connected with the rear connecting plate 10, the inner side of the enclosure 1 is fixedly connected with the front upper part of the front connecting plate 13, the upper rear end of the enclosure 1 is fixedly connected with the lifting motor 2, and the rear connecting plate The middle part of 10 is interspersed with a lifting screw 4, and the lower part of the lifting screw 4 is interspersed and movably connected with the upper rear part of the support plate 20. The upper part of the lifting screw 4 and the output end of the lifting motor 2 are jointly connected with a bel...

Embodiment 3

[0043] On the basis of Example 1, as Figure 8As shown, a hydrogeological drilling multiple pumping device with the same diameter includes a support plate 20, the upper end of the support plate 20 is fixedly connected with an enclosure 1, the enclosure 1 is a "匚" shaped structure, and the upper part of the enclosure 1 is stepped structure, the rear upper part of the inner side of the enclosure 1 is fixedly connected with the rear connecting plate 10, the inner side of the enclosure 1 is fixedly connected with the front upper part of the front connecting plate 13, the upper rear end of the enclosure 1 is fixedly connected with the lifting motor 2, and the rear connecting plate The middle part of 10 is interspersed with a lifting screw 4, and the lower part of the lifting screw 4 is interspersed and movably connected with the upper rear part of the support plate 20. The upper part of the lifting screw 4 and the output end of the lifting motor 2 are jointly connected with a belt d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com