High-radial-load rotary speed reducer

A technology of rotary reducer and radial load, applied in the field of solar power generation, can solve problems such as torsional deformation of the main beam of the torque tube, and achieve the effect of prolonging the service life of the equipment, low maintenance cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

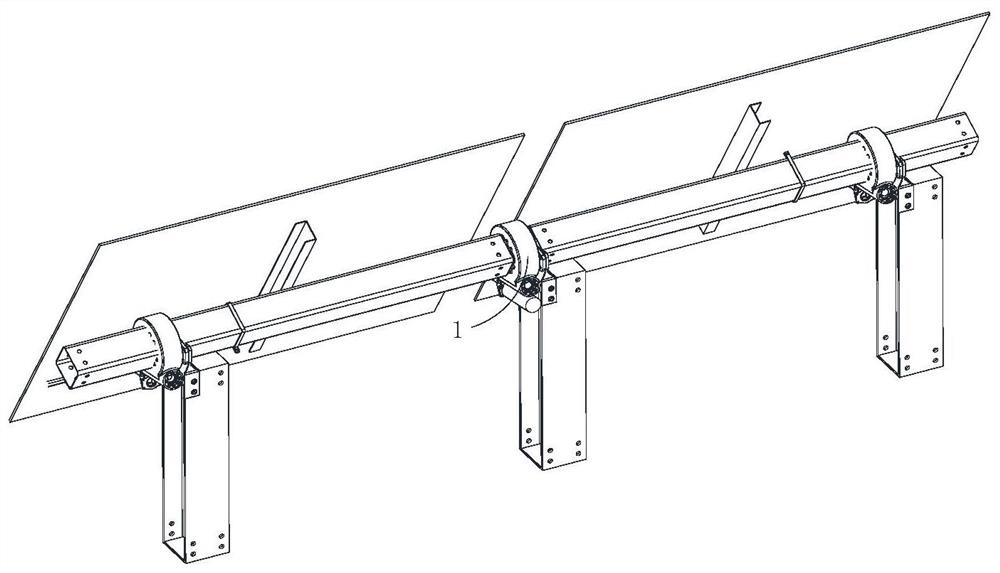

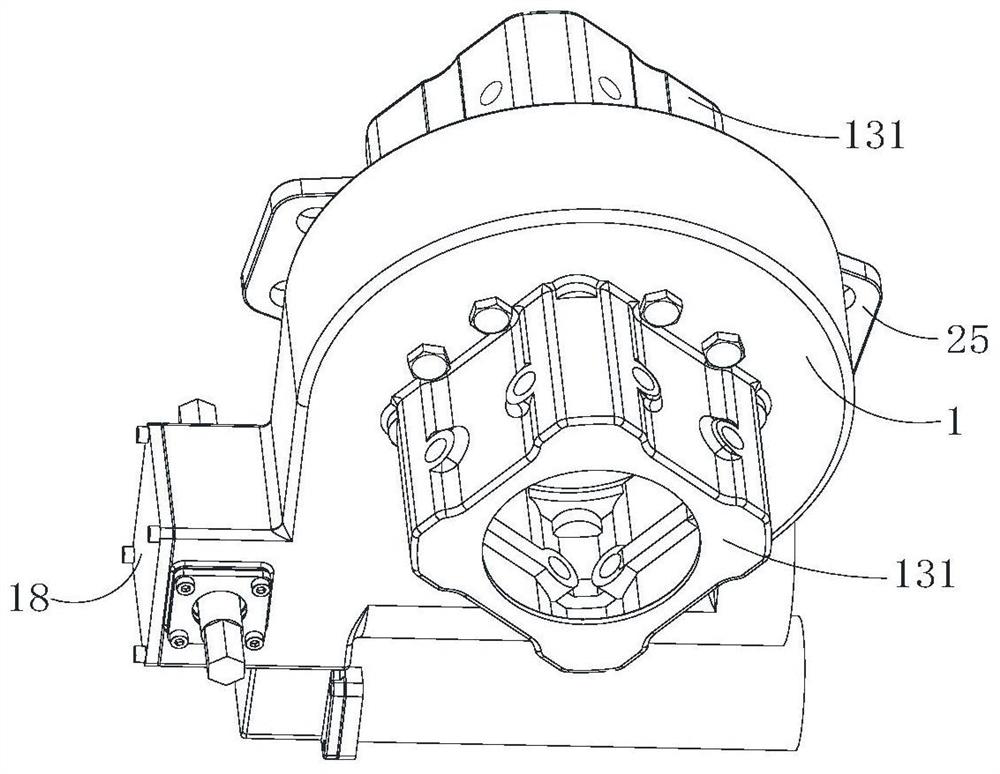

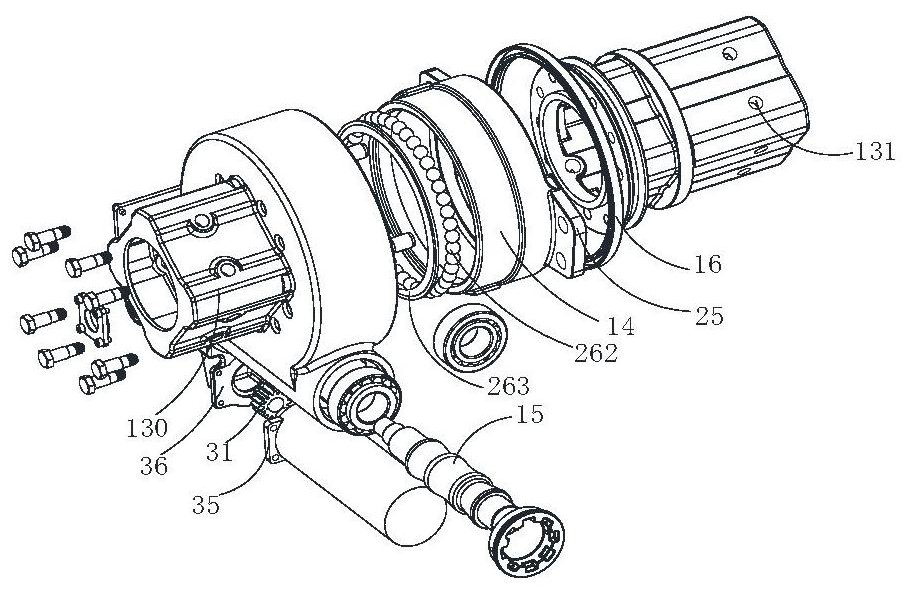

[0083] Such as Figure 1-3 , 6 and 12-13, a high radial load rotary reducer, including the main beam and at least one rotary reducer 1, the number of the rotary reducer 1 can be arranged according to the specific situation, can be 1 or More than 1 setting, the internal structure of multiple rotary reducers 1 is exactly the same setting; one of the rotary reducers is connected to the motor, the motor is controlled by the motor controller, and the motor controller is connected to the motor by a cable; it is connected to the motor The connected rotary reducer 1 is the active rotary reducer, and the other rotary reducers 1 are driven rotary reducers. The torque of the active rotary reducer is transmitted to the driven rotary reducer through the transmission shaft 10, and the active rotary reducer and the driven rotary reducer The reducer rotates synchronously, and then drives the main beam to rotate. The column and main beam mentioned in this article are the existing technology, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com