Online surface defect detection method based on photometric stereo method

A photometric three-dimensional, defect detection technology, applied in optical testing flaws/defects, measuring devices, material analysis by optical means, etc. Simple structure and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

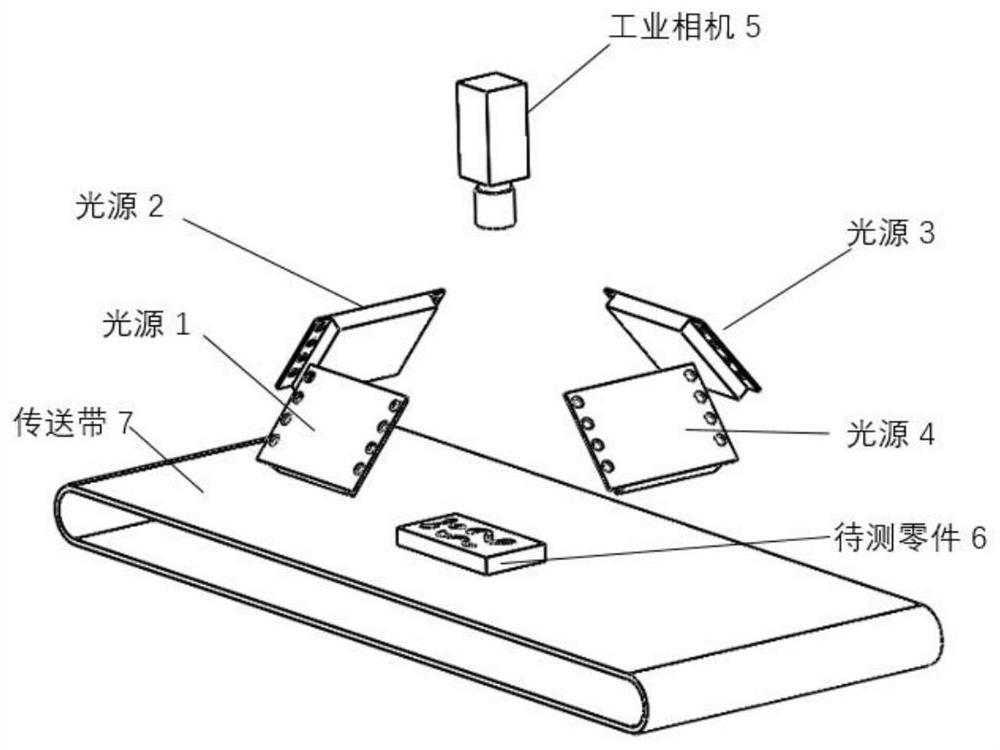

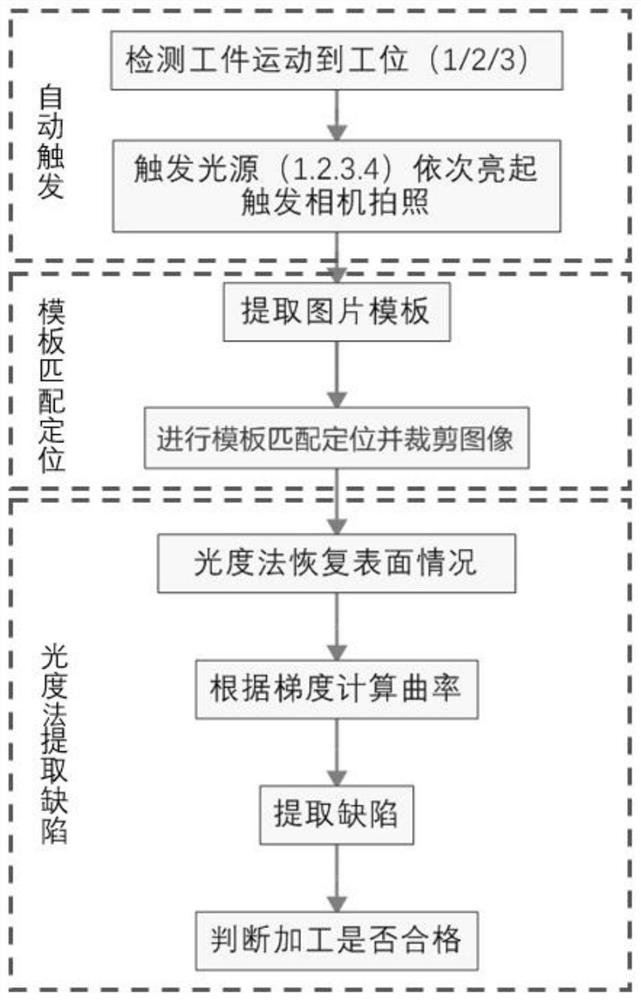

[0018] The present invention designs an online surface defect detection method based on the photometric stereo method. During the detection process, the measured part can move in the assembly line, and the surface curvature map of the part (including two-dimensional and three-dimensional information of the surface of the part) can be quickly obtained. , defect information can be extracted by image processing algorithm. The device used is composed of three parts: camera, conveyor belt and light source. During the inspection process, the parts continue to move with the conveyor belt. When they reach the inspection area, the light sources distributed around the inspection area light up in a cycle, and the camera simultaneously takes photos under the lighting conditions of light sources in different directions. During the whole process, the parts continue to move with the conveyor belt. Since the position of the parts has moved during the process of taking different pictures, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com