Solidification device convenient for demoulding for hazardous waste treatment

A hazardous waste and solidification device technology, applied in the field of hazardous waste treatment, can solve the problems of uneven distribution of waste, unsatisfactory treatment effect, incomplete solidification of hazardous waste, etc., to ensure the effect of distribution and improve the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

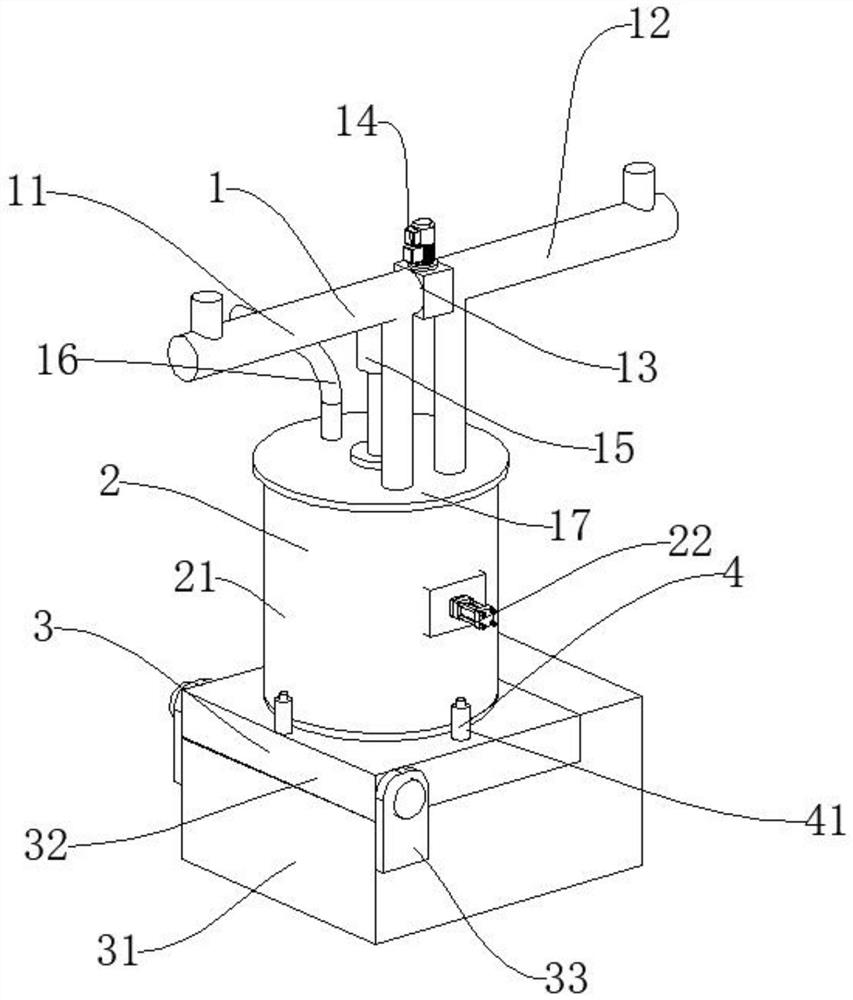

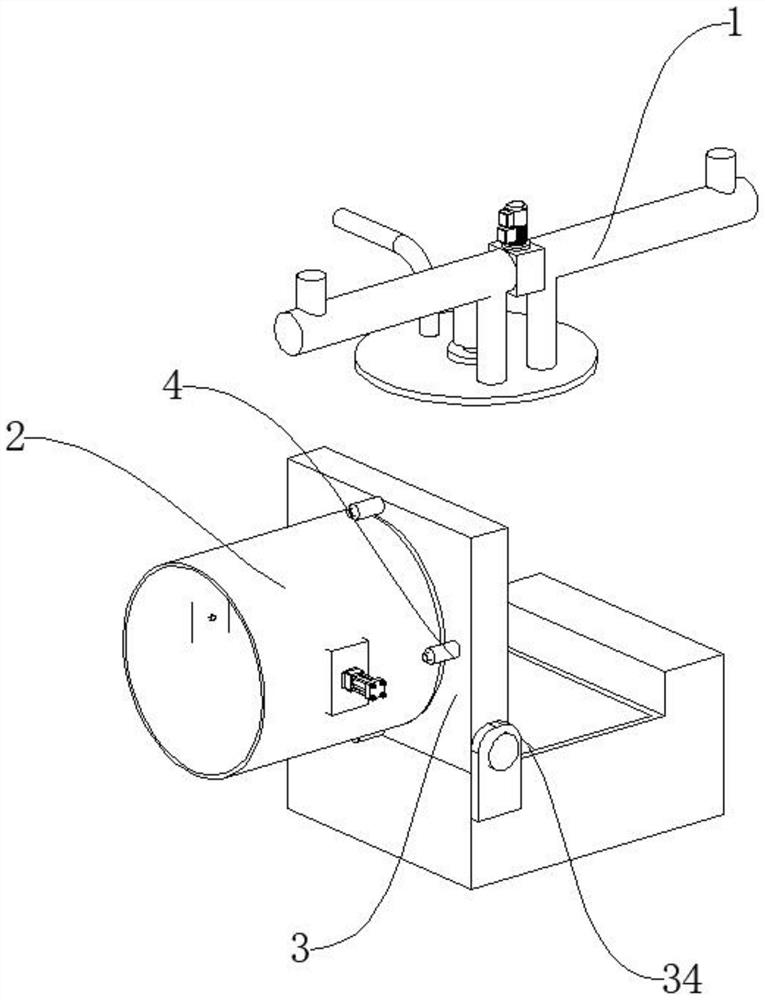

[0048] Such as Figure 1-Figure 7 As shown, an easy-to-release solidification device for hazardous waste treatment, including a feeding mechanism 1 for transmission, a fixing mechanism 2 for curing, and a turning mechanism 3 for unloading, the lower end of the feeding mechanism 1 Connect the fixing mechanism 2, the lower end of the fixing mechanism 2 is connected to the turning mechanism 3, the bottom of the fixing mechanism 2 is equipped with a power mechanism 4, a bottom stabilizing mechanism 5 is arranged between the fixing mechanism 2 and the turning mechanism 3, and a linkage mechanism 6 is connected to the power mechanism 4;

[0049] The feeding mechanism 1 includes a solidified slurry spiral conveying pipe 11, a waste spiral conveying pipe 12, a gearbox 13, and a motor 14. One end of the gearbox 13 is connected with a solidified pulp spiral conveying pipe 11, and the other end of the gearbox 13 is connected with a waste spiral conveying pipe. The motor 14 is installed o...

Embodiment 2

[0056] Such as Figure 8 , the difference between this embodiment and embodiment 1 is:

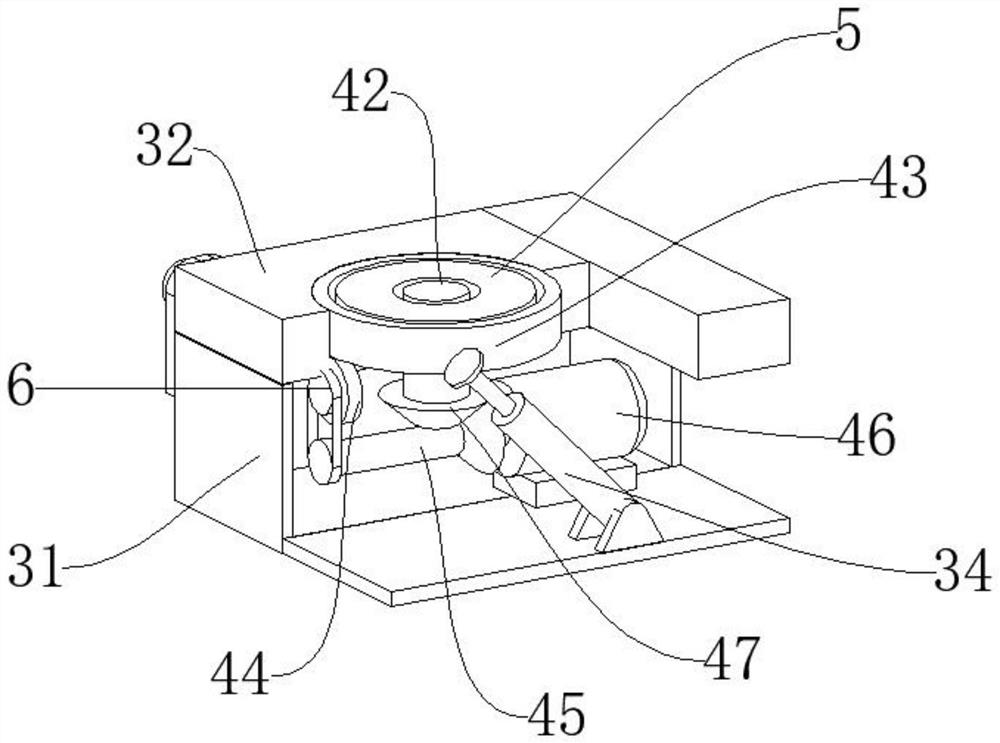

[0057] The linkage mechanism 6 includes a driving bevel gear 611, a linkage bevel gear 612, and a connecting shaft 613. The driving bevel gear 611 is installed on the power main shaft 45 and the driving gear 44 respectively, and a connecting shaft 613 is arranged between the two driving bevel gears 611, and the connecting shaft 613 is connected to the driving bevel gear 611 through the linkage bevel gear 612, and the power spindle 45 drives the driving gear 44 through the driving bevel gear 611 and the linkage bevel gear 612 to cooperate with the gear bar 43 to make the rotating cylinder 21 rotate; the driving bevel gear 611 is keyed to drive the gear 44, The power main shaft 45 and the driving bevel gear 611 play a transmission role.

[0058] Working principle: the clamping cylinder 22 drives the clamping cylinder 23 to merge, and at the same time, after the power motor 46 is started, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com