Automobile grille thermoprinting machine

A technology of hot stamping machine and grid, which is applied in printing presses, rotary printing machines, general parts of printing machinery, etc., can solve the problem that the hot stamping pressure of grids cannot be adjusted, the hot stamping silicone plate is not easy to disassemble, and cannot meet the requirements of bidirectional hot stamping. and other problems, to achieve the effect of quick replacement, saving working time and good hot stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

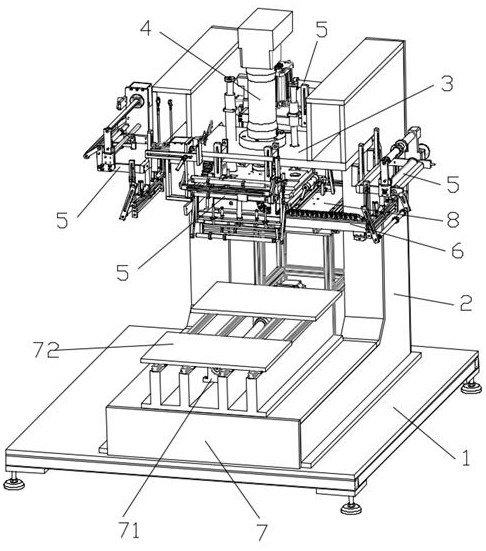

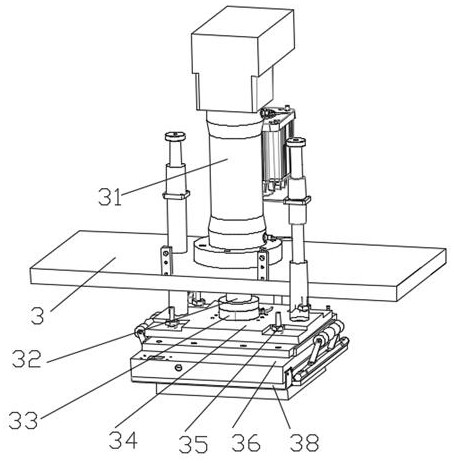

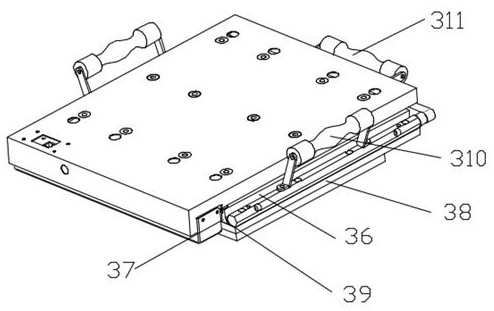

[0027] Such as Figure 1-6 As shown, a car grille hot stamping machine includes: a chassis 1, an integrated hot stamping frame 2 is installed on the upper side of the bottom chassis 1, and hot stamping frames 2 are connected between the integrated hot stamping frames 2. Bottom plate 3, a hot stamping device 4 is installed on the middle side of the hot stamping bottom plate 3, hot stamping foil strip retracting devices 5 are respectively installed on both sides of the front side of the hot stamping bottom plate 3, and the integrated hot stamping frame 2 The hot stamping foil tape retractable device 5 is respectively installed on the left side of the hot stamping base plate 3, and the hot stamping foil tape retractable device 5 on the left side of the hot stamping base plate 3 and the hot stamping foil tape retractable on the front side of the integrated hot stamping frame 2 Foil tape tearing mechanism 6 is respectively installed on the device 5, hot stamping feeding mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com