Front section and rear end limiting structure of automobile roof trim strip

A car roof and limit structure technology, applied in vehicle parts, transportation and packaging, etc., can solve problems such as height difference, distortion, overlap position gap between the luggage rack cover plate and the front section of the roof decorative strip, etc., and achieve recognition Enhanced drop and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with accompanying drawing:

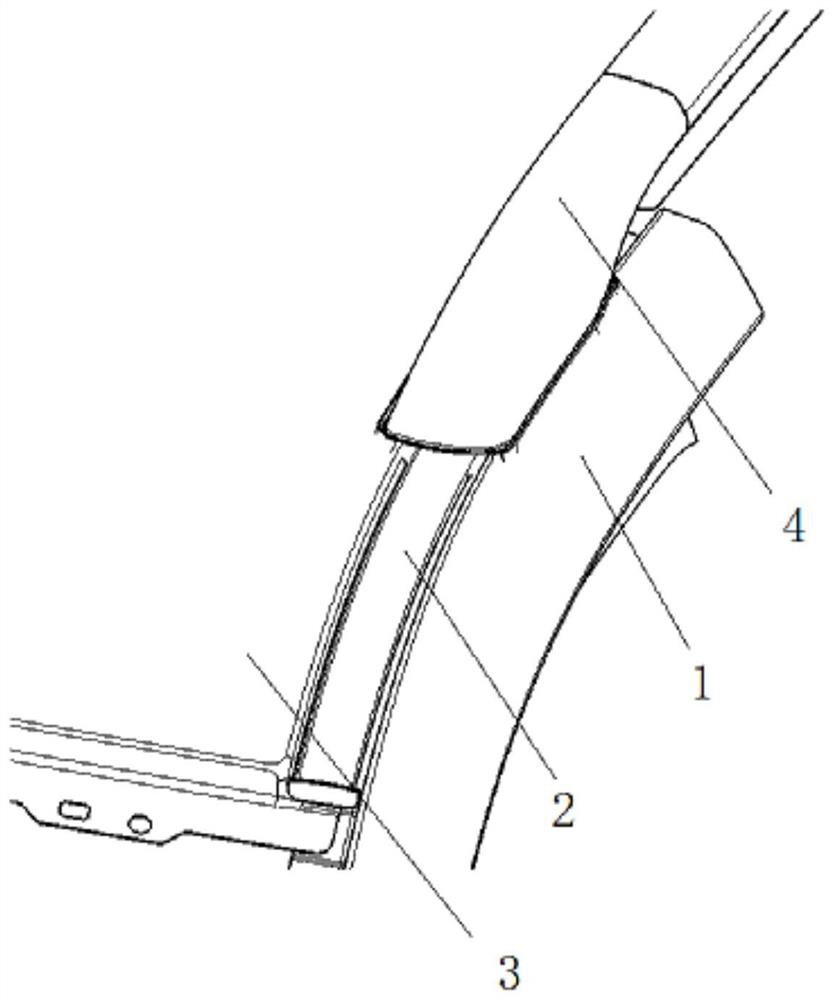

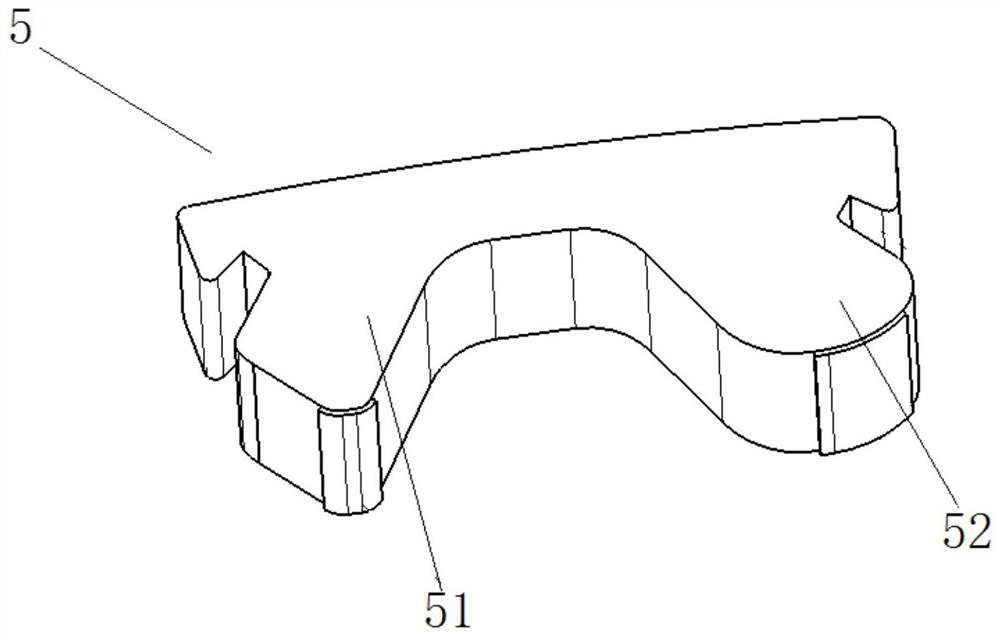

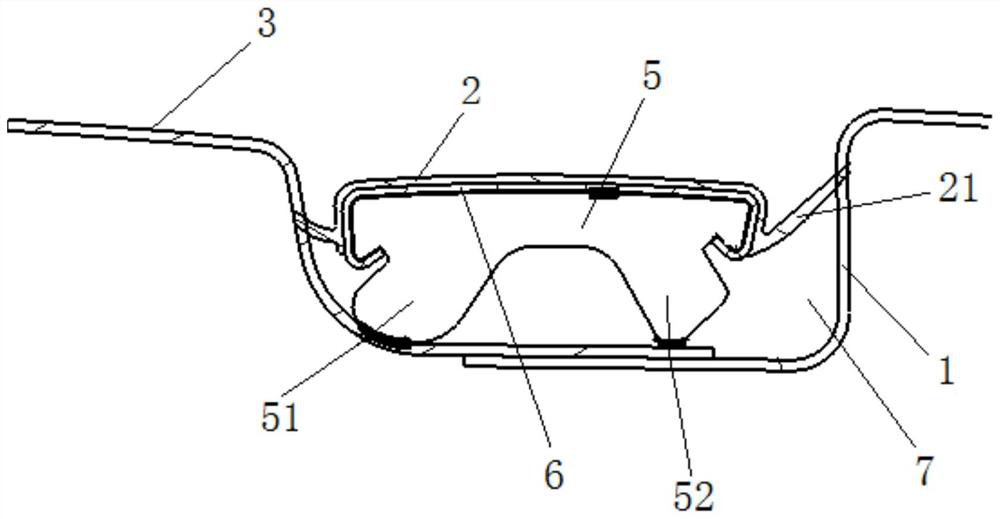

[0024] Such as Figure 2-4 As shown, a front section and rear end limit structure of a roof trim strip for an automobile includes a front section 2 of the roof trim strip and a groove 7 formed by overlapping the side wall outer panel 1 and the roof 3, and also includes a groove 7 arranged on the roof The limit block 5 under the rear end of the front section 2 of the cover decorative strip, the limit block 5 is in the shape of "π", and its lower end is in contact with the inner bottom of the groove 7; A steel belt frame 6 is provided between the bit blocks 5;

[0025] Both sides of the front section 2 of the top cover decorative strip are provided with shielding edges 21, and the shielding sides 21 are in close contact with the two side walls of the groove 7, and the front section 2 of the top cover decorative strip is fixedly connected with the steel strip skeleton 6, and Both...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap