Hanging mechanism, workpiece processing device and workpiece processing system

A hanging and component technology, which is applied in the direction of sealing device, current conducting device, current insulating device, etc., can solve the problem that the hanging device cannot realize barrel plating and rack plating, etc., and achieve good conductive effect, prevent short circuit, and prevent electrification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

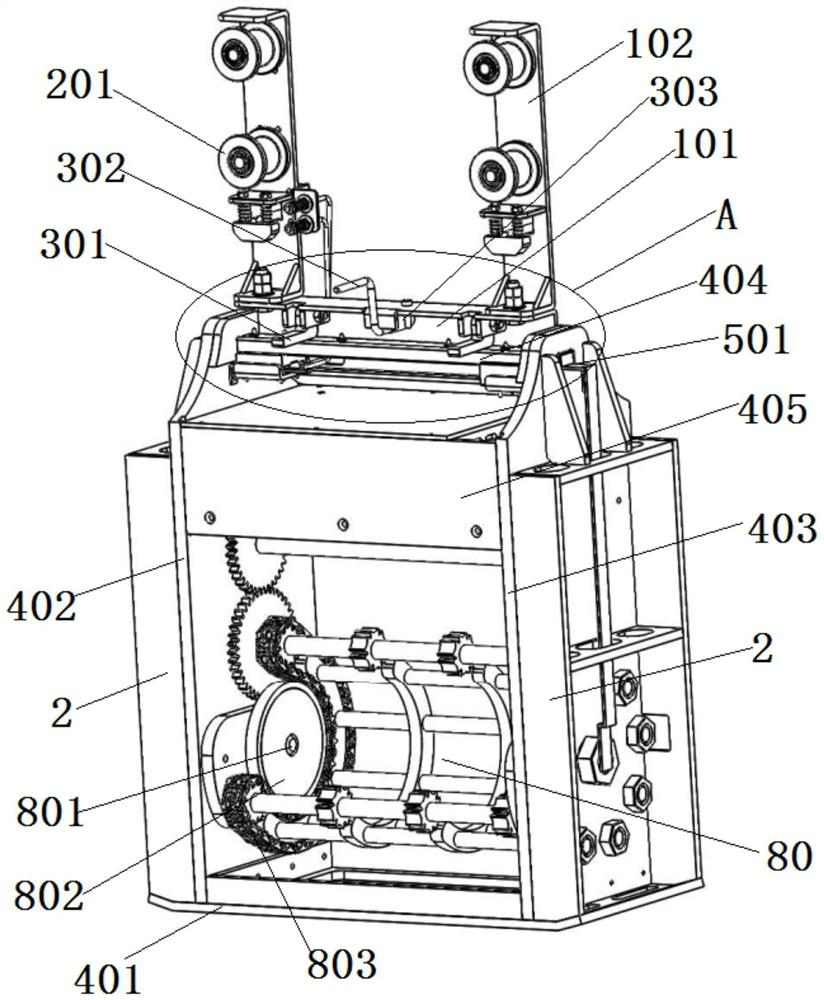

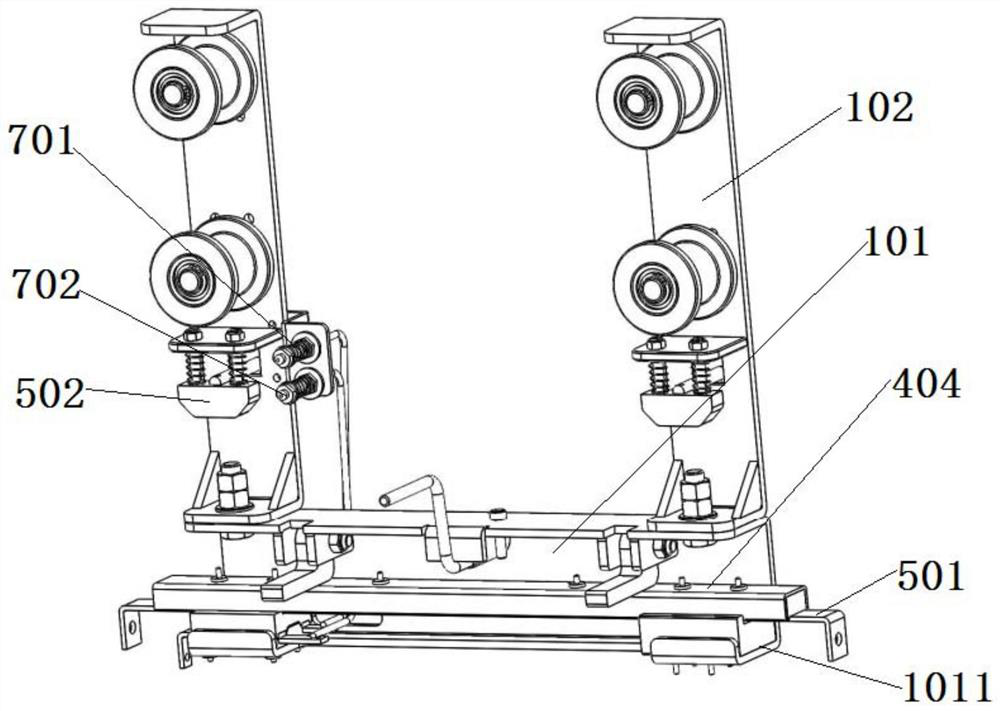

[0084] This embodiment provides a hanging mechanism, such as figure 1 with figure 2 As shown, it includes a spreader and a hanger 4.

[0085] Wherein, the hanger is arranged on the frame and has at least one horizontally extending suspension position 1011; the hanger 4 includes a base 401, a first fixed seat 402, a second fixed seat 403 and a beam 404, the first fixed seat 402 and the second fixed seat 402 The fixing bases 403 are arranged on both sides of the base 401 respectively, and the beam 404 spans between the first fixing base 402 and the second fixing base 403, and the beam 404 is suitable for hanging on the suspension position 1011. 1. A firm installation frame is formed between the second fixing seat 403 and the crossbeam 404, and an installation cavity is formed therein.

[0086] The installation frame of the hanging mechanism of this structure is firmly connected and fixed, and the rack plating mechanism and the barrel plating barrel can be firmly fixed in it, an...

Embodiment 2

[0104] This embodiment provides a workpiece processing device, such as figure 1 As shown, it includes the suspension mechanism in Embodiment 1. The installation frame of the hanging mechanism of the workpiece processing device with this structure is firmly connected and fixed, and the hanging plating mechanism and the barrel plating barrel can be firmly fixed inside it, and the barrel plating can be realized conveniently on the same workpiece processing device. The switching between plating and rack plating does not require two separate sets of electroplating equipment to perform barrel plating and rack plating on workpieces, saving the manufacturing cost of electroplating equipment and saving the floor space of electroplating equipment.

[0105] Specifically, the workpiece processing device further includes two first conductive shafts 801 , two first conductive plates 802 and an open roller 80 . Wherein, two first conductive shafts 801 are arranged on the first fixed seat 40...

Embodiment 3

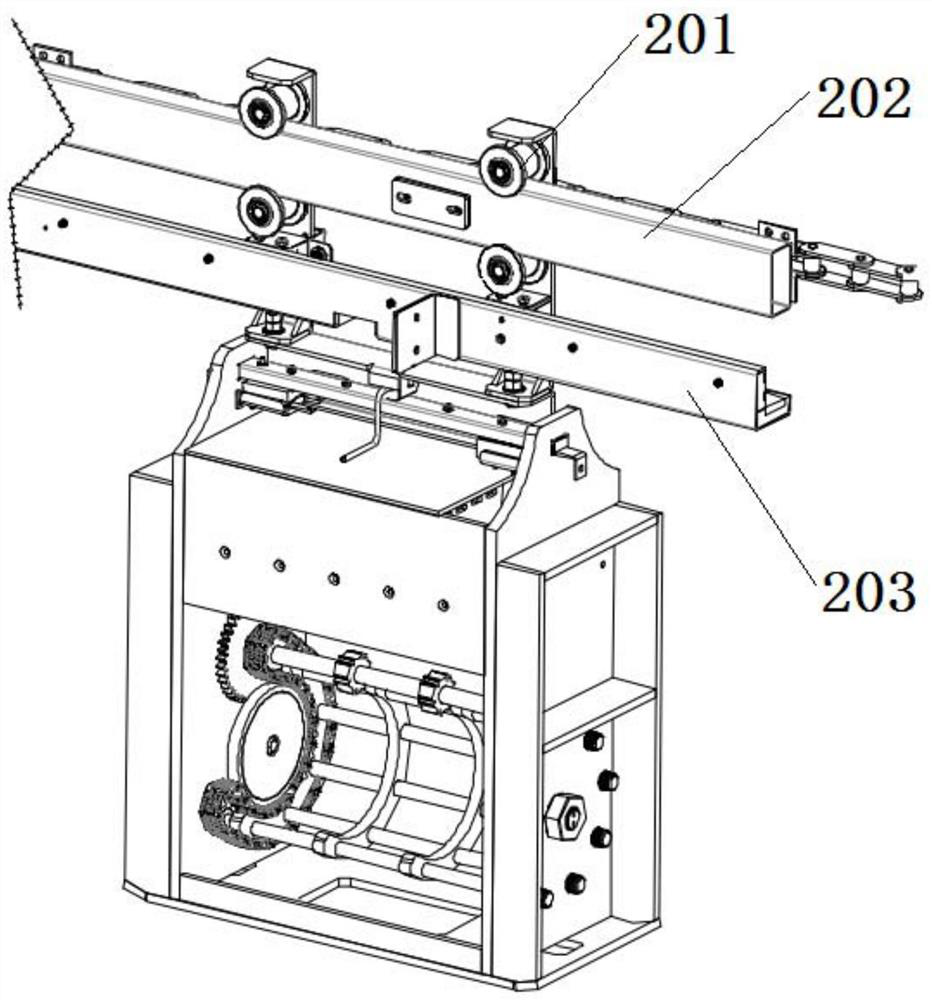

[0113] This embodiment provides a workpiece processing system, including at least one container 1 , at least one hanging mechanism and several sealing components 2 . Hanging mechanism comprises hanger 4.

[0114] Among them, at least one wall of the container is provided with a sealing passage 3; several sealing parts 2 are arranged at intervals in the sealing passage 3; On the wall; any one of the sealing part and the container is driven by the driving mechanism to pass through any sealing passage, and any sealing part is suitable for sealingly passing through any sealing passage, so as to drive the workpiece arranged on the corresponding sealing part Or the hanging mechanism passes through the sealing channel; in the moving direction of the sealing part or the container, the distance between any two adjacent sealing parts is L1i, the length of any sealing channel is L0i, between L1i and L0i Satisfy: L0min≥L1max, wherein L1max is the maximum value among all L1i, L0min is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com