Towering vibration reduction chimney with inerter device

A technology for chimney and inertial container, which is applied to building components, building types, and anti-vibration. The effect of reducing the structural response and displacement response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

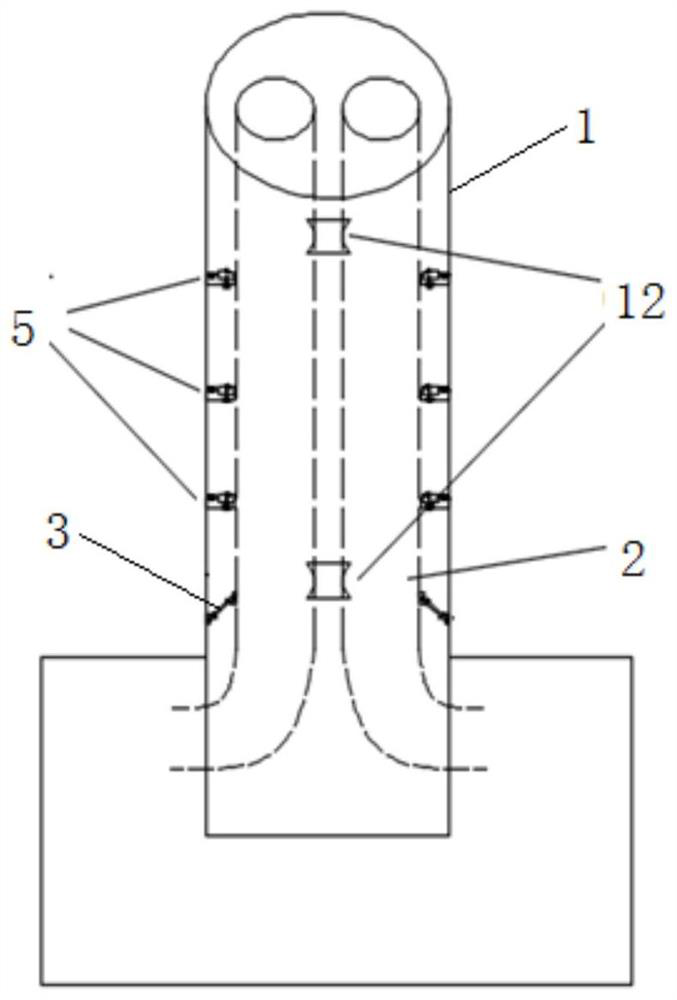

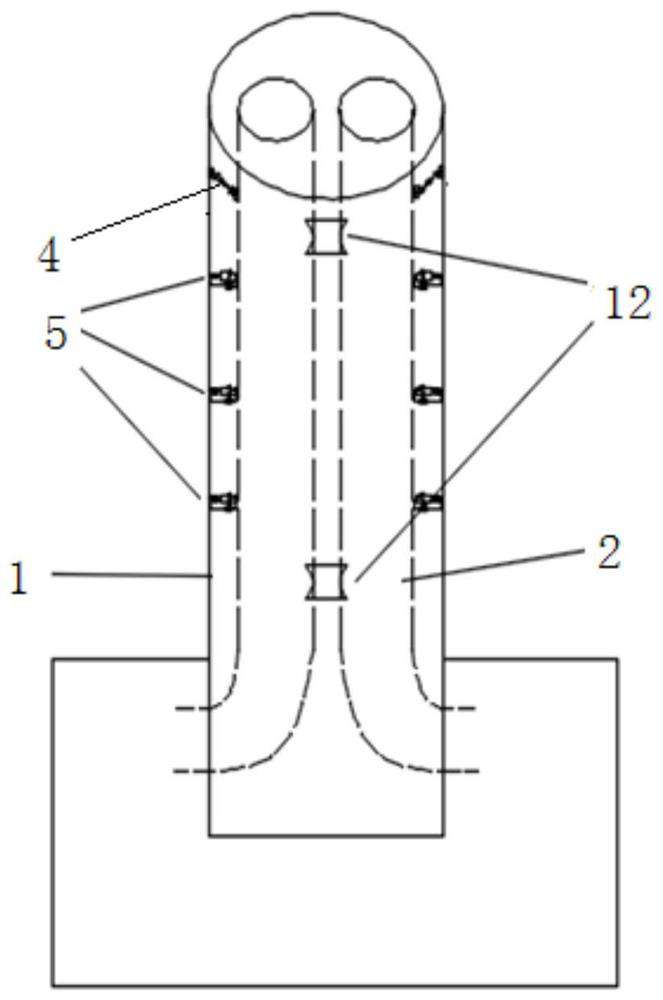

[0029] The present invention provides a towering vibration damping chimney with inertial capacity device, such as figure 1 and figure 2 As shown, including the chimney outer tube 1 and the chimney inner tube 2, the chimney outer tube 1 and the chimney inner tube 2 are connected by a load-bearing rod 3 or a load-bearing spring 4, and the chimney outer tube 1 and the chimney inner tube 2 are also connected by inertial capacity device 5.

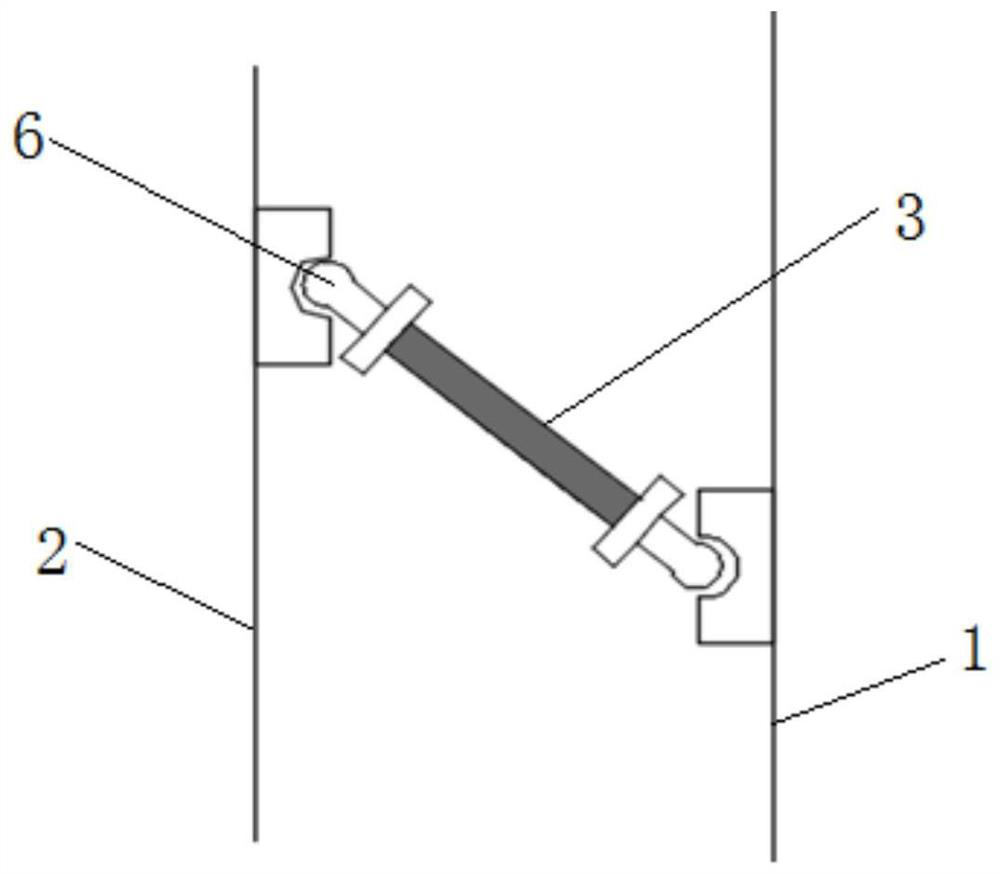

[0030] like image 3 As shown, the two ends of the load-bearing rod 3 are spherical hinges 6, one end is connected to a certain part of the bottom section of the inner cylinder 2 of the chimney, and the other end is supported at a position near the bottom of the outer cylinder 1 of the chimney. like Figure 4 As shown, the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com