Linear reciprocating piston type compressor and using method thereof

A linear reciprocating, piston-type technology, used in piston pumps, liquid variable-capacity machinery, mechanical equipment, etc., can solve the problems of increased wear and increased power consumption of compressors, and achieve increased wear, reduced wear, and reduced impact wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

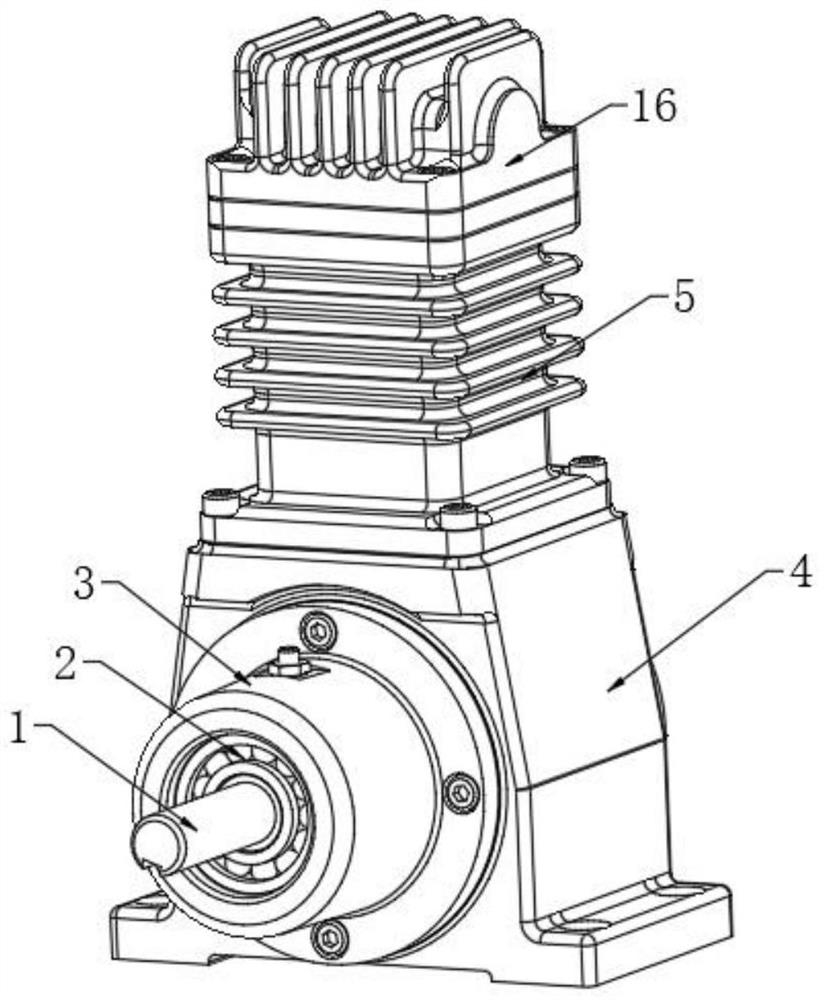

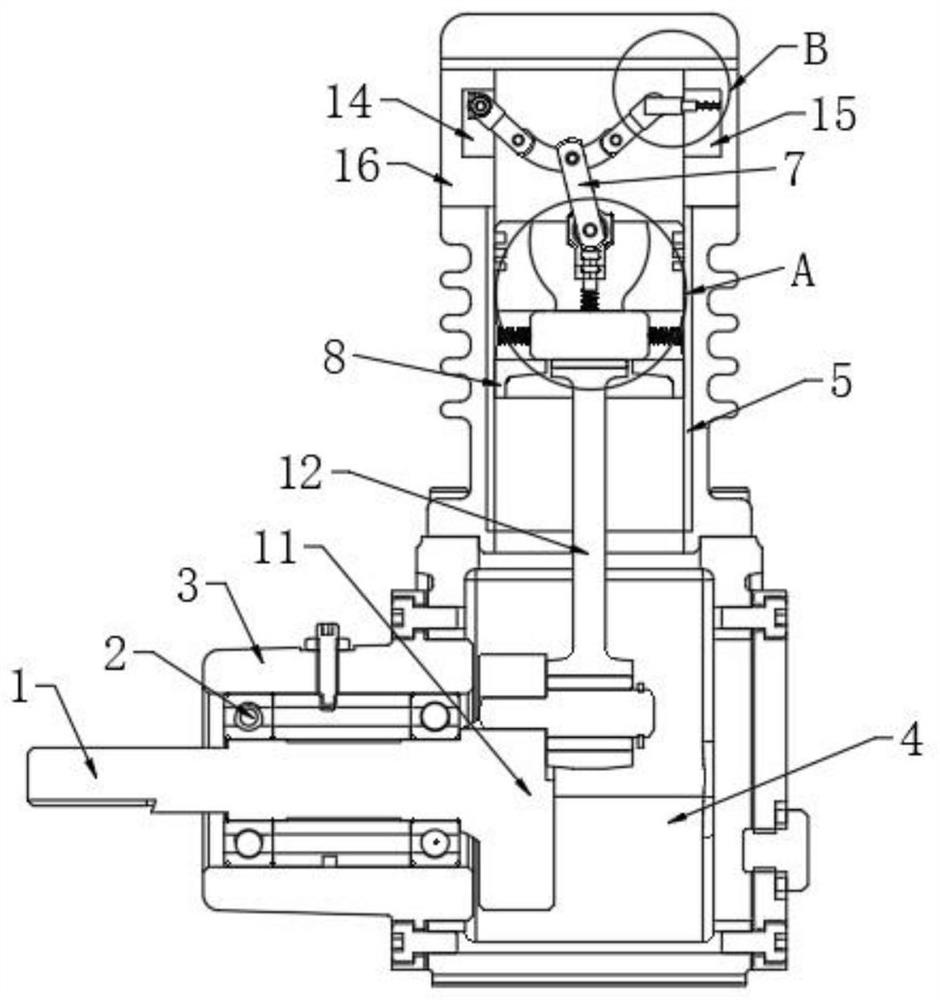

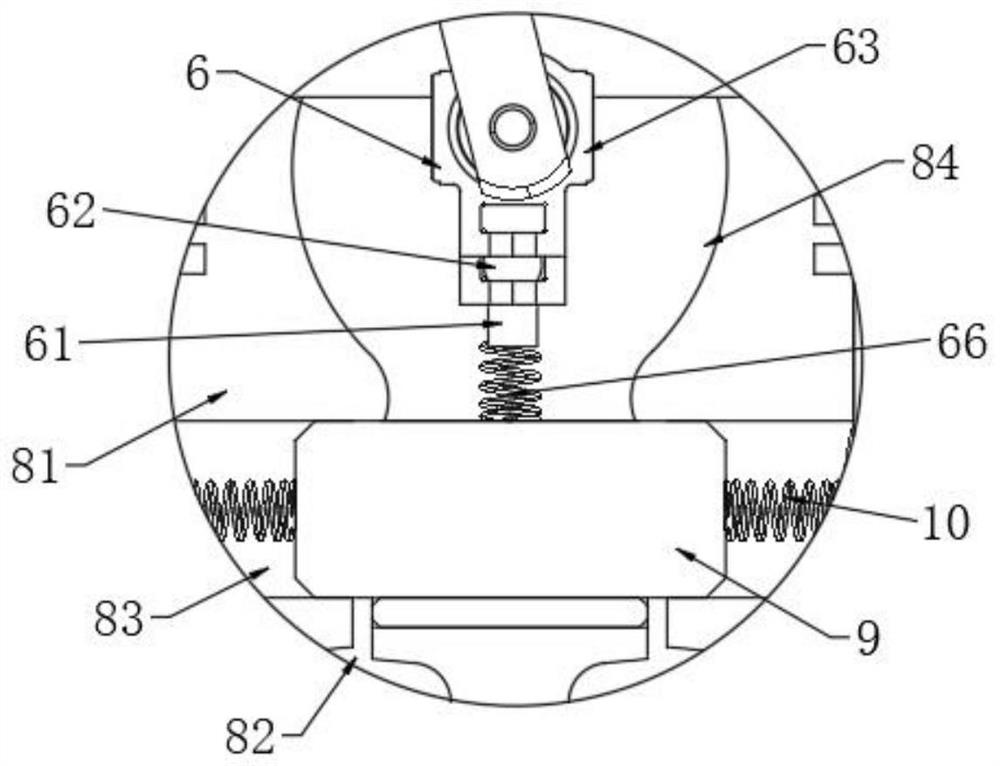

[0037] see Figure 1-6 , a linear reciprocating piston compressor, consisting of a first cylinder block 4, a piston 8, a rotating shaft 1, a crankshaft 11, a connecting rod 12, a first movable mechanism 6 and a second movable mechanism 7.

[0038]Wherein, the left side wall of the first cylinder block 4 is fixedly connected with a fixed column 3, and the fixed column 3 plays a role of supporting the rotating shaft 1, and the upper end of the first cylinder block 4 is fixedly connected with a second cylinder block 5, The inner wall of the second cylinder block 5 is smeared with lubricating oil, which not only reduces the friction between the piston 8 and the second cylinder block 5, but also reduces the noise. The upper end of the second cylinder block 5 is fixedly connected with a hollow casing 16. The inner cavity of the hollow casing 16 is used as the moving space of the second moving mechanism 7, and the inner cavities between the first cylinder block 4, the second cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com