High-voltage circuit breaker high-power spring operating mechanism

A high-voltage circuit breaker and operating mechanism technology, applied in the field of high-voltage power transmission and transformation, can solve the problems of difficult to meet product requirements of high-power operating work, poor mechanical stress matching of high-voltage circuit breakers, and limiting the use range of spring operating mechanisms. , to achieve the effects of stable mechanical characteristics, large opening and closing operation power, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

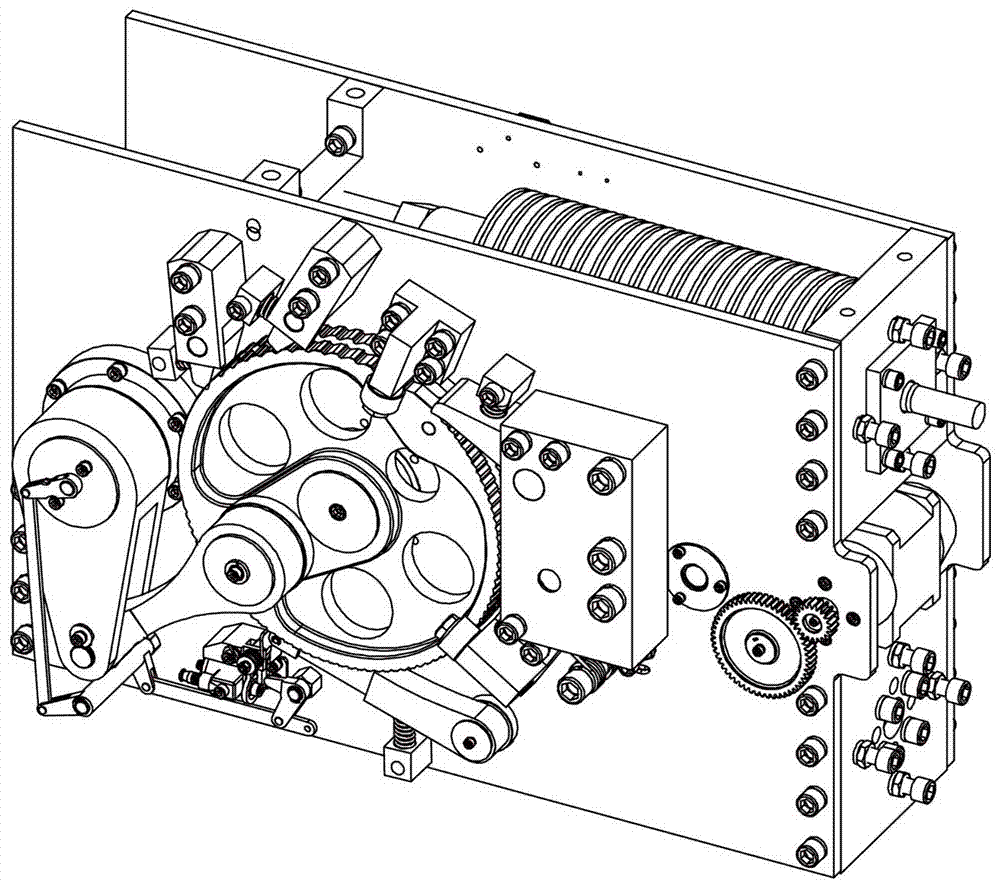

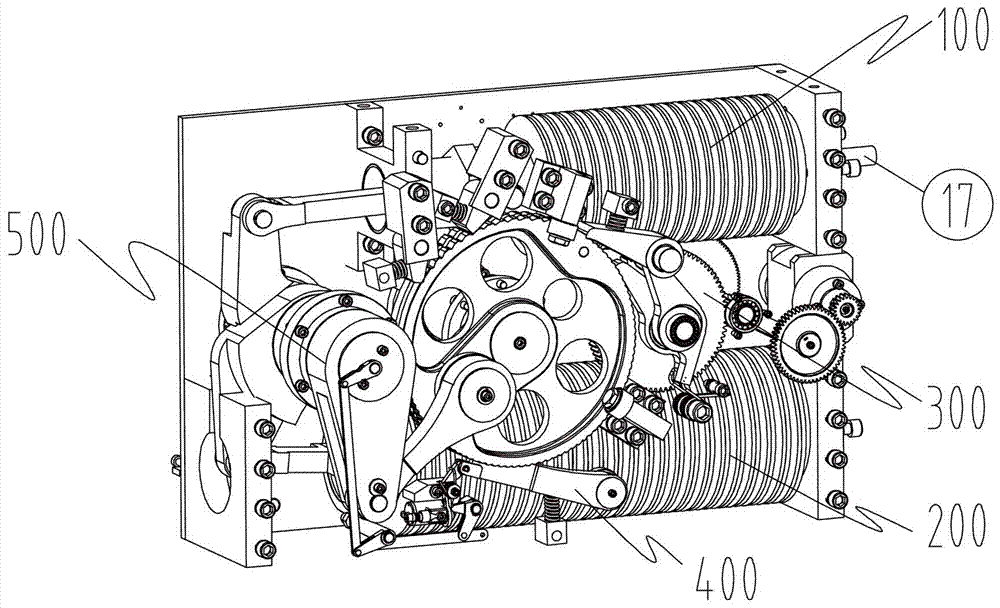

[0048] like Figure 1 to Figure 6 As shown, a high-power spring operating mechanism of a high-voltage circuit breaker is provided with an opening energy storage spring system 100 and a closing energy storage spring system 200 parallel up and down between the left wall plate 69 and the right wall plate 49, wherein the opening The energy storage spring system 100 is connected with the piston rod 17 for the opening and closing output action; the energy storage transmission system 300 is connected to the closing energy storage spring system 200 on the outer wall of the right wall plate 49 to provide energy storage operation, and on the outer wall of the left wall plate 69 The opening energy storage operation is provided by the curved surface sliding contact with the opening energy storage spring system 100. The ratchet shaft 26 of the energy storage transmission system 300 passes between the left wall plate 69 and the right wall plate 49; 49 is provided with a closing detent syste...

Embodiment 2

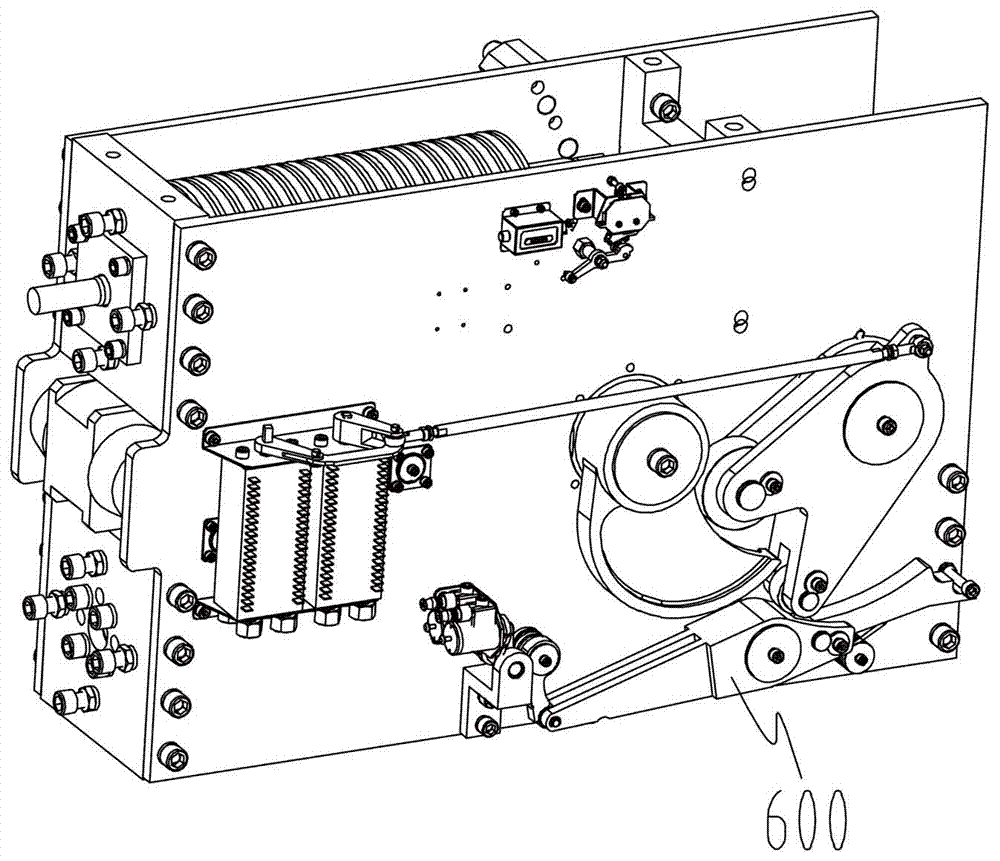

[0062] like Figure 16 to Figure 18 As shown, the structure of the energy storage transmission system 300 is that a motor 19, a ratchet shaft 26 and at least one crankshaft 50 are arranged between the left wall plate 69 and the right wall plate 49, one crankshaft 50 is a driving crankshaft, and the rest It is a driven crankshaft, and the driven crankshaft meshes with the transmission gear on the driving crankshaft through the gear 701. The driving crankshaft and the driven crankshaft form a double crankshaft structure at the same time; after the end of the ratchet shaft 26 stretches out from the right wall plate 49, it is the same as the ratchet 57. Shaft connection, ratchet shaft 26 coaxial linkage output shaft system 500; the outer circumference of the ratchet 57 has a groove, the peripheral surface has ratchet teeth, and the closing card roller 58 is arranged in the groove, and the closing card roller 58 is in the closing position. When the brake energy storage is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com