Natural gas pipeline sampling valve

A technology for natural gas pipelines and sampling valves, applied in sampling, sampling devices, valve details, etc., can solve problems such as dust accumulation on the surface of sampling valves on pipelines, air leakage, and air leakage at the connection port, so as to reduce the risk of external influence and ensure sampling Efficiency and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

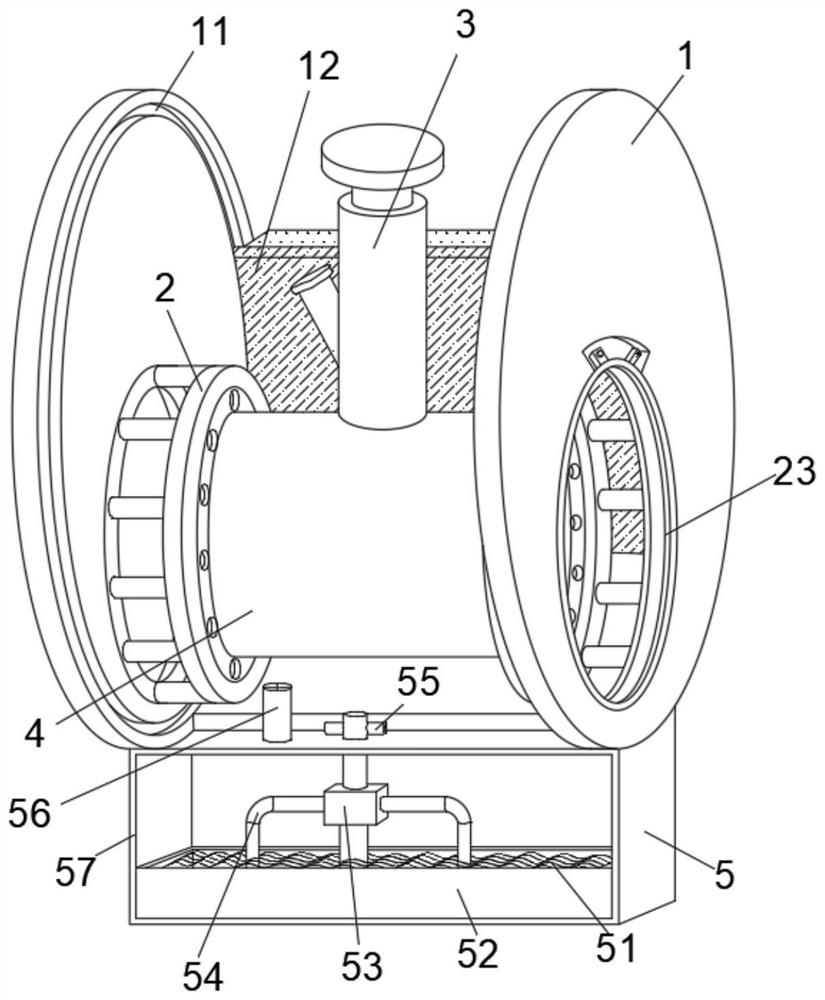

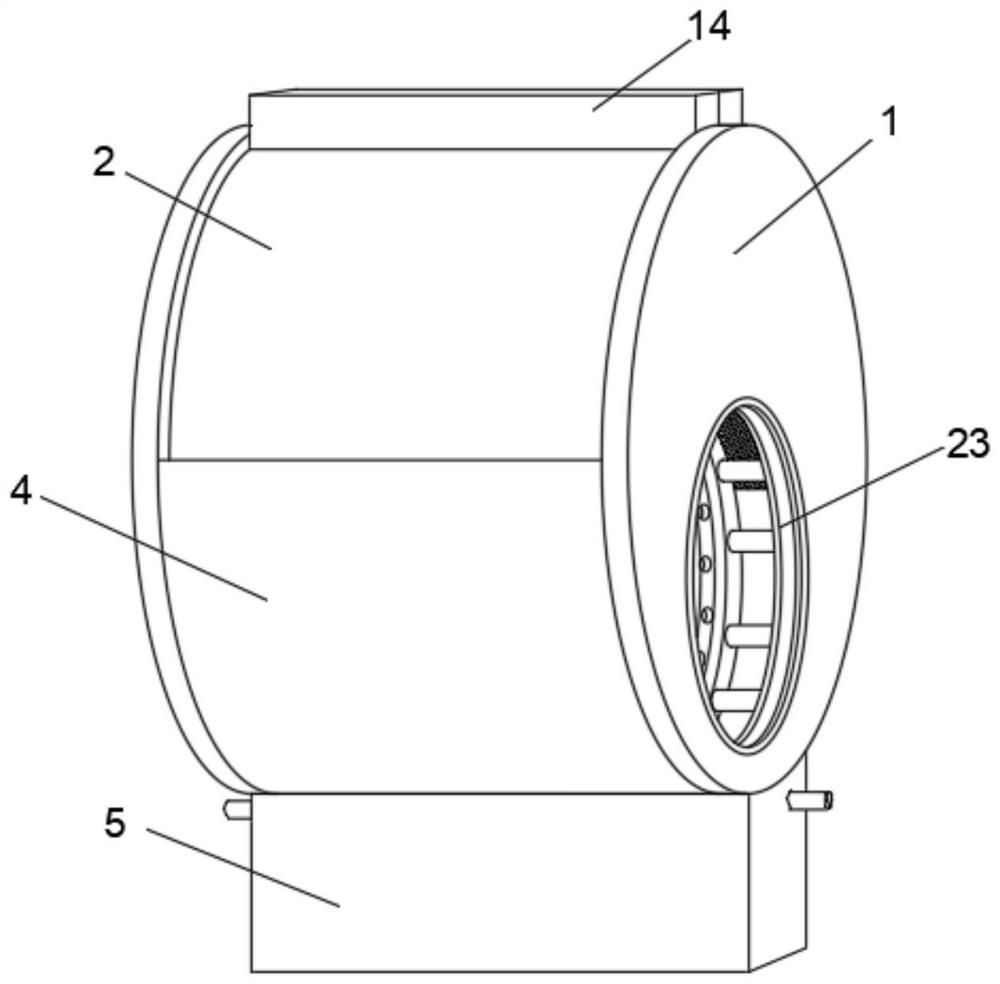

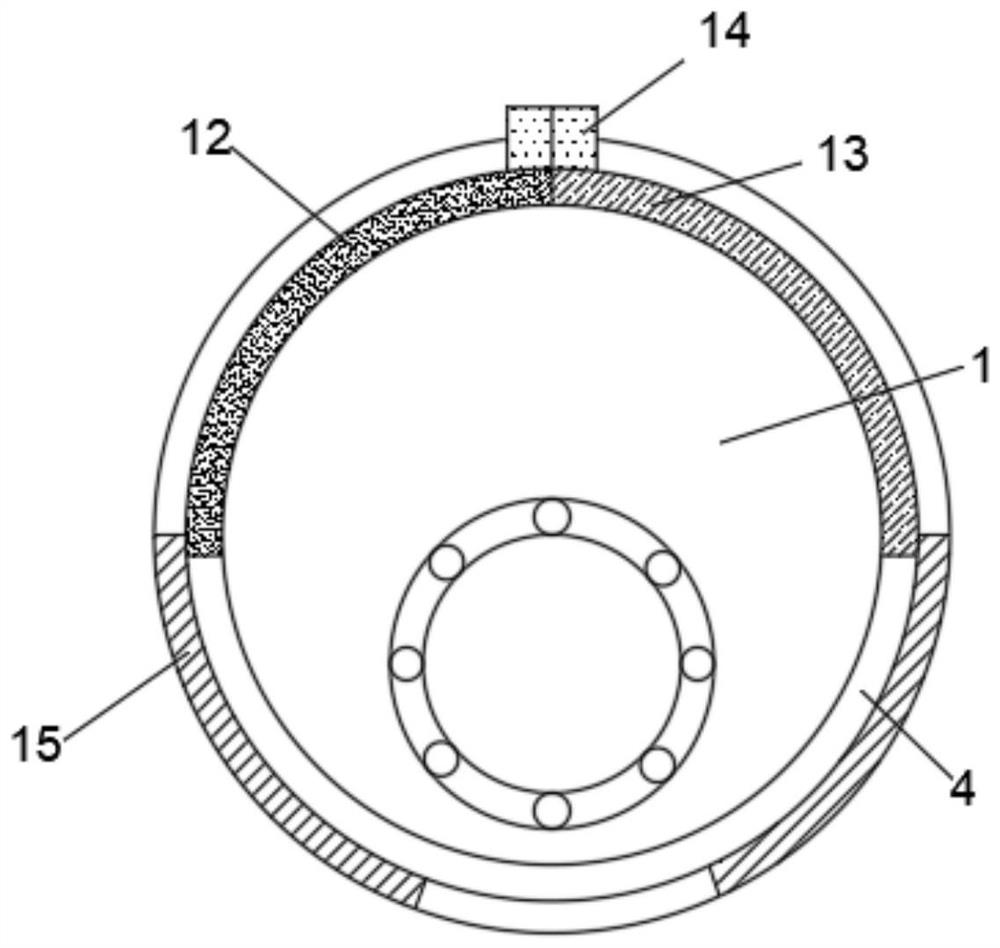

[0038] As an embodiment of the present invention, the inner surface of the fixing groove 23 is slidably connected with a clamp 231, and the outer surface of the baffle plate 1 is provided with a sliding groove 237 at a position above the fixing groove 23, and the sliding groove 237 is The lower end of the inner surface is provided with a slideway 236, the slideway 236 communicates with the fixed groove 23, the front end of the inner surface of the slideway 237 is provided with a slot 235, and the outer circular surface of the clamp 231 is fixedly connected with a gasket 232, The inner surface of the slideway 236 is slidably connected with a fixed block 233, the lower end of the fixed block 233 is fixedly connected with the clamp 231, and the outer surface of the front end of the fixed block 233 is provided with a fixed hole 234, and the fixed hole 234 has the same diameter as the slot 235, and the inner surface of the fixing hole 234 and the slot 235 is slidingly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com