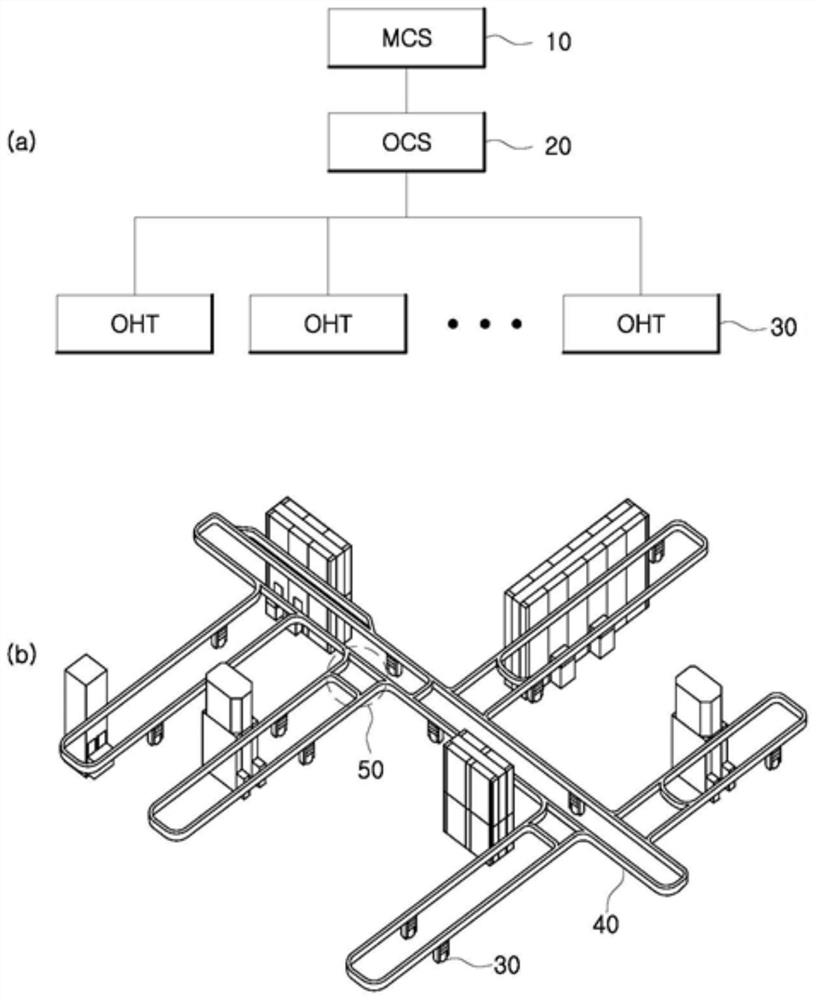

Method and device for controlling overhead hoist transfer vehicle

A vehicle control and vehicle technology, which is applied to conveyor control devices, vehicle position/route/height control, storage devices, etc., can solve problems such as impact on loads, and achieve the effect of solving malfunctions and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

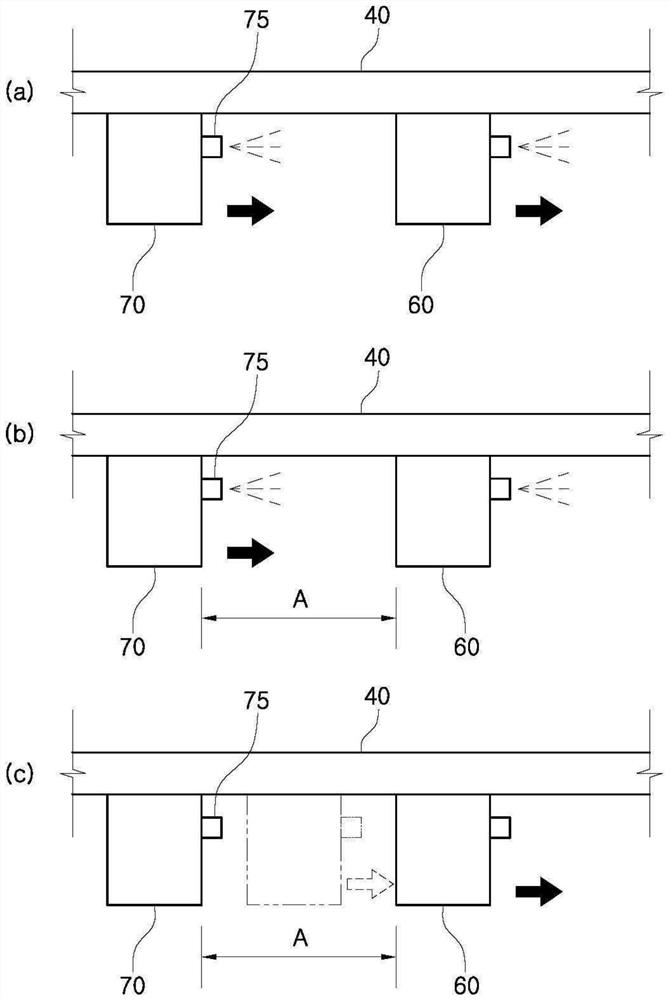

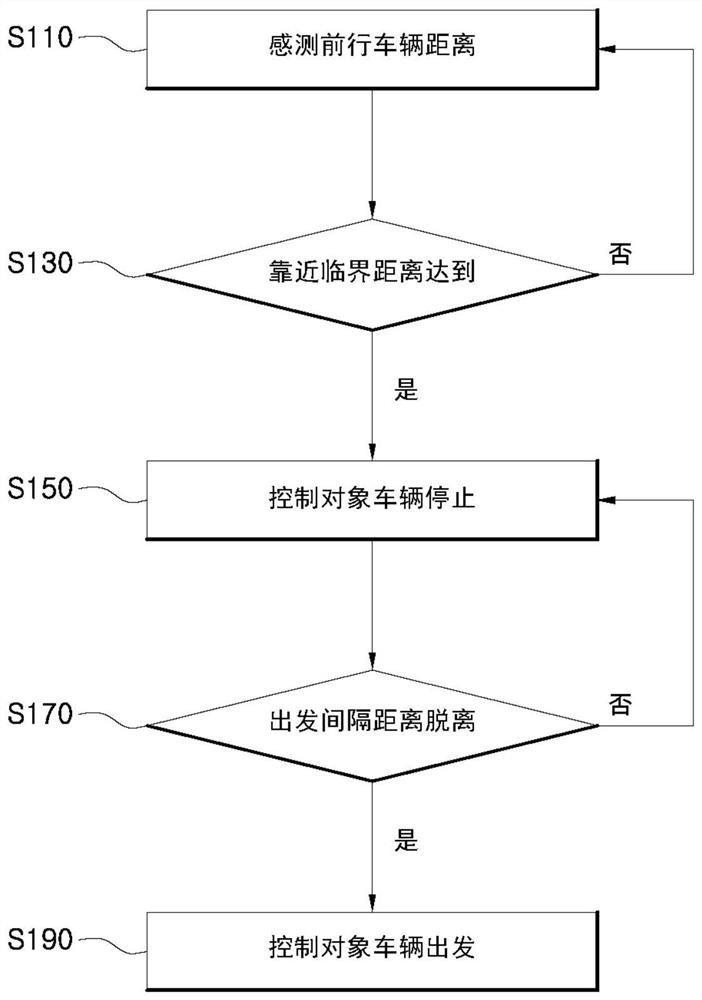

Embodiment Construction

[0058] In order to explain the present invention, its operational advantages, and objects achieved by implementing the present invention, preferred embodiments of the present invention will be illustrated below and described with reference to them.

[0059] First of all, the terms used in this application are only used to describe specific embodiments and are not used to limit the present invention. As long as different meanings are not clearly indicated in the context, singular expressions may include plural expressions. In addition, in this application, terms such as "comprising" or "having" are used to refer to the existence of features, numbers, steps, actions, constituent elements, parts or their combinations described in the specification, and it should be understood that they do not preclude a or the presence or additional possibility of other features above or numbers, steps, actions, constituent elements, parts, or combinations thereof.

[0060] In the description of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com