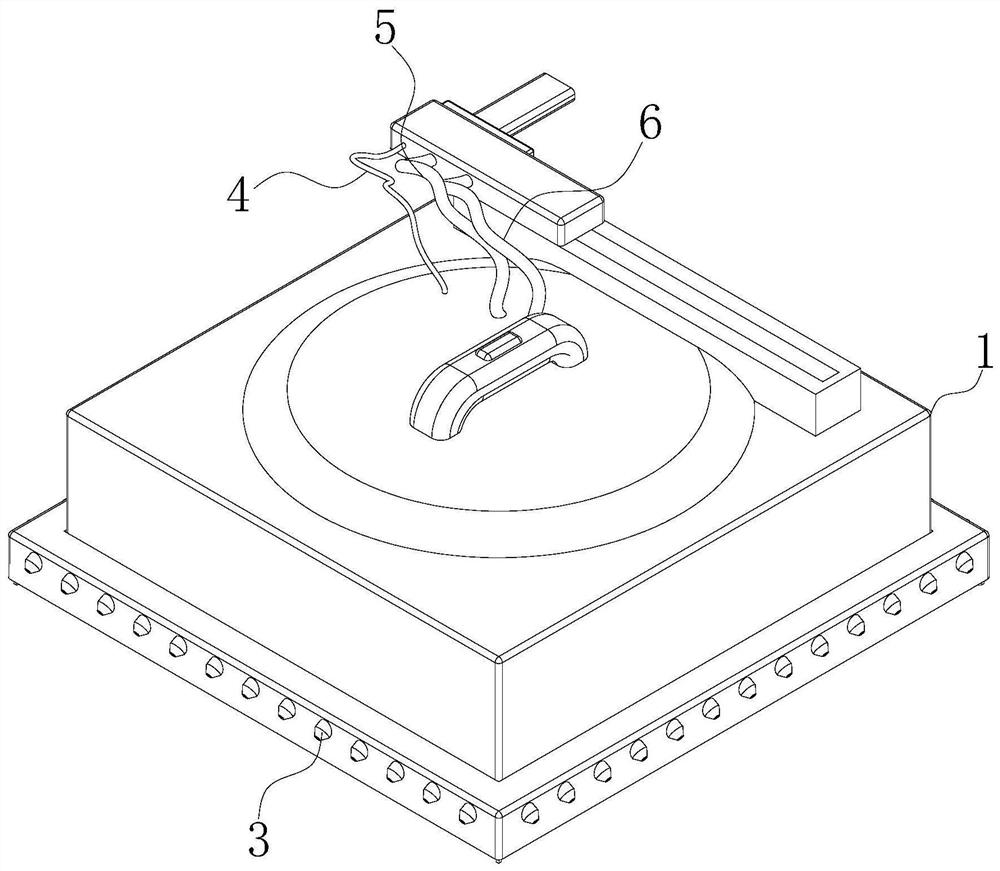

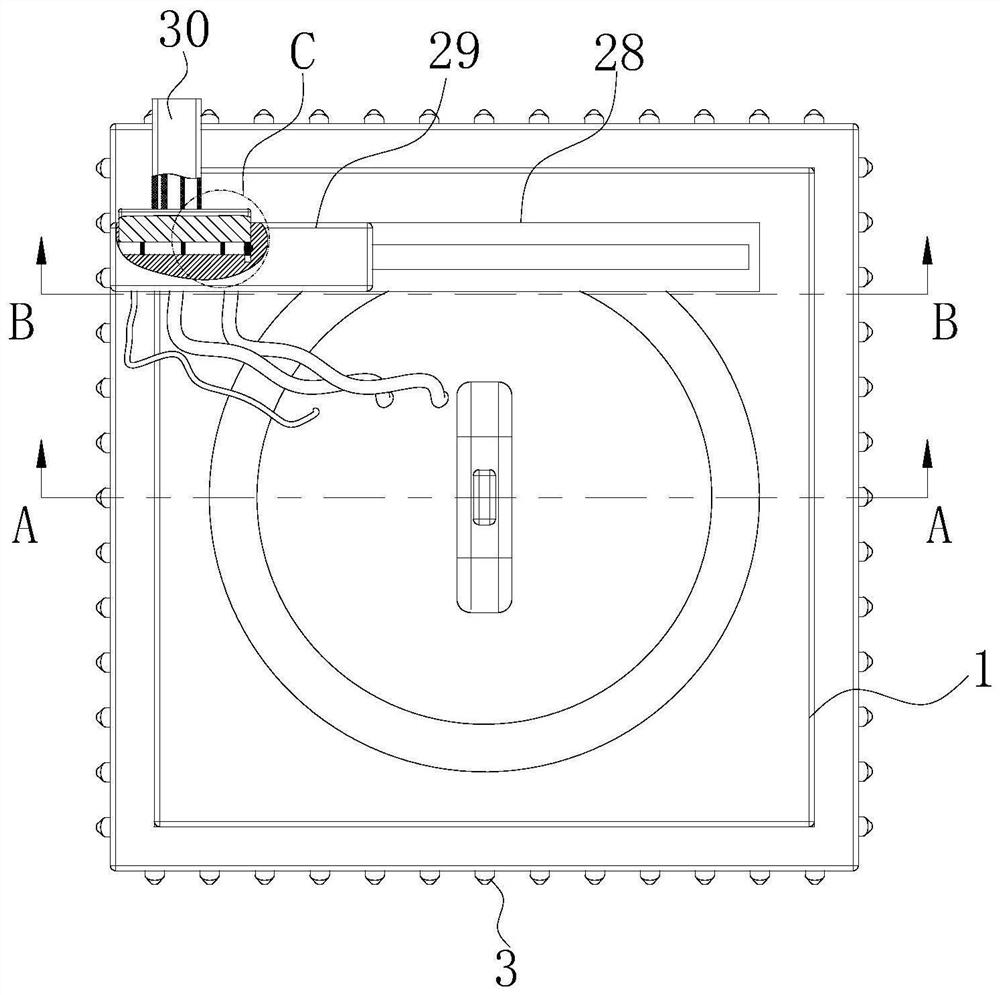

A building automatic glass cleaning robot

A glass cleaning, robotic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

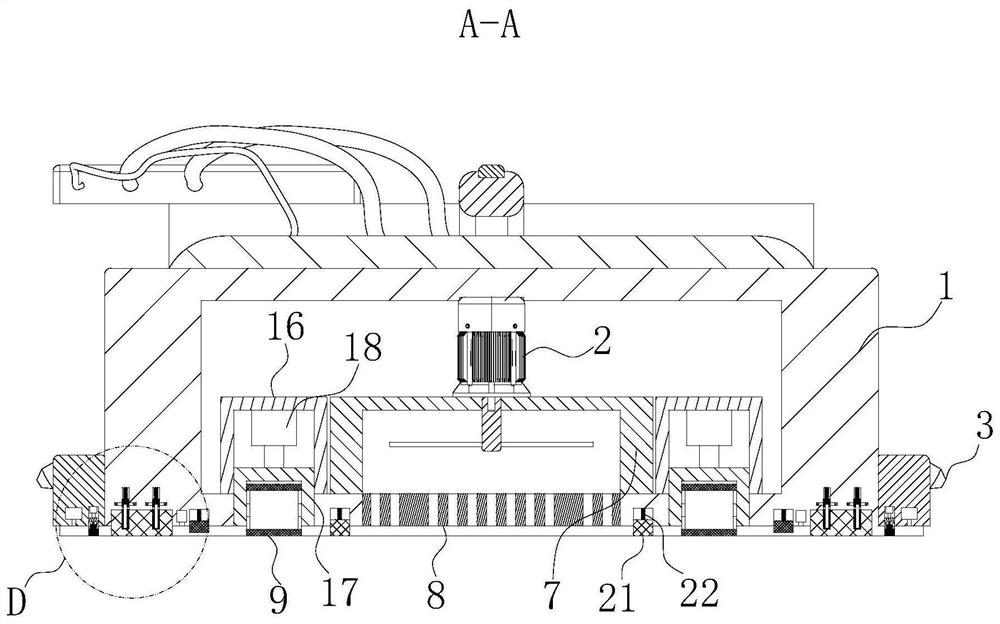

[0029] As an embodiment of the present invention, the lower surface of the housing 1 is provided with an adjustment slot; the inside of the adjustment slot is slidably connected with an adjustment plate 13; the side of the adjustment slot is fixed with evenly arranged first telescopic Rod 14; the lower surface of the housing 1 is provided with a chute at the position of the scraper 10; the inside of the chute is slidably connected to the scraper 10; the bottom of the chute is fixedly connected with a second telescopic rod 15 , and the second telescopic rod 15 communicates with the corresponding first telescopic rod 14; when working, by setting the adjusting disc 13, when the robot moves, the adjusting disc 13 will contact and rub against the glass, so that the adjusting disc 13 is in contact with the glass. The inside of the adjustment tank moves and squeezes the first telescopic rod 14 on the side of the adjustment tank that is away from the moving direction of the robot, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com