Constructional engineering dust falling device with wide spray coverage range

A technology of construction engineering and dust suppression device, which is applied in the direction of separation method, use of liquid separation agent, separation of dispersed particles, etc., and can solve the problems of flexible adjustment of areas that cannot be sprinkled, inability to spray, and limited adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

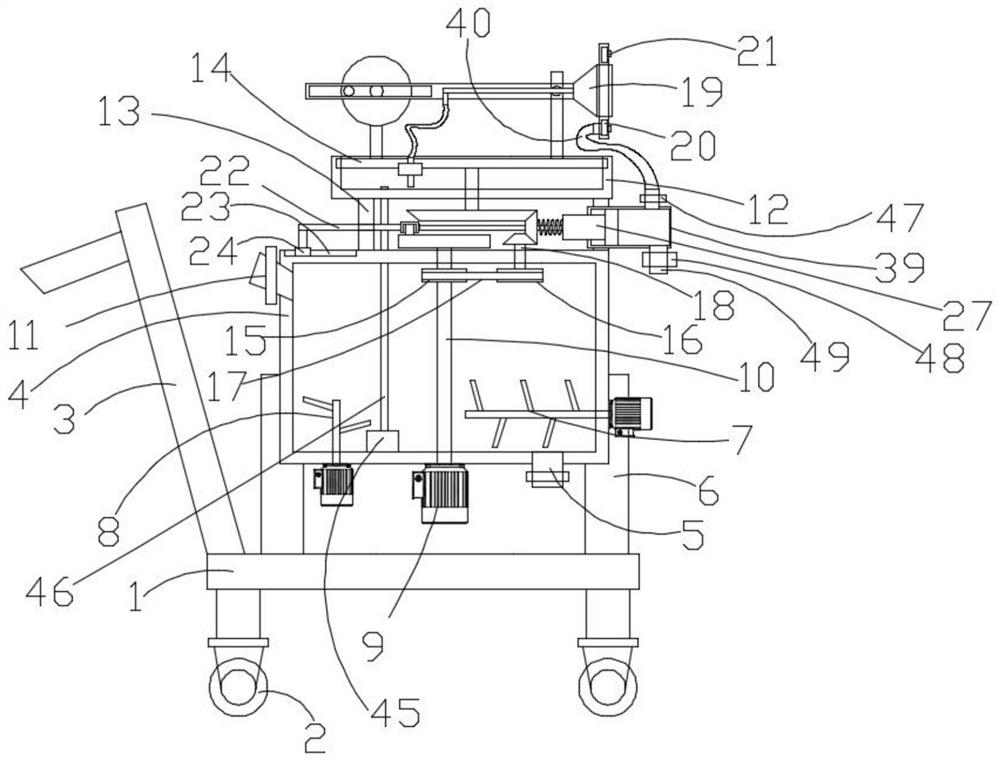

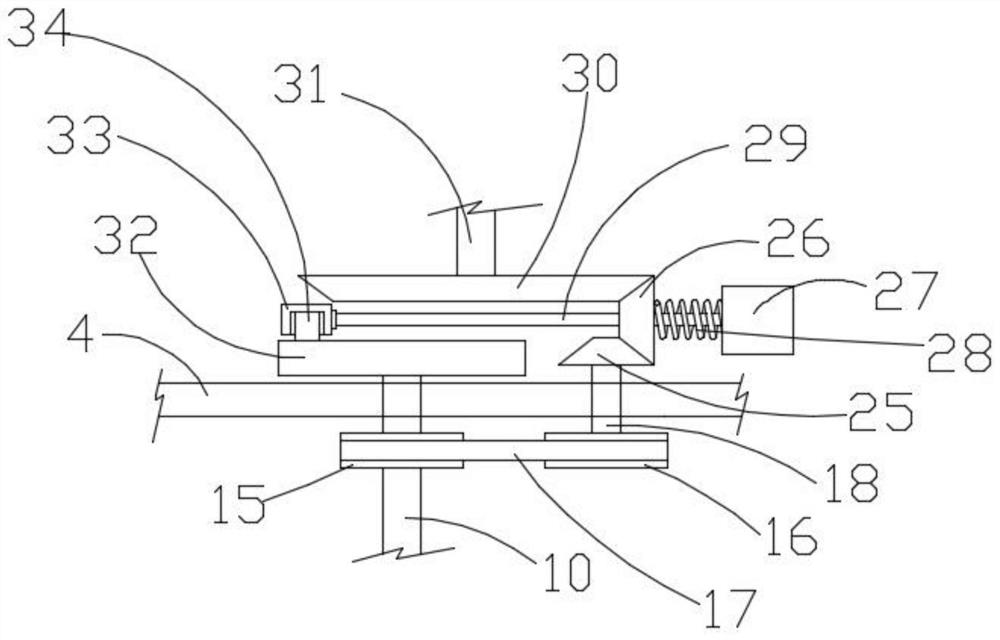

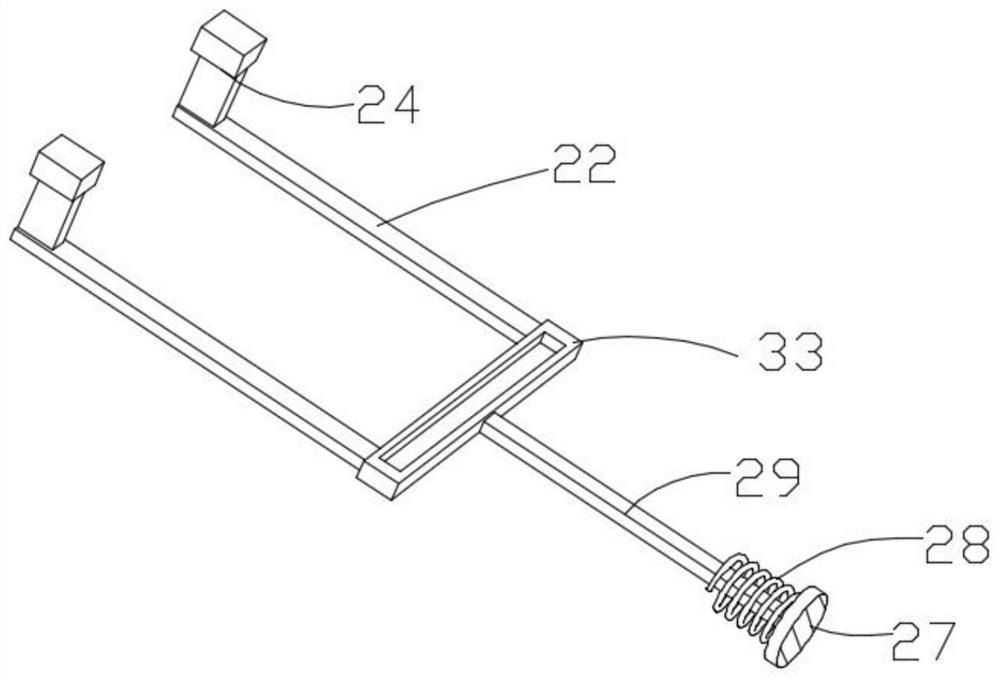

[0035] Such as Figure 1-2 As shown, in the embodiment of the present invention, a construction dust suppression device with a wide spray coverage includes a base 1, and a clean water tank 4 is fixedly installed on the base 1 through support legs 6, and the clean water tank 4 is internally rotated. There is a vertically placed first rotating shaft 10, a first motor 9 for driving the first rotating shaft 10 to rotate is installed on the bottom plate of the clean water tank 4, and a support rod 13 is provided above the top plate of the clean water tank 4 A support slot 12, on which a second rotating shaft 31 placed vertically is rotated, and the first rotating shaft 10 is connected with the second rotating shaft 31 through a linkage mechanism. When the first rotating shaft 10 rotates , which can drive the second rotating shaft 31 to rotate.

[0036] Further, in the preferred embodiment provided by the present invention, the top opening of the support groove 12 is sealed and rot...

Embodiment 2

[0040] Such as Figure 1-2 As shown, in the embodiment of the present invention, a construction dust suppression device with a wide spray coverage includes a base 1, and a clean water tank 4 is fixedly installed on the base 1 through support legs 6, and the clean water tank 4 is internally rotated. There is a vertically placed first rotating shaft 10, a first motor 9 for driving the first rotating shaft 10 to rotate is installed on the bottom plate of the clean water tank 4, and a support rod 13 is provided above the top plate of the clean water tank 4 A support slot 12, on which a second rotating shaft 31 placed vertically is rotated, and the first rotating shaft 10 is connected with the second rotating shaft 31 through a linkage mechanism. When the first rotating shaft 10 rotates , which can drive the second rotating shaft 31 to rotate.

[0041] Further, in the preferred embodiment provided by the present invention, the top opening of the support groove 12 is sealed and rot...

Embodiment 3

[0047] Such as Figure 1-2 As shown, in the embodiment of the present invention, a construction dust suppression device with a wide spray coverage includes a base 1, and a clean water tank 4 is fixedly installed on the base 1 through support legs 6, and the clean water tank 4 is internally rotated. There is a vertically placed first rotating shaft 10, a first motor 9 for driving the first rotating shaft 10 to rotate is installed on the bottom plate of the clean water tank 4, and a support rod 13 is provided above the top plate of the clean water tank 4 A support slot 12, on which a second rotating shaft 31 placed vertically is rotated, and the first rotating shaft 10 is connected with the second rotating shaft 31 through a linkage mechanism. When the first rotating shaft 10 rotates , which can drive the second rotating shaft 31 to rotate.

[0048] Further, in the preferred embodiment provided by the present invention, the top opening of the support groove 12 is sealed and rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com