Heat-conducting medium smearing device for laptop cooler copper sheet

A heat-conducting medium and heat sink technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of time-consuming, labor-intensive, low efficiency, etc., and achieve the effects of improving work efficiency, saving time, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A device for applying heat-conducting medium to copper sheets of a notebook radiator, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a blanking frame 2, a reciprocating mechanism 3 and a clamping mechanism 4. The left side of the top of the bottom plate 1 is connected with the blanking frame 2, and the right side of the top of the bottom plate 1 is connected with the reciprocating mechanism 3. The left and right sides of the top of the bottom plate 1 Both sides are connected with clamping mechanism 4.

[0033] The reciprocating mechanism 3 includes a support plate 30, a servo motor 31, a groove cylinder 32, a brush 33 and a first spring 34. The bottom plate 1 top right side is connected with a support plate 30, and the top of the support plate 30 is equipped with a servo motor 31, and the servo motor 31 outputs The shaft is connected with a grooved cylinder 32 , the other end of the grooved cylinder 32 is rotationally connected to the left side ...

Embodiment 2

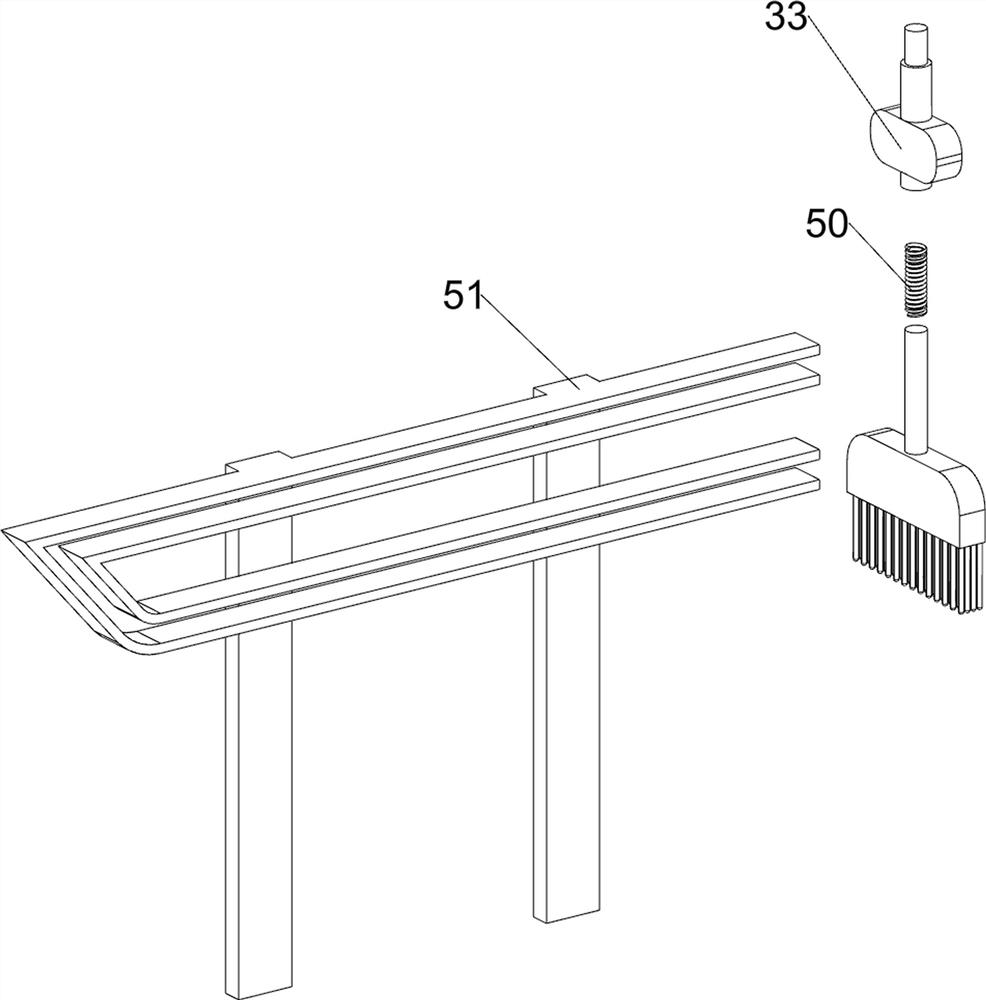

[0037] On the basis of Example 1, such as image 3 As shown, a lifting mechanism 5 is also included, and the lifting mechanism 5 includes a third spring 50 and a first slide rail 51. The brush 33 is internally provided with a third spring 50, and the rear side of the bottom plate 1 is connected with a first slide rail 51. A sliding rail 51 cooperates with the brush 33 in a sliding manner.

[0038] When the brush 33 moved to the left and the first spring 34 was stretched, when the brush 33 moved to a certain position to the left, it moved upward under the action of the first slide rail 51, and the brush 33 moved upward and acted on the stretched first spring 34. When the brush 33 moves upwards, the copper sheet can be manually flanged, so there is no need to wait for the brush 33 to complete the reset before flanging, which saves time and improves work efficiency.

Embodiment 3

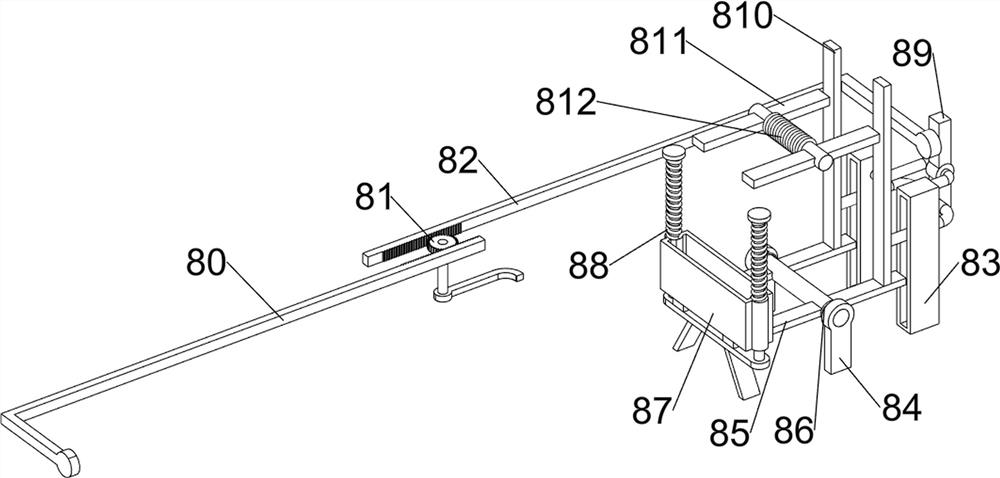

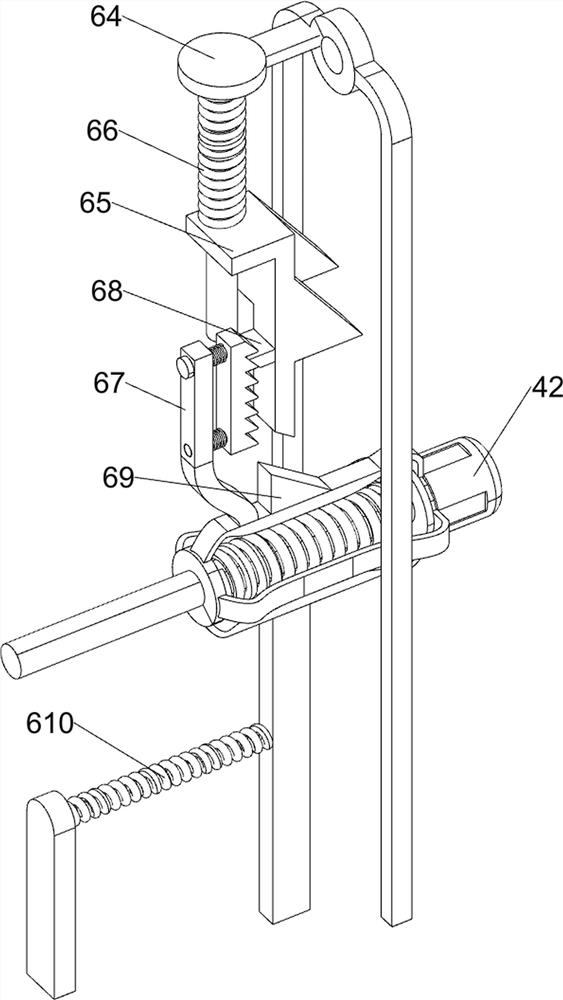

[0040] On the basis of Example 2, such as Figure 4 and Figure 5As shown, the elastic mechanism 6 is also included, and the elastic mechanism 6 includes a first push rod 60, a second push rod 61, a rotating rod 62, a first one-way torsion spring 63, a first fixed block 64, a wedge plate 65, a first Four springs 66, ratchet 67, block 68, first wedge-shaped block 69 and fifth spring 610, the left side of the front part of the brush 33 is connected with the first push rod 60, and the left side of the rear part of the brush 33 is connected with the second push rod 61 The left side of the second push rod 61 is rotatably connected with a rotating rod 62 , a first one-way torsion spring 63 is connected between the rotating rod 62 and the second push rod 61 , and a first fixed block 64 is connected on the left side of the top of the bottom plate 1 , The middle part of the first fixed block 64 is slidably connected with a wedge plate 65, and the wedge plate 65 cooperates with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com