Welding device convenient to use and using method thereof

A welding device and a convenient technology, applied in auxiliary devices, separation methods, welding equipment and other directions, can solve the problems of inconvenient fixing and clamping of pipe fittings, and the use scene affects welding operations, etc., to facilitate welding operations, facilitate welding accuracy, and expand the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

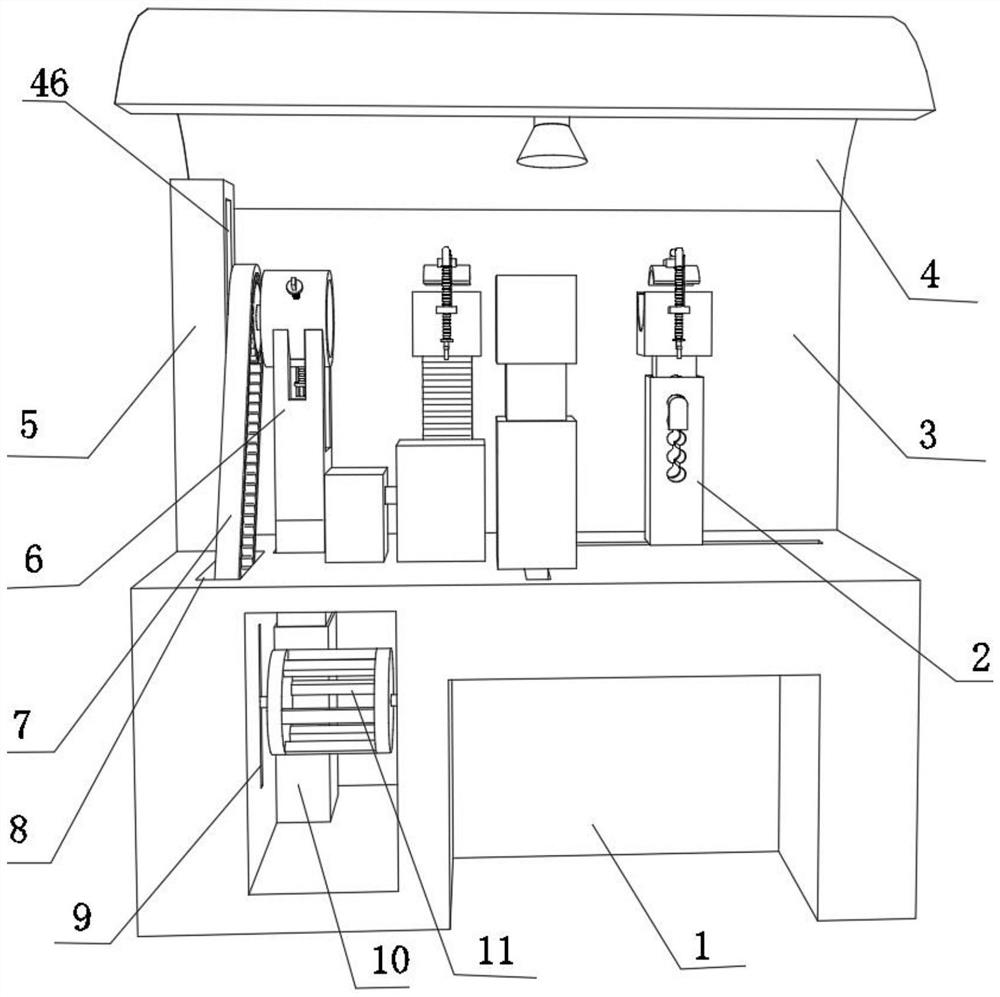

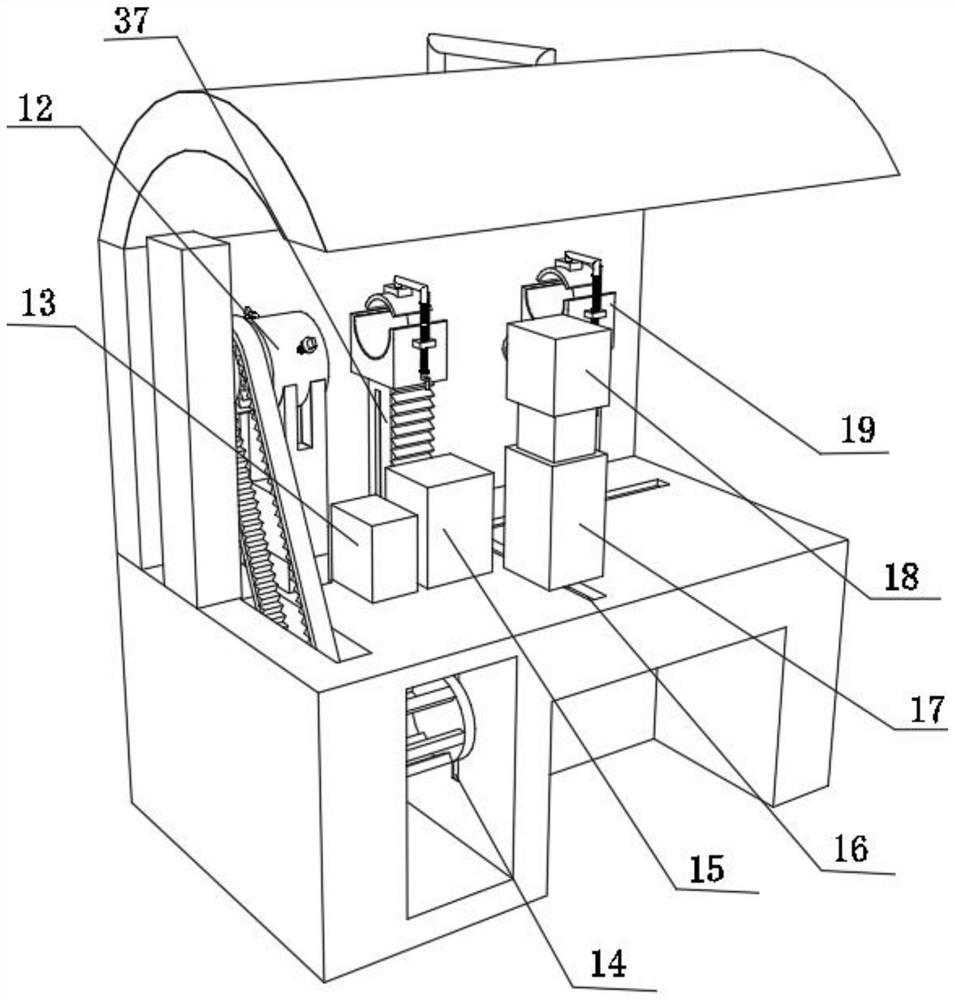

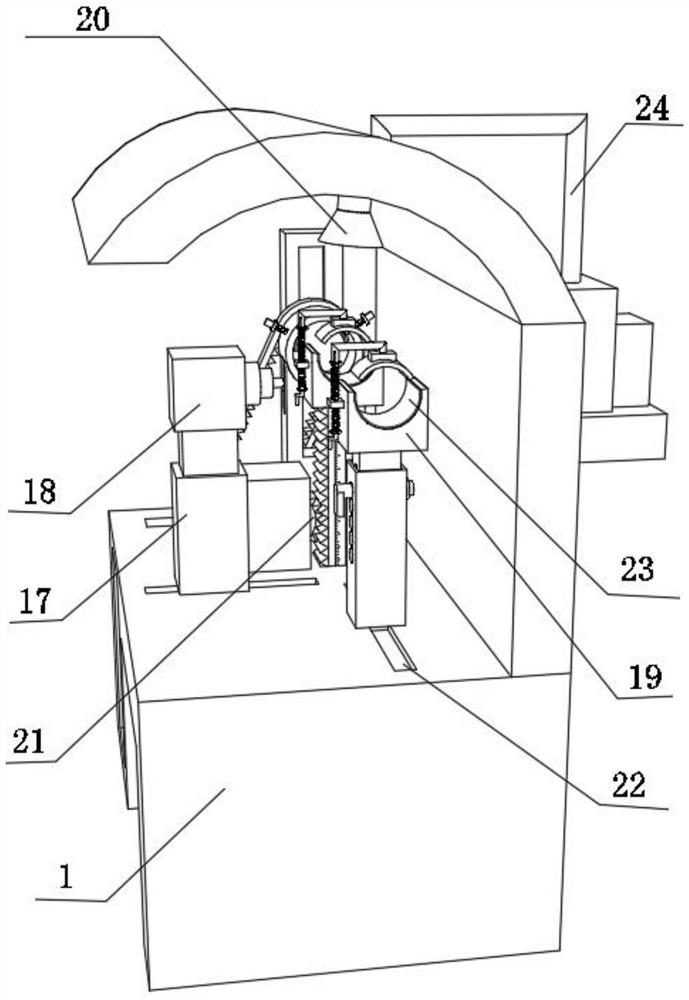

[0042] An easy-to-use welding device such as Figure 1-3 , Figure 5 , Figure 6 and Figure 8 As shown, including the body 1, the top outer wall of the body 1 is provided with a groove 29, and the inner wall on the opposite side of the groove 29 is fixed with a block 28 by bolts, and the inner walls of the two blocks 28 pass through the third chute respectively. 39 is slidably connected with the same elevating rod 37, and one side outer wall of the two third chute 39 is opened on the two side outer walls of elevating rod 37 respectively; The first lifting column 2 is slidably connected with the slider. The first lifting column 2 is a hollow structure. The outer walls of both sides of the first lifting column 2 are provided with first adjustment holes 33. The inner wall of the first lifting column 2 is inserted with a second Two lifting columns 30, and the top outer wall of the second lifting column 30 and the top outer wall of the lifting rod 37 are all fixed with a placem...

Embodiment 2

[0049] A method for using the easy-to-use welding device described in Embodiment 1, such as figure 1 shown, including the following steps:

[0050] S1: Adjust the height of the first lifting column 2 and the second lifting column 30, adjust the height of the lifting rod 37, so that the horizontal positions of the two placing seats 19 are equal;

[0051] S2: Manually adjust the distance between the pressure plate 40 and the placement seat 19, place the workpiece to the placement seat 19, adjust the pressure plate 40 to fix and clamp the workpiece;

[0052] S3: adjust the welding distance of the two welding workpieces through the sliding rail 22, and then adjust the front and rear distances of the welding assembly 18 through the moving rail 16 to perform welding;

[0053] S4: Start the exhaust fan 25 to collect the gas generated during welding and filter it out through the filter plate 27;

[0054]S5: Adjust the height of the clamping cylinder 12 to be equal to the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com