A kind of polyurethane resin and its preparation method and application

A polyurethane resin and urethane technology, applied in the field of polyurethane resin, can solve the problems of reducing the physical properties of materials, deterioration of wear and scratch resistance, poor weather resistance, etc., and achieves good weather resistance, good wear and scratch resistance, and water resistance. good solution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

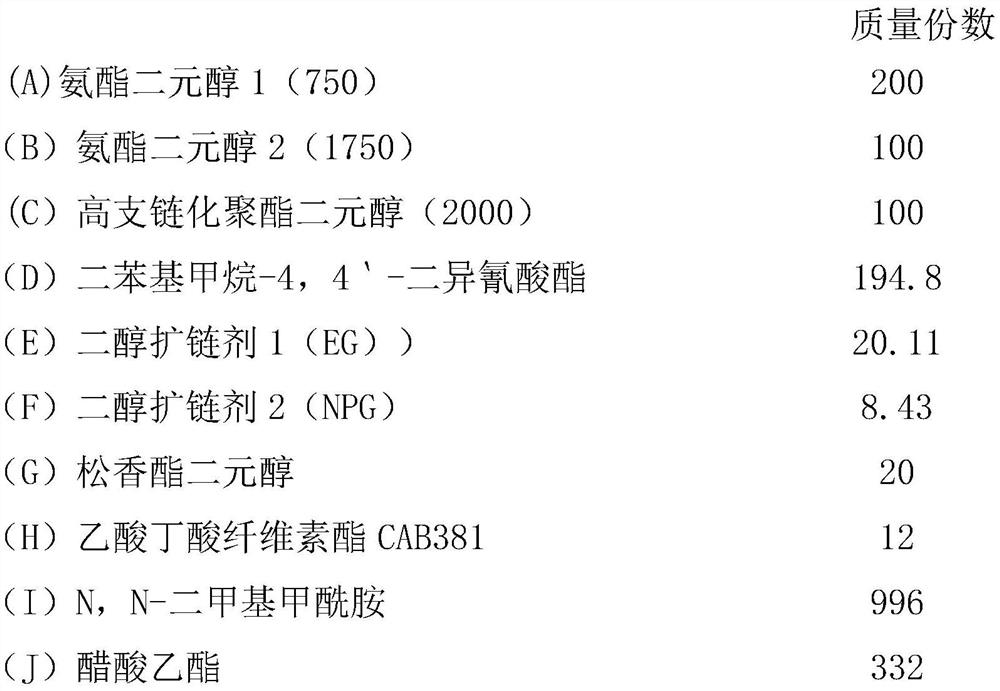

Embodiment 1

[0071]

[0072] (A) The preparation method of urethane diol 1:

[0073] The polyoxyethylene ether diol that the number average molecular weight of dropping into 1mol is 250g / mol in the reactor, the number average molecular weight of 1mol is the polytetrahydrofuran diol of 250g / mol, and 187.5 grams of N,N-dimethylformamide, Start stirring, control the reaction temperature at 50°C-60°C, after 1 hour, add 1mol of diphenylmethane-4,4‵-diisocyanate, control the reaction temperature at 70°C-80°C for 2 hours to obtain urethane Diol 1 with a number average molecular weight of 750 g / mol.

[0074] (B) The preparation method of urethane diol 2:

[0075] 1 mole of polycaprolactone diol with a number average molecular weight of 1000 g / mol, 1 mole of polytetrahydrofuran diol with a number average molecular weight of 500 g / mol, and 437.5 grams of N,N-dimethylformaldehyde in the reactor Amide, start stirring, control the reaction temperature at 50°C-60°C, after 1 hour, add 1mol of diphen...

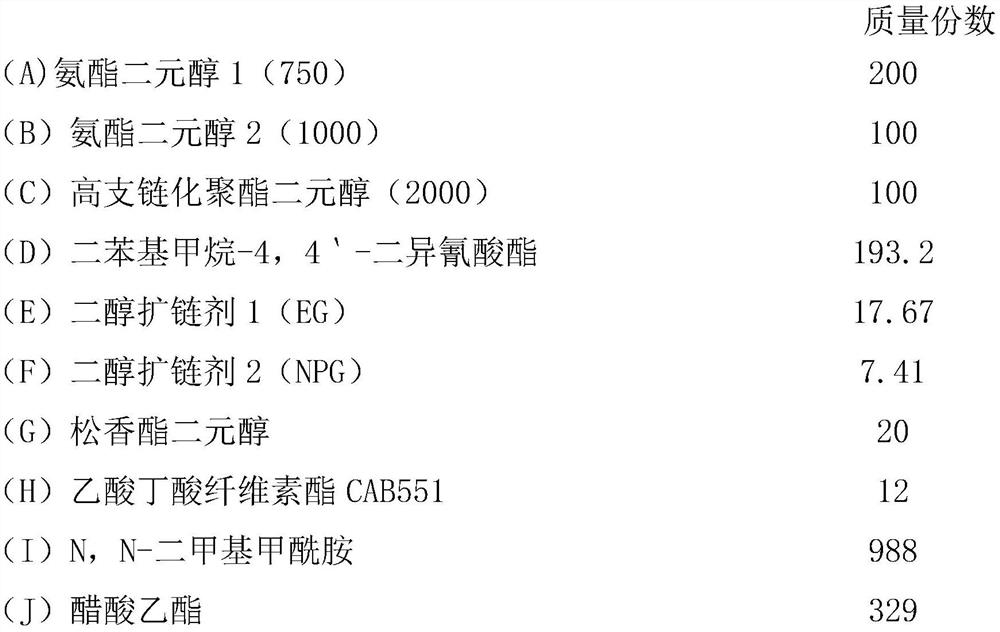

Embodiment 2

[0081]

[0082] (A) The preparation method of urethane diol 1:

[0083] The polyoxyethylene ether diol that the number average molecular weight of dropping into 1mol is 250g / mol in the reactor, the number average molecular weight of 1mol is the polytetrahydrofuran diol of 250g / mol, and 187.5 grams of N,N-dimethylformamide, Start stirring, control the reaction temperature at 50°C-60°C, after 1 hour, add 1mol of diphenylmethane-4,4‵-diisocyanate, control the reaction temperature at 70°C-80°C for 2 hours to obtain urethane Diol 1 with a number average molecular weight of 750 g / mol.

[0084] (B) The preparation method of urethane diol 2:

[0085] 1 mole of number average molecular weight is 500g / mol polycaprolactone diol, 1 mole of number average molecular weight is 250g / mol polytetrahydrofuran diol, and 250 grams of N,N-dimethylformaldehyde in the reactor Amide, start stirring, control the reaction temperature at 50°C-60°C, after 1 hour, add 1mol of diphenylmethane-4,4‵-diis...

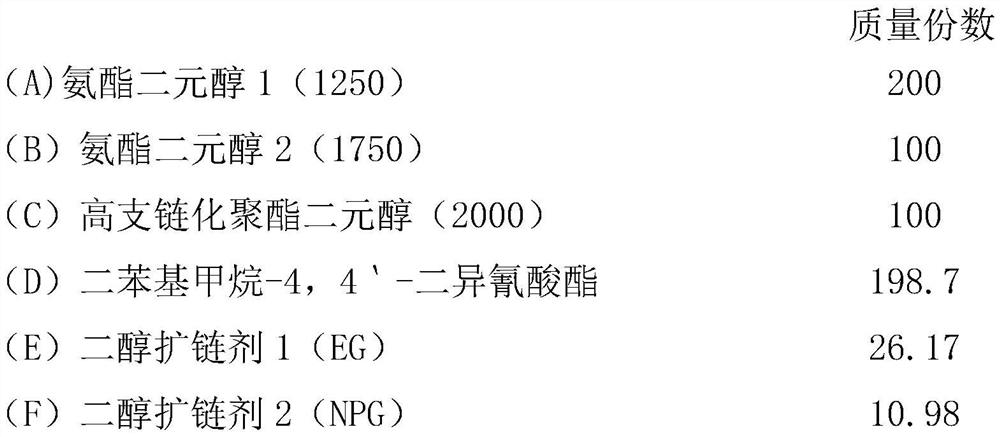

Embodiment 3

[0091]

[0092]

[0093](A) The preparation method of urethane diol 1:

[0094] The polyoxyethylene ether diol that the number average molecular weight of dropping into 1mol is 500g / mol in the reactor, the number average molecular weight of 1mol is the polytetrahydrofuran diol of 500g / mol, and 312.5 grams of N,N-dimethylformamide, Start stirring, control the reaction temperature at 50°C-60°C, after 1 hour, add 1mol of diphenylmethane-4,4‵-diisocyanate, control the reaction temperature at 70°C-80°C for 2 hours to obtain urethane Diol 1 with a number average molecular weight of 1250 g / mol.

[0095] (B) The preparation method of urethane diol 2:

[0096] 1 mole of polycaprolactone diol with a number average molecular weight of 1000 g / mol, 1 mole of polytetrahydrofuran diol with a number average molecular weight of 500 g / mol, and 437.5 grams of N,N-dimethylformaldehyde in the reactor Amide, start stirring, control the reaction temperature at 50°C-60°C, after 1 hour, add 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com