Telescopic sealing type rotary distributor and distributing method thereof

A divider and sealing technology, which is applied in the conveyor control device, loading/unloading, chute, etc., can solve the problems of polluting the surrounding environment, poor contact sealing between the rotating chute and the discharge port, etc. Manufactures the effect of inaccurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

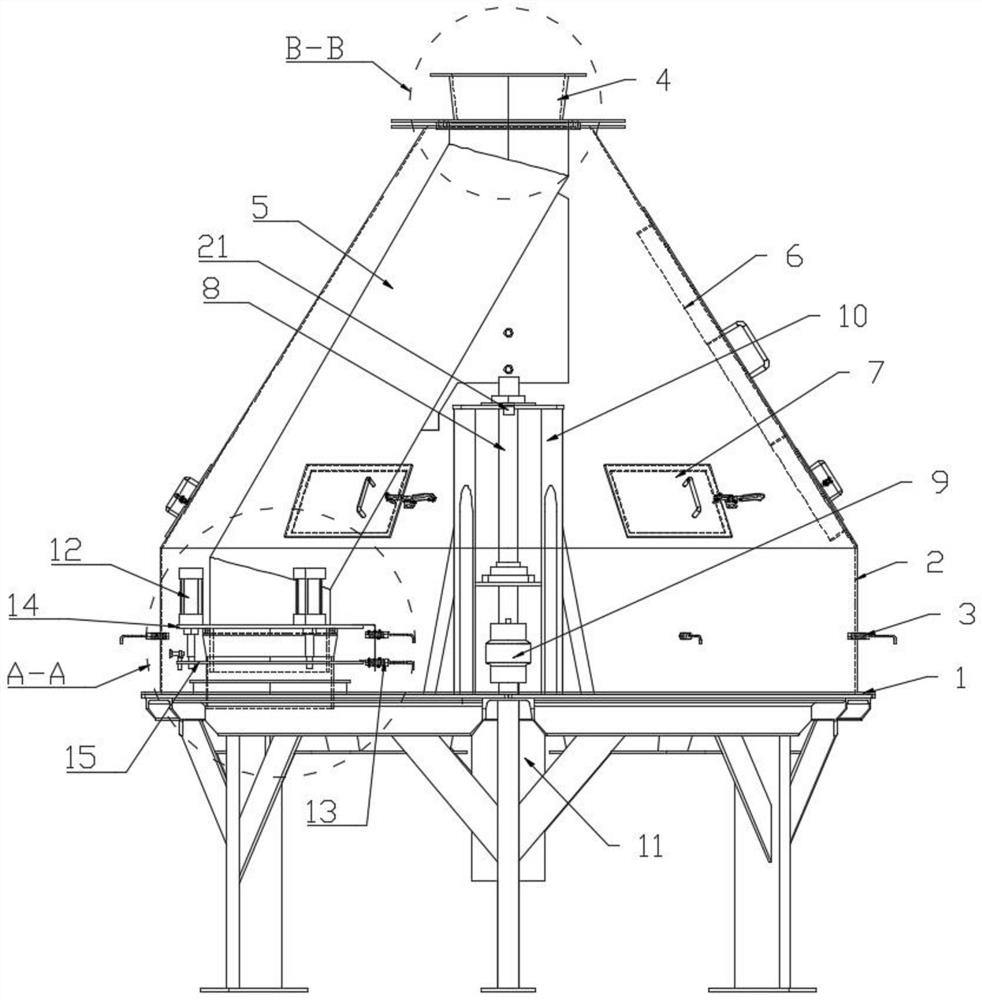

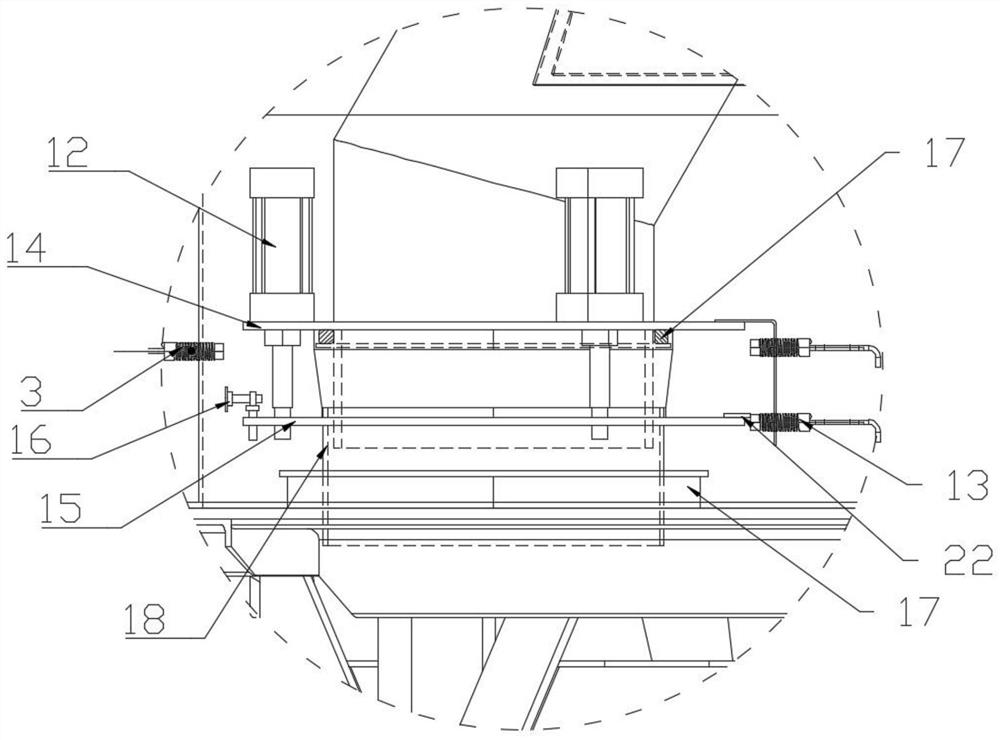

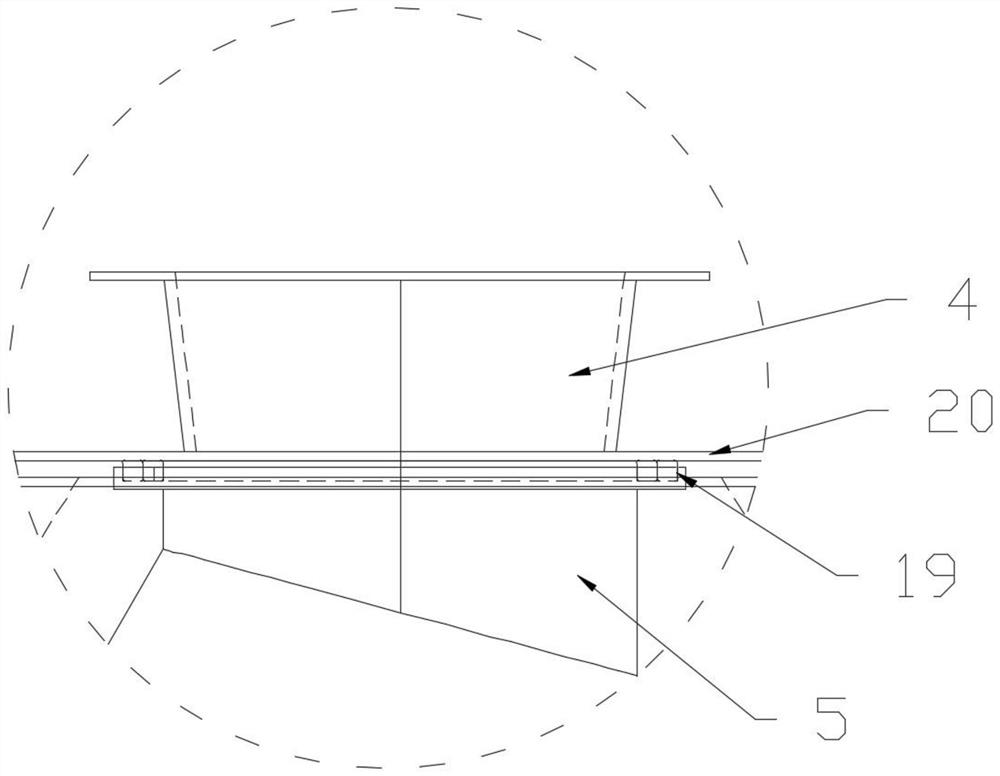

[0029] Such as Figure 1-4 As shown, according to an embodiment of the telescopic sealed rotary feeder provided by the present invention, it includes a bottom plate 1 and a sealing cover 2, the sealing cover 2 is fixed on the bottom plate 1, and the top of the sealing cover 2 is provided with a feeding The bucket 4 also includes a rotating chute 5. The bottom plate 1 is provided with a plurality of outlets distributed in a circular array at equal intervals. The rotating chute 5 is located in the sealing cover 2 and is rotatably connected to it. The feed hopper 4 communicate with one of the outlets through the rotating chute 5, the bottom of the rotating chute 5 is connected to the telescopic chute 18, and at least two cylinders 12 are fixed at the bottom of the outer wall of the rotating chute 5, and the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com