Anti-breakage and anti-loosening rope protection device for elevator

A protection device and anti-fracture technology, which is applied in hoisting devices, elevators in buildings, transportation and packaging, etc., can solve problems affecting the normal use of elevators and breakage of traction ropes, so as to prevent breakage and reduce mechanical stress. Dynamic loss, reduce the effect of rigid braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

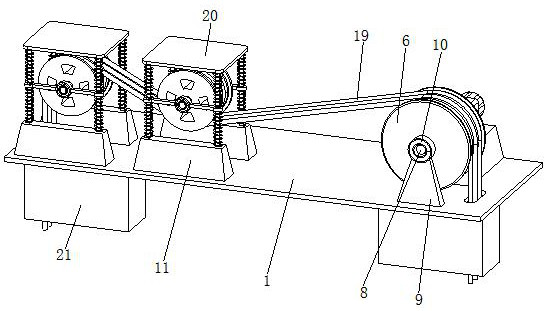

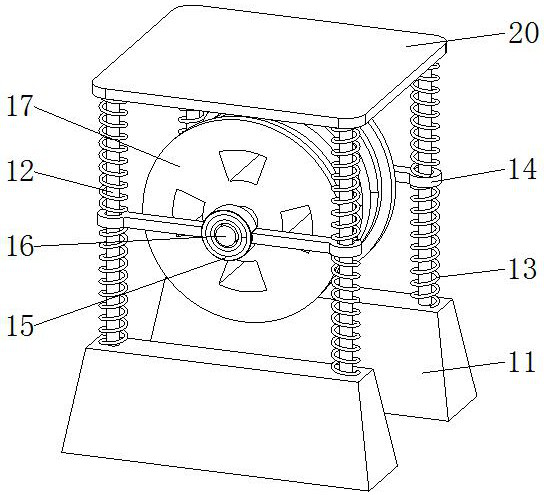

[0026] see Figure 1-6 , the present invention provides a technical solution: an anti-breakage and anti-loosening rope protection device for an elevator, comprising a base plate 1, a fixed base 11 is fixedly installed on the top of the base plate 1, a fixed rod 12 is fixedly installed on the top of the fixed base 11, and the fixed rod The outer movable socket of 12 is provided with a position spring 13, the external movable socket of the fixed rod 12 is provided with a socket rod 14, the inside of the socket rod 14 is fixedly installed with a socket bearing 15, and the inside of the socket bearing 15 is fixedly installed with a guide Rod 16, one side of the guide rod 16 is fixedly equipped with a guide wheel 17, the outside of the guide wheel 17 is provided with a guide groove 18, the inside of the guide groove 18 is equipped with a traction rope 19, and the bottom of the bottom plate 1 is fixedly installed with a brake box 21. The top and bottom of the bottom plate 1 are prov...

Embodiment 2

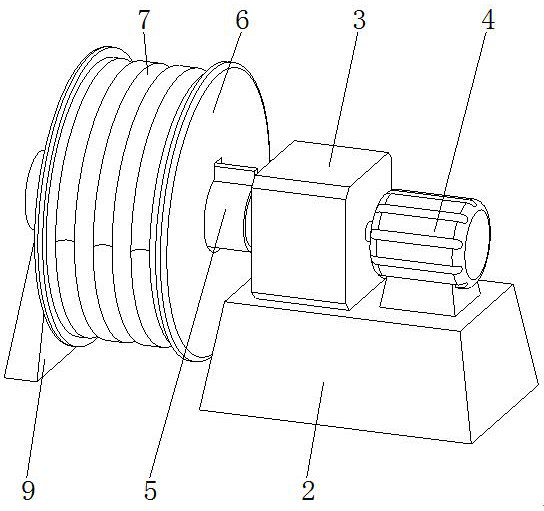

[0029] like Figure 1-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top of the bottom plate 1 is fixedly installed with a mounting base 2, the top of the mounting base 2 is fixedly mounted with a reducer 3, and the top of the mounting base 2 is fixed A rotating motor 4 is installed, and the output end of the rotating motor 4 runs through the reducer 3 and extends to its interior. The side of the reducer 3 far away from the rotating motor 4 is movably installed with a rotating rod 5 , and the outer part of the rotating rod 5 is movably sleeved with a traction The pulley 6 and the outside of the traction wheel 6 are provided with a traction groove 7, and the side of the traction wheel 6 away from the rotating rod 5 is fixedly installed with a rotating rod 8, and the top of the bottom plate 1 is fixedly installed with a support frame 9, and the top of the support frame 9 The rolling bearing 10 is fixedly installed, and the end o...

Embodiment 3

[0032] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: there are four fixed bases 11, and the four fixed bases 11 are divided into two groups and symmetrically installed on the top of the bottom plate 1 , there are four fixed rods 12, the four fixed rods 12 are rectangular and fixedly installed on the top of a group of fixed bases 11, the top of the four fixed rods 12 is fixedly installed with a top plate 20, there are two suitable springs 13, two suitable The position springs 13 are respectively positioned above and below the socket rod 14, and the front and rear sides of the guide wheel 17 are fixedly equipped with a guide rod 16, and the end of the guide rod 16 away from the guide wheel 17 runs through the sleeve bearing 15 and is fixedly installed inside it. , there are two guide wheels 17, multiple traction ropes 19, multiple traction ropes 19 are movably installed above the traction groove 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com