A kind of underwater quenching method of thin steel plate

A thin steel plate, laser quenching technology, applied in the direction of furnace, furnace type, heat treatment equipment, etc., can solve the problem of limited heat transfer effect of water on the matrix, and achieve the effect of reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The base material used for underwater laser quenching is 45# steel, which is machined into a metal sample of 100 × 50 × 3 mm, and the surface is cleaned with anhydrous ethanol solution after degreasing, rust removal, and polishing. Two brackets were placed at the bottom of the water tank as supports, and the metal samples were placed on the brackets to avoid direct contact between the metal samples and the bottom of the water tank. By adding an appropriate amount of deionized water into the water tank, the upper surface of the metal sample has a certain thickness of the water layer.

[0025] In this embodiment, the thickness of the water layer is controlled to be 2mm, the water flow direction is orthogonal to the laser scanning direction, the water flow speed is 0.1m / s, the original water temperature is 20°C, and the side blowing device is placed horizontally. Adjust the laser power to 500W; the scanning speed is 2mm / s; the flow rate of the side blowing device is 50L / mi...

Embodiment 2

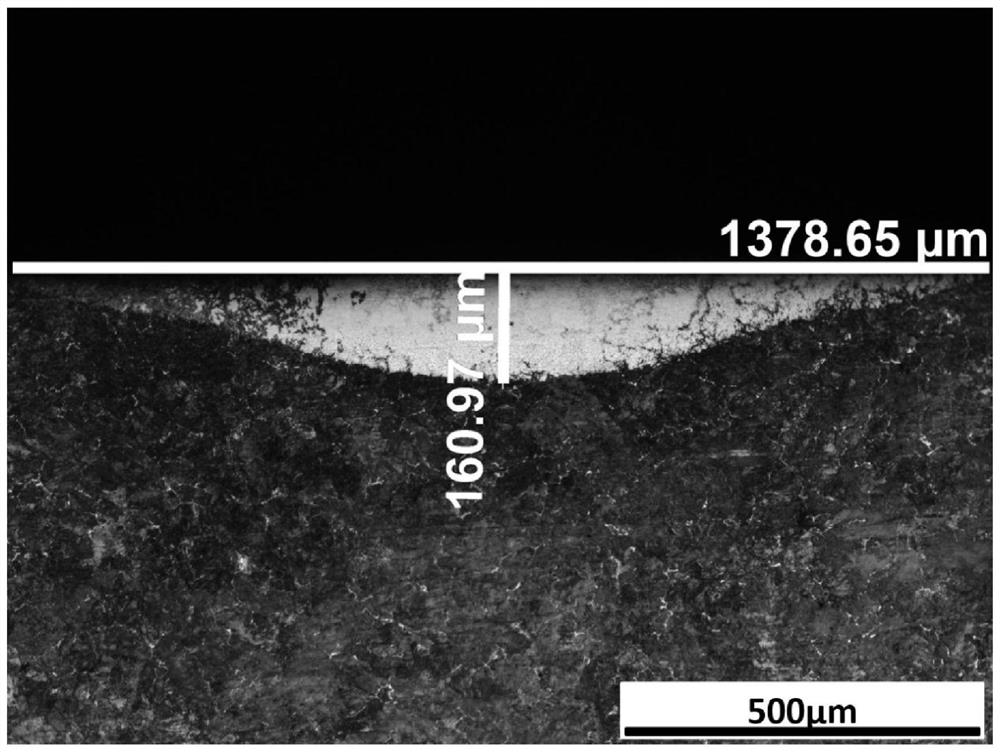

[0028] In this example, the laser power in Example 1 is increased to 800W, and other process parameters are guaranteed to be consistent with Example 1, and the cross-sectional view of the hardened layer of the sample is obtained ( figure 2 shown), compare figure 1 It can be found that the width of the quenching layer and the depth of the quenching layer increase significantly when the laser power increases.

Embodiment 3

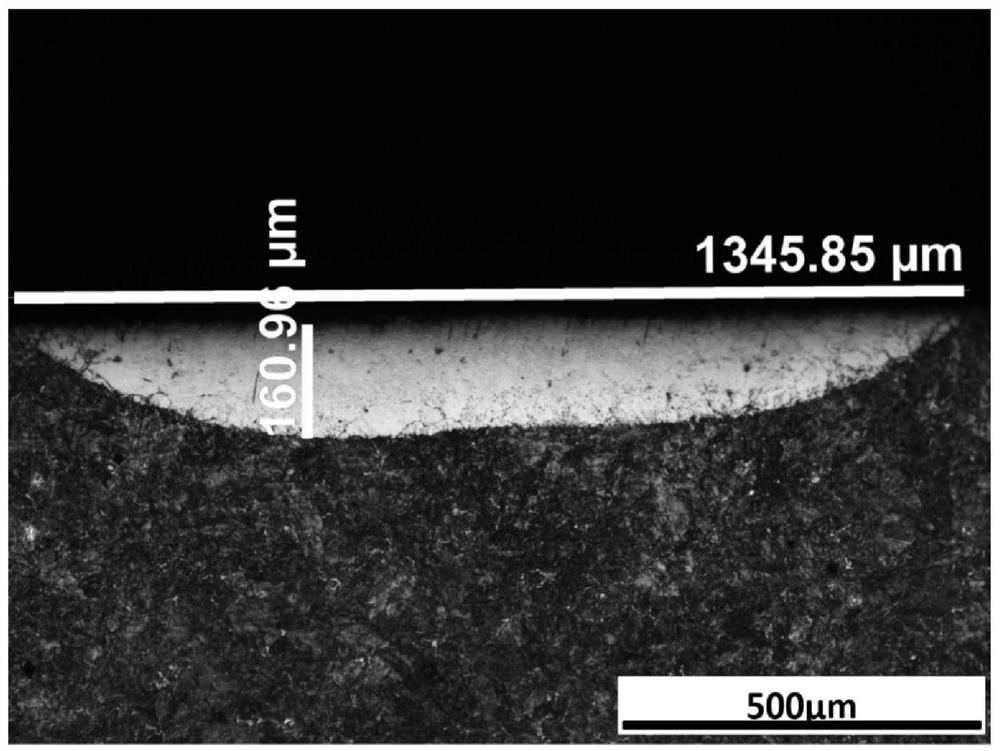

[0030] In this example, the thickness of the water layer in Example 2 is increased to 8mm, and other process parameters are guaranteed to be consistent with Example 2, and the cross-sectional view of the hardened layer of the sample is obtained ( image 3 shown), compare figure 2 It can be known that the thickness of the quenching layer and the width of the quenching layer are significantly reduced when the water layer is too thick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com