Shock absorption and noise reduction integral welding type comb plate expansion joint

A welded, comb-tooth plate technology, applied to bridge parts, bridge materials, bridges, etc., can solve problems such as low efficiency, safety accidents, and long time consumption, and achieve enhanced anchorage, improved connection strength, and strong anchorage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

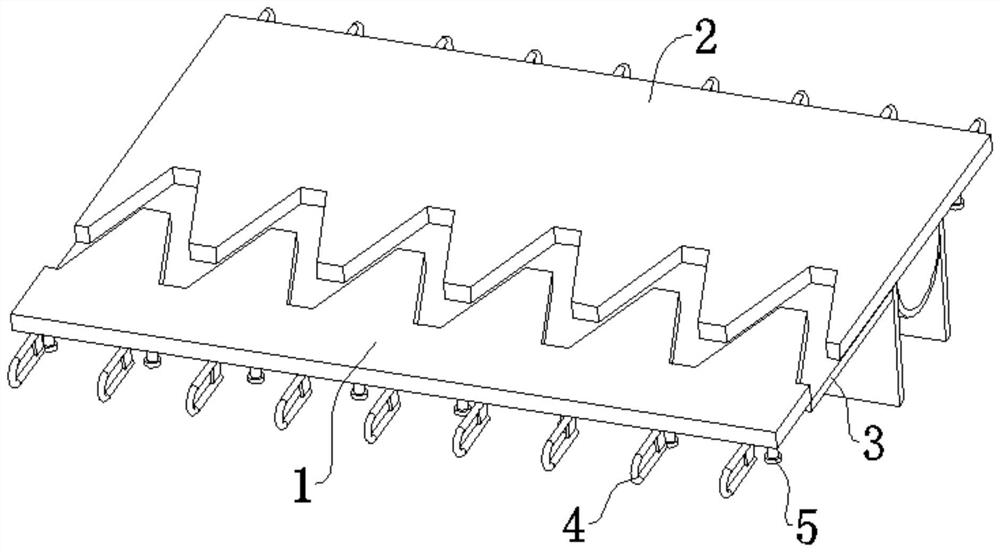

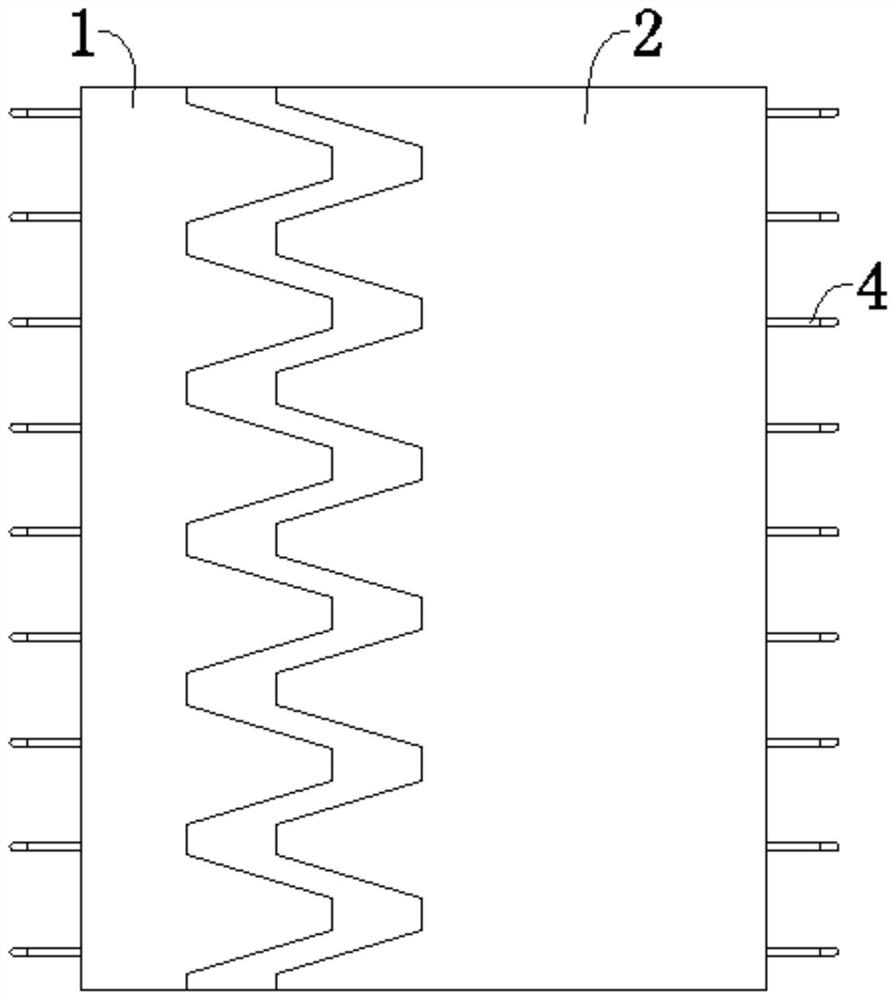

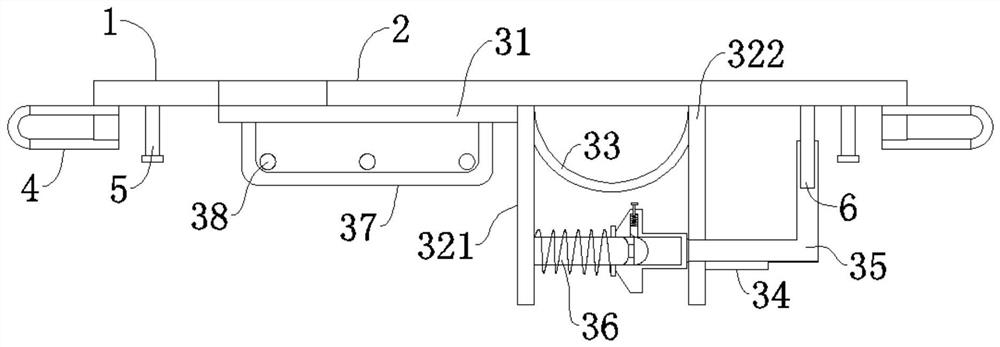

[0035] Embodiment: a shock-absorbing and noise-reducing integrally welded comb-tooth plate expansion joint, such as Figure 1-5 As shown, it includes a fixed tooth plate 1, a movable tooth plate 2 and a bracket 3. Both the fixed tooth plate 1 and the movable tooth plate 2 are supported on the bracket 3, and both the fixed tooth plate 1 and the movable tooth plate 2 are provided with comb teeth. Specifically, the fixed tooth plate 1 and the bracket 3 are welded and fixed. There is a certain distance between the fixed tooth plate 1 and the movable tooth plate 2 so that the comb teeth on the fixed tooth plate 1 do not contact with the comb teeth on the movable tooth plate 2 . An anchor ring 4 and a welding stud 5 are fixed on the fixed tooth plate 1 and the movable tooth plate 2 , and the anchor ring 4 is fixed on the outer side of the fixed tooth plate 1 and the outer side of the movable tooth plate 2 . The welding stud 5 is fixed on the bottom of the fixed tooth plate 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com