Bridge transverse anti-overturning performance improving and transforming method

An anti-overturning and transverse technology, applied in bridges, bridge construction, bridge maintenance, etc., can solve the problems of high risk of overturning instability and poor anti-torsion deformation ability of transverse bridges, and achieve simple operation, clear structural force, and economical good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

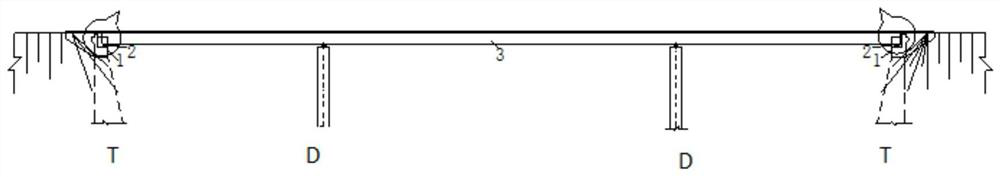

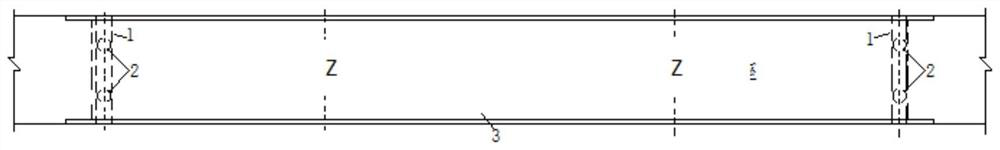

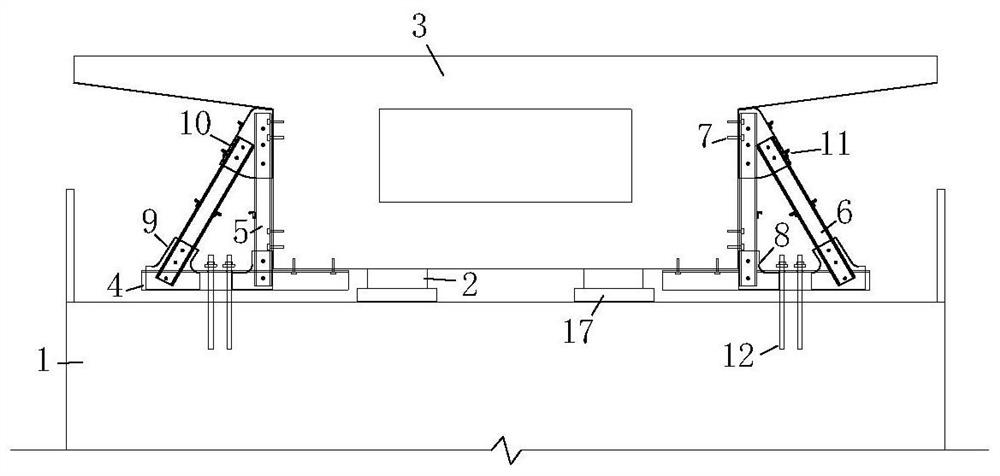

[0025] Such as Figure 1 to Figure 9 As shown, the present invention provides a kind of bridge transverse anti-overturning performance improvement transformation method, comprises the following steps:

[0026] A single-column pier bridge box girder 3 is integrally lifted, the lower chord 4 and the bottom slab of box girder 3 are fixed by chemical anchors 7, the two ends of the lower chord 4 are cantilevered and protrude from the bottom slab of box girder 3, and the lower chord 4 is fixed After the completion, the box girder 3 integrally falls back as a whole;

[0027] The middle pier of the bridge is a single-column pier, on which a single support is set, the double support 2 on the abutment cover beam 1 on both sides is installed horizontally on the pad stone 17, and the cast-in-place integral box girder 3 is supported on the abutment support 2 and pier supports, see Figure 1 ~ Figure 2 , the box girder 3 is jacked up as a whole by a jack, and a hole is drilled at the desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com