Intelligent concrete vibrating device for lock chamber wall

A vibrating device and concrete technology, which are applied in ship lifting devices, ship locks, climate change adaptation, etc., can solve the problems of slow manual vibrating and vibrating progress, inability to effectively vibrate in dead corners, threats to workers' life safety, etc., and reduce labor. The effect of quantity loss, large engineering quantity and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments. In the description of the present invention, unless otherwise specified, "plurality" means two or more.

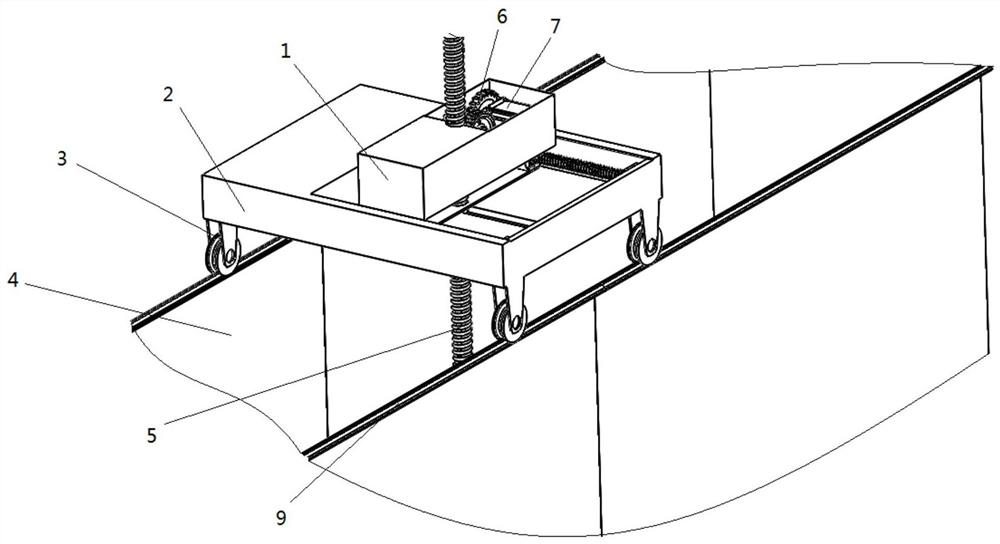

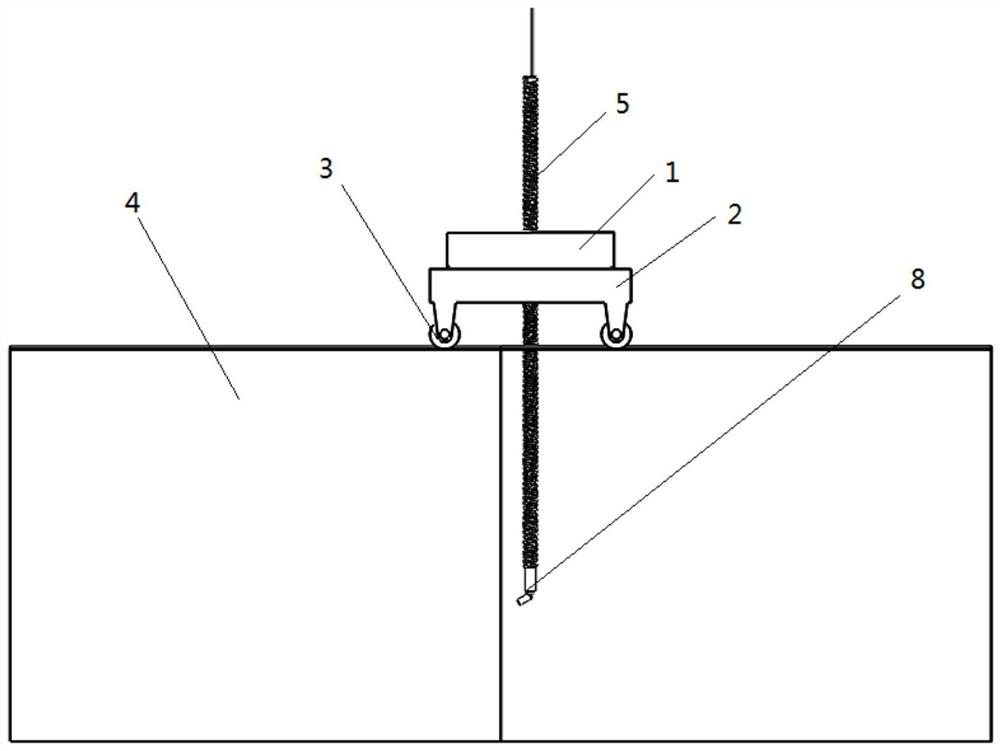

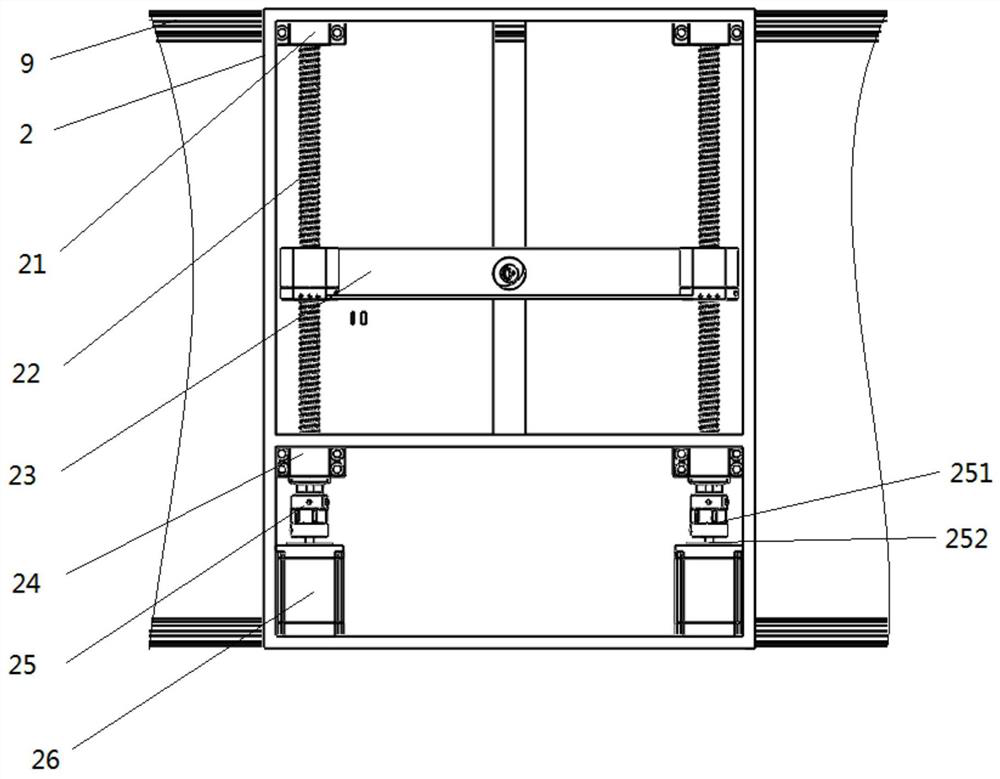

[0050] There is randomness in the guarantee of the quality of the lock chamber wall. Due to the limited skills of the construction personnel and the dock-type structure of the lock chamber wall, it is impossible to vibrate every part of the lock chamber wall with the existing equipment and operators; During the process, the construction personnel need to go deep into the bottom of the lock chamber wall more than ten meters deep to vibrate, which is very prone to safety accidents; the progress of manual vibration is slow, the construction efficiency is low, and the labor consumption is large. The purpose of the present invention is to provide a An intelligent vibrating device for the concrete of the lock chamber wall is used to solve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com