Combined pouring template for gap of outer side opening of smoke duct

A flue air duct and combined technology, which is applied to the field of pouring formwork and its support in the opening and gap outside the flue air duct, can solve the problems of water leakage of iron wire floor slabs, low recycling rate of hanging formwork formwork, etc., and achieves easy fixing, geometrical Small size deviation, easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The invention will be described in detail below with reference to the accompanying drawings:

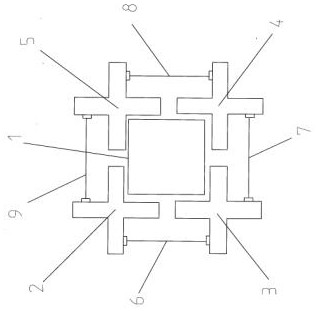

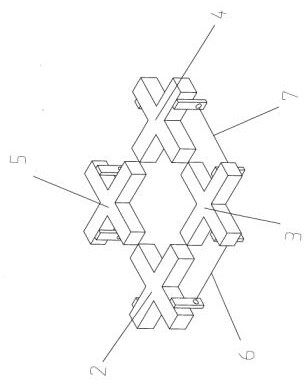

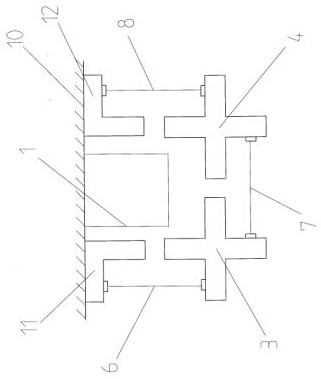

[0017]A combined pouring template of a smoke-shaped outer hole slit, including the floorboard, a smoke vent hole is provided in the middle of the floorboard, and a square smoke floral pipe body is provided in the smoke venting mouth, below the floor. On the four corners of the outer surface of the square smoke flop body 1, the first cross-shaped large cross-section steel template module 2, the second cross-shaped small section square steel template module 3, the first Three cross-shaped large section square steel template modules 4 and the fourth cross-shaped small section square steel template module 5, the first cross-shaped large section square steel template module 2 structure and the third cross-shaped large The structure of the cross-sectional square steel template module 4 is exactly the same, and the structure of the second cross-shaped small section steel template module 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com