Oil-cooled motor bearing lubricating structure

A technology of motor bearing and lubricating structure, applied in the direction of engine lubrication, shaft and bearing, bearing components, etc., can solve problems such as insufficient bearing lubrication, achieve stable and reliable lubrication, solve insufficient bearing lubrication, and improve feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

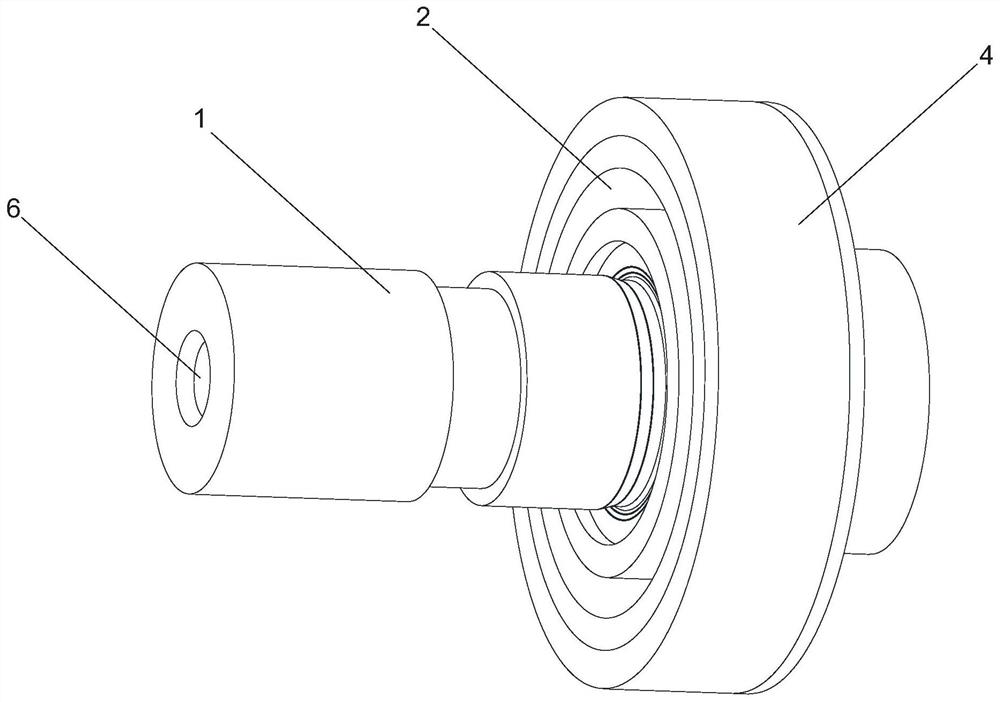

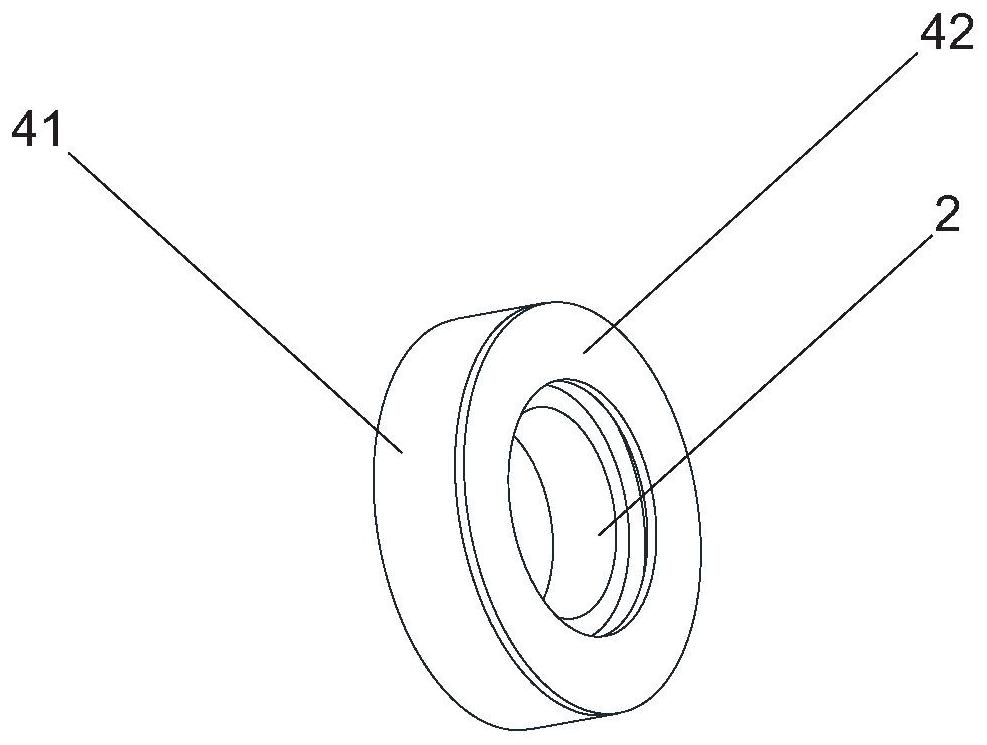

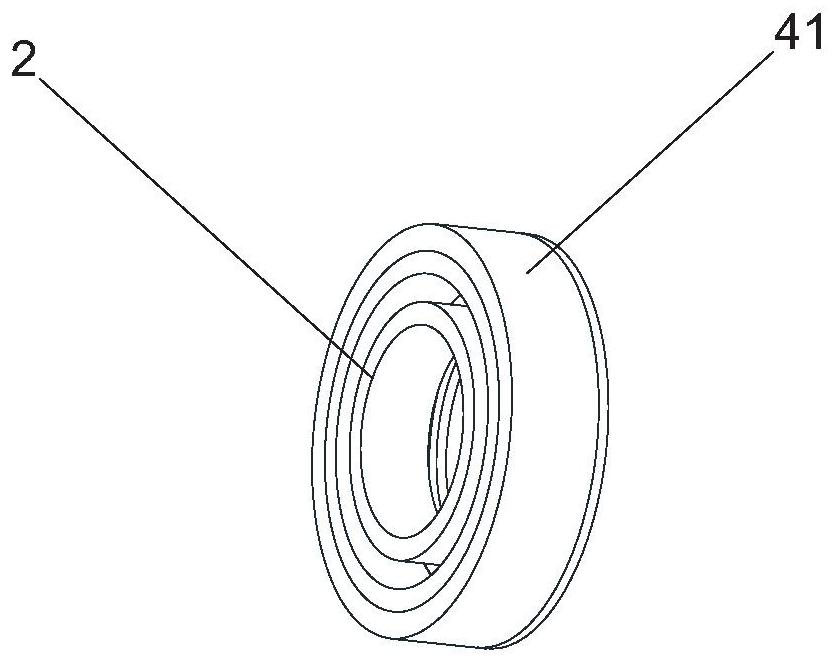

[0024] Such as Figure 1 to Figure 6 As shown, an oil-cooled motor bearing lubrication structure includes a rotor shaft 1 and a bearing 2, the bearing 2 is sleeved on the rotor shaft 1 and installed on the housing of the oil-cooled motor, and the rotor shaft 1 is provided with radial The oil supply channel 3 and the oil outlet port 5 of the radial oil supply channel 3 are located at the junction of the bearing 2 and the rotor shaft 1, and the bearing seat hole is provided with a bearing shoulder 4 that can prevent the oil from being thrown out centrifugally. The bearing retaining shoulder 4 includes an outer ring wall 41, an end face retaining ring 42 and a bearing supporting retaining ring 43, the outer ring wall 41 is located on the housing of the oil-cooled motor, and the end face retaining ring 42 is connected to the inner end surface of the outer ring wall 41, The bearing support retaining ring 43 is located at the junction of the outer ring wall 41 and the end face retai...

Embodiment 2

[0027] The outer ring wall 41 and the end face retaining ring 42 are integrally formed, and the bearing support retaining ring 43 is installed at the junction of the outer ring wall 41 and the end face retaining ring 42 . The inner peripheral surface of the outer ring of the bearing 2 is slightly higher than the bottom edge of the outer end surface of the bearing support retaining ring 43 . The included angle between the inclined plane and the axis of the bearing 2 is 28°. All the other are with embodiment 1.

Embodiment 3

[0029] The included angle between the inclined plane and the axis of the bearing 2 is 32°. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com