A thermodynamic exhaust system with precise temperature response and its control method

An exhaust system and thermodynamic technology, applied to the operation mode of the machine, refrigerator, refrigeration components, etc., can solve the problems of reduced pump efficiency, loss of propellant, increased liquid discharge, etc., to reduce power consumption and reduce exhaust Loss, effect of reducing circulation flow

Active Publication Date: 2022-06-03

XI AN JIAOTONG UNIV +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional TVS system still has the following problems: the fluid sprayed by the spray rod flows out from all nozzles, but only a few or even one nozzle plays a leading role in cooling the high temperature area, resulting in a decrease in pump efficiency and an increase in discharge, resulting in Unnecessary energy loss and propellant loss

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

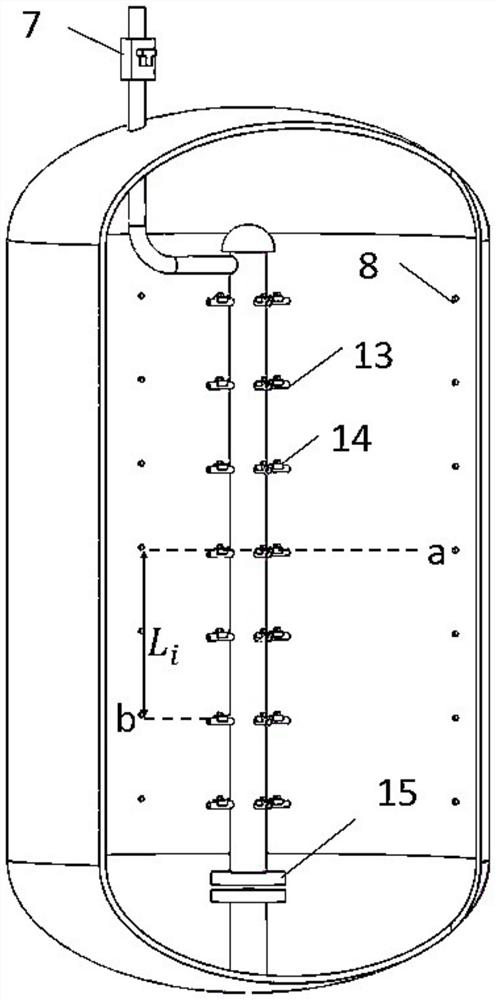

[0035] As a further limitation of the present invention, the spray bar includes a casing heat exchanger and a plurality of nozzles, so the

[0036] As a further limitation of the present invention, the temperature sensor is evenly arranged on the wall surface of the tank, and is one with the nozzle.

[0039]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

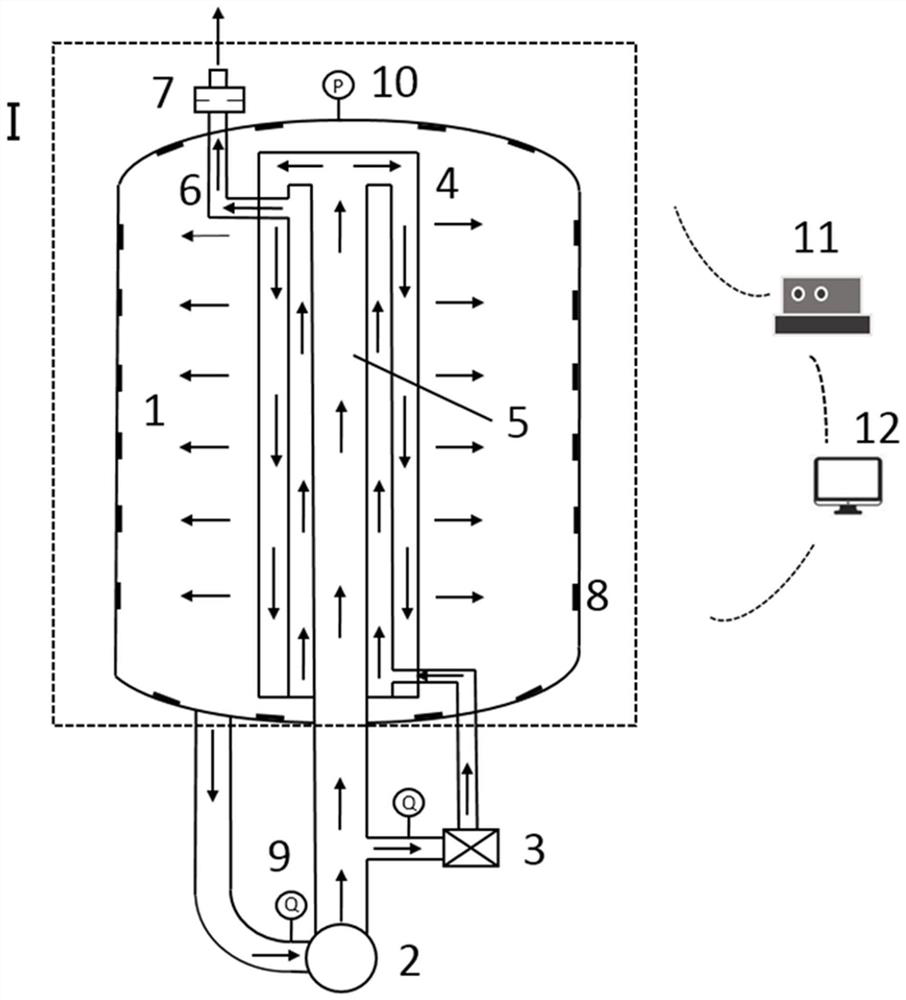

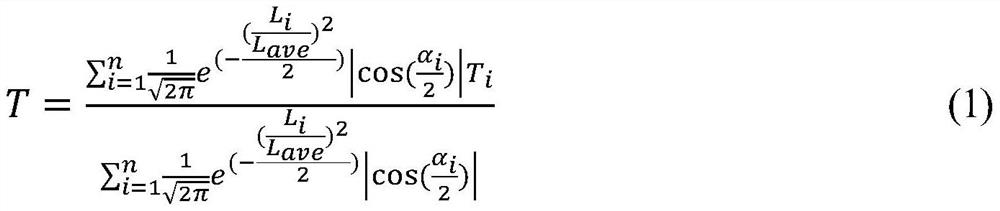

The invention discloses a thermodynamic exhaust system with precise temperature response and a control method thereof. Multiple sets of temperature sensors are arranged in a storage tank, and electromagnetic valves are installed on all nozzles. On-off of the nozzle, when the equivalent temperature of the local area exceeds the critical saturation temperature, the corresponding nozzle is opened, and the low-temperature fluid flows out from the nozzle to cool the corresponding area, realizing point-to-point precise temperature and pressure control; The difference adopts different temperature response strategies to control the on-off of each nozzle, thereby reducing the work required for the low-temperature circulating pump to pump the propellant, reducing the circulation flow and exhaust loss of the low-temperature propellant, and realizing the protection of the high-temperature area in the tank. Accurate response.

Description

A thermodynamic exhaust system with accurate temperature response and its control method technical field The present invention relates to a kind of thermodynamic exhaust system, particularly to a kind of thermodynamic exhaust system of accurate temperature response and its control method. Background technique Low temperature propellant has the characteristics of high fuel performance, non-toxicity, large specific impulse, etc., and can well meet the payload of spacecraft. and energy density requirements. Cryogenic liquids represented by liquid hydrogen, liquid oxygen, and liquid methane are still the propellants for future space spacecraft of choice. However, low temperature conditions impose more stringent requirements on the thermal insulation of on-orbit tanks. Even well insulated low Warm storage system, the heat leakage of space thermal environment is less than 5W / m 2 , will still cause the local temperature rise of the cryogenic propellant in the tank, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F25B19/04F25B41/30F25B49/00

CPCY02E60/32

Inventor 郑永煜刘迎文杨鹏闫春杰杨祺王小军

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com