Thermodynamic vent system with accurate temperature response and control method thereof

An exhaust system and thermodynamic technology, applied to the operation mode of the machine, refrigerators, refrigeration components, etc., can solve the problems of reduced pump efficiency, propellant loss, and increased liquid discharge, so as to reduce power consumption and energy consumption , temperature efficient and rapid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

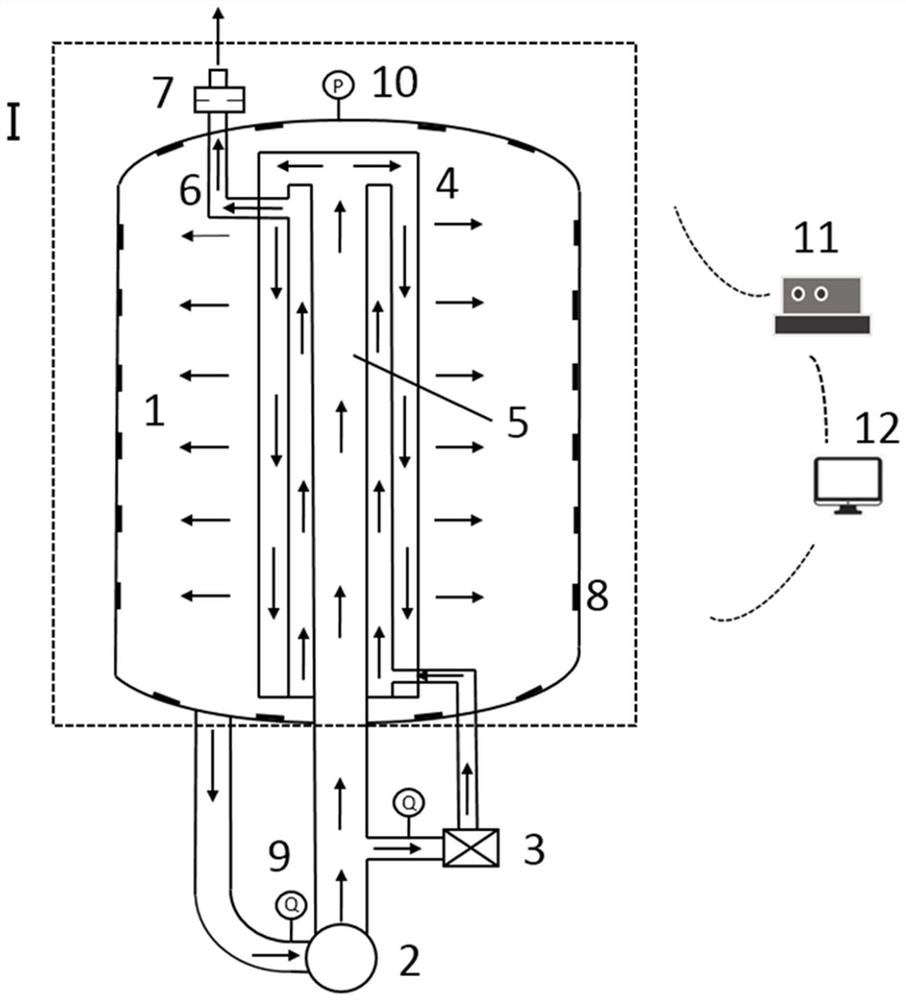

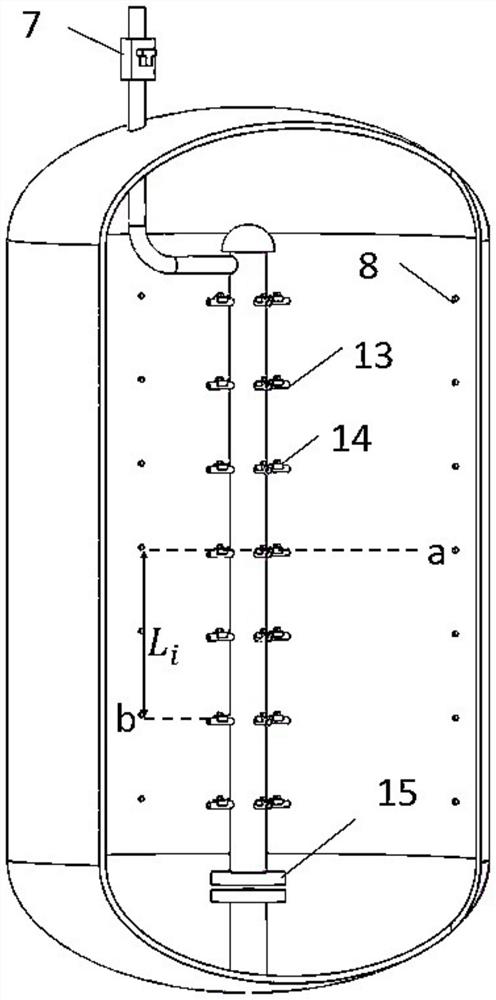

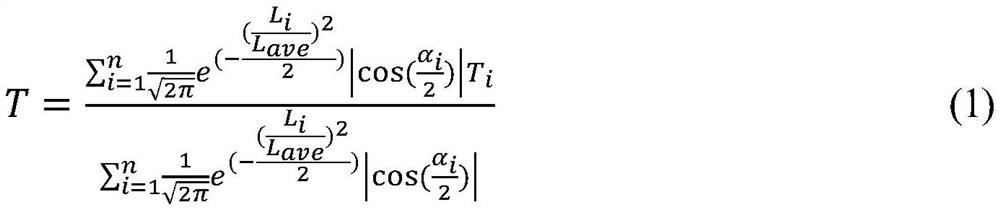

[0029] Such as figure 1 and figure 2 As shown, a thermodynamic exhaust system with precise temperature response of the present invention includes a storage tank 1, a low-temperature circulation pump 2, a throttle valve 3, a spray rod 4, a casing heat exchanger 5, a data acquisition instrument 11, and a computer 12 .

[0030] The storage tank 1 is a cylinder structure with elliptical heads at both ends and a cylinder in the middle. The storage tank is a low-temperature storage tank on which multiple layers of variable-density heat insulation materials are laid. The storage tank 1 is used to store propellants. The upper and lower walls of the box are respectively connected with a propellant exhaust pipe 6 and a circulation pipeline; the exhaust pipe 6 is provided with an exhaust port solenoid valve 7, which completes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com