Nitrogen-enriched flushing inerting piping system for commercial large aircraft fuel tanks

A technology for aircraft fuel tanks and pipeline systems, applied in the direction of fuel tank safety measures, etc., can solve the problems of environmental control system impact, large gas consumption, etc., and achieve the effects of precise control, reasonable proportioning, and optimization of system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

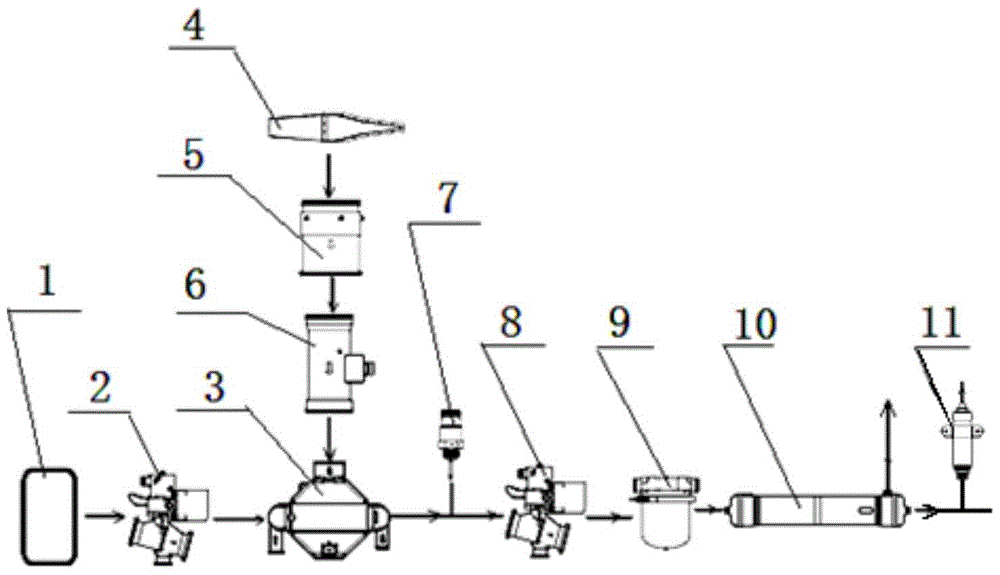

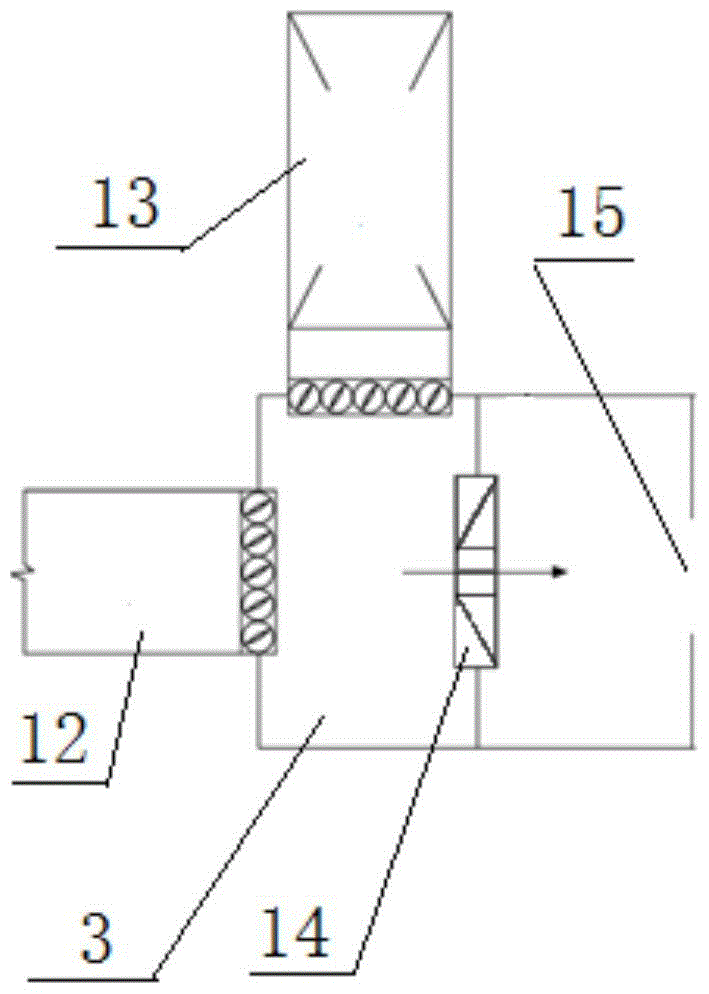

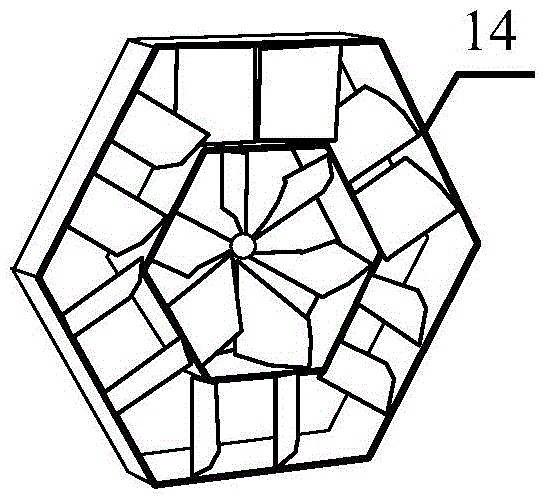

[0026] Embodiment 1: as attached figure 1 As shown, the air inlet 1 and the NACA air inlet 4 of the environmental control system are respectively connected to the air mixing and pressure stabilizing device 3, and then connected to the filter 9, and then connected to the air separation module 10; The NACA air inlet 4 introduces high-temperature and high-pressure gas and external air. After being mixed and stabilized by the air mixing and voltage stabilizing device 3, it passes through the air separation module 10, so that the mixed gas is divided into two streams, and the nitrogen-rich gas enters the fuel tank along the way. The other oxygen-enriched gas is directly discharged to the external environment.

[0027] In the foregoing, the front cut-off valve 2 is installed between the air inlet 1 of the environmental control system and the air mixing and pressure stabilizing device 3 .

[0028] In the foregoing, an adjustable intake valve 5 is installed between the NACA air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com