Robot vision detection method for multi-category mixed line production control cabinet

A robot vision and production control technology, applied in instruments, measuring devices, computer parts, etc., can solve problems such as high cost, large floor space, and inability to apply flexible inspection of mixed-line production products, achieving small floor space, The effect of less hardware and easier implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

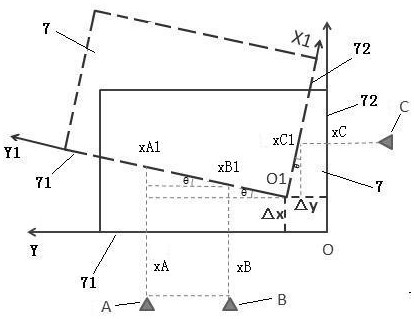

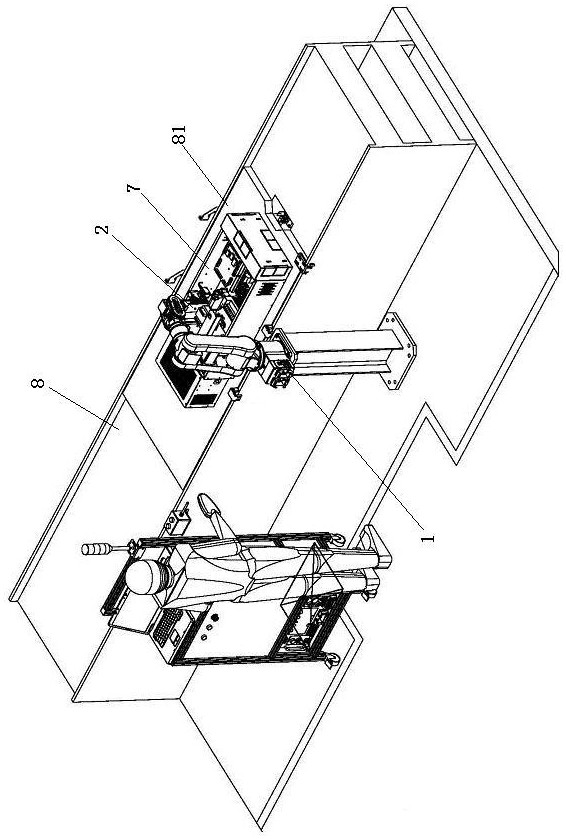

[0017] According to an embodiment of the present invention, a robot vision inspection method for multi-category mixed-line production control cabinets includes:

[0018] By teaching the robot, the visual sensor installed on the robot will take pictures of all the inspection points of all types of non-defective control cabinets, obtain the standard image templates of all inspection points, and generate the inspection operation program;

[0019] The robot receives the model information of the control cabinet to be tested and the information of non-standard detection points;

[0020] Based on the received model information and non-standard detection point information, the robot determines all the detection points that the current control cabinet to be detected needs to detect, and skips the program segments related to the detection points that the current control cabinet to be detected does not need to detect when running the detection operation program , only execute the program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com