Apparatus and method for acoustic modeling of defects in composite materials using calibration panels formed by additive manufacturing

A composite material, additive manufacturing technology, used in material analysis, manufacturing tools, additive manufacturing, etc. using sonic/ultrasonic/infrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Throughout this specification, reference to "one example," "an example," or similar language means that a particular feature, structure, or characteristic described in connection with the example is included in at least one example of the present invention. Appearances of the phrases "in one example," "in an example," and similar language throughout this specification may, but do not necessarily, all refer to the same example. Similarly, use of the term "embodiment" refers to an embodiment having a particular feature, structure, or characteristic described in connection with one or more examples of the invention, however, if there is no express nexus to indicate otherwise, then the embodiment Can be associated with one or more instances.

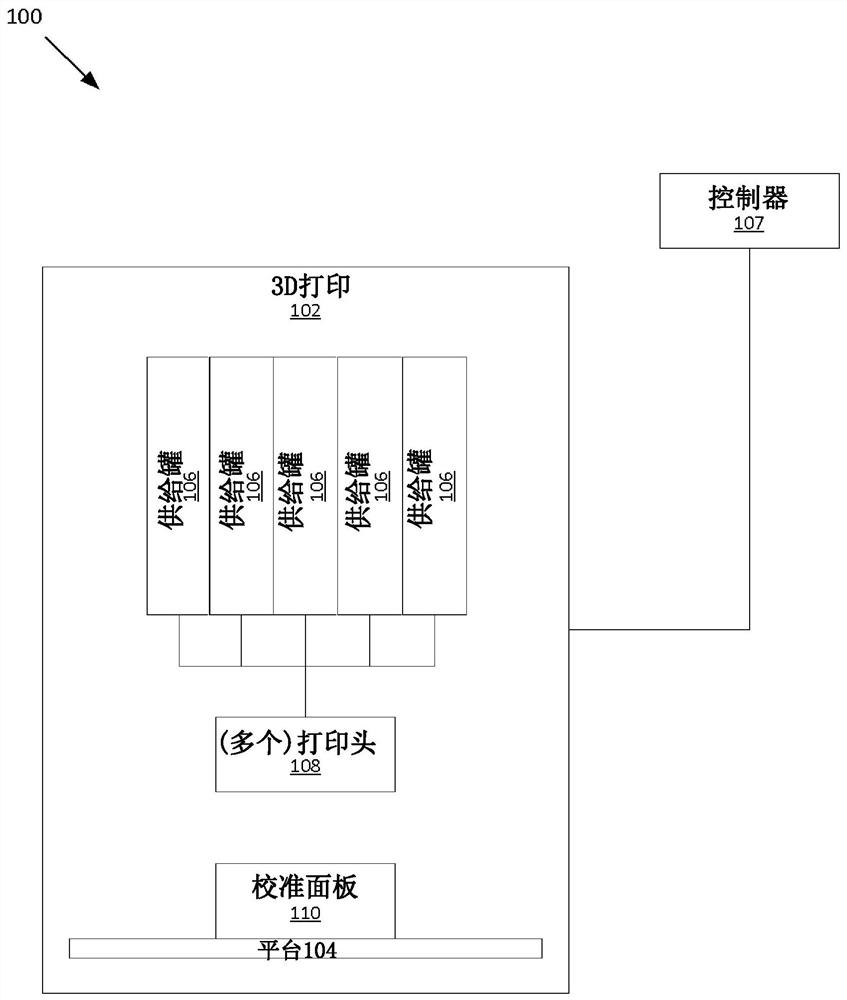

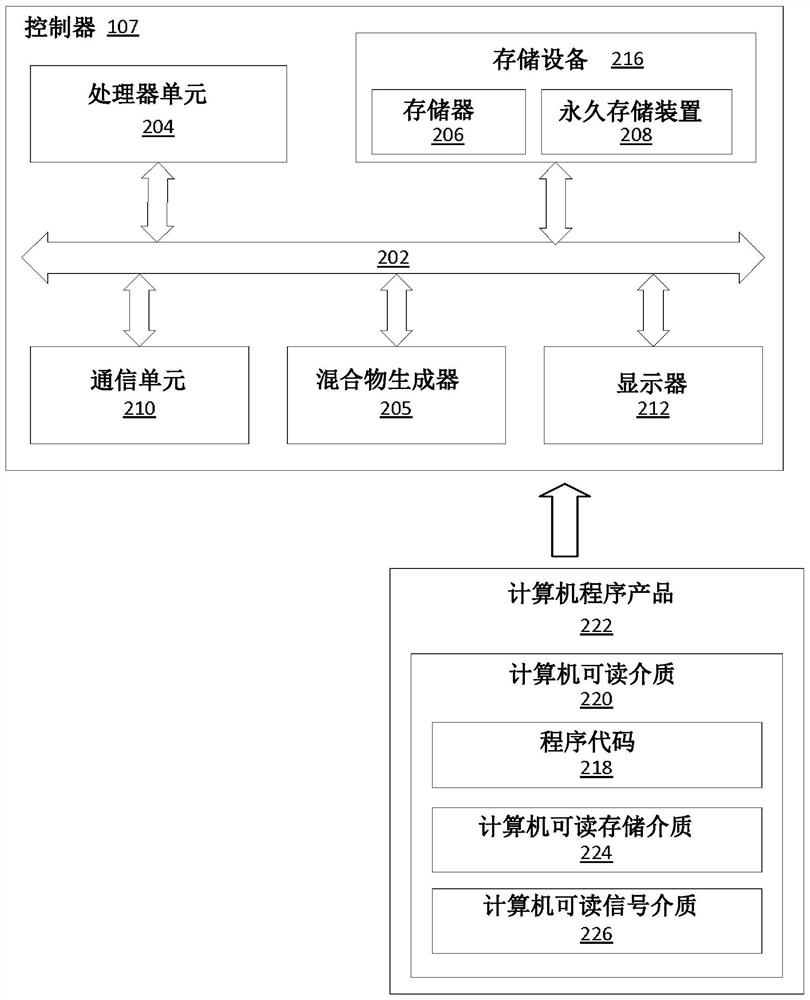

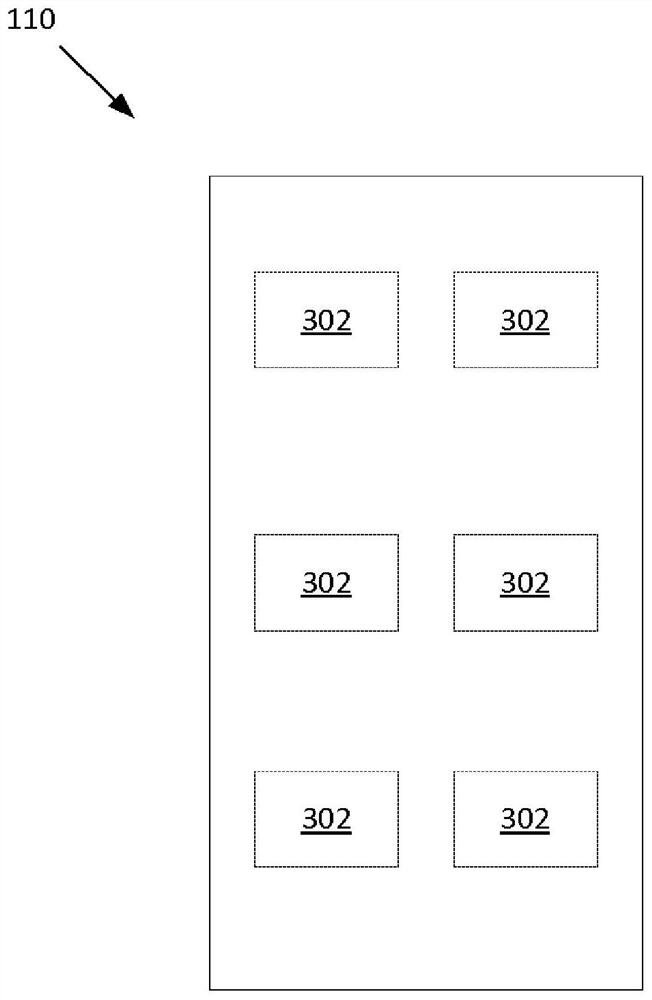

[0040] This disclosure describes an apparatus and method for fabricating, in some examples by additive manufacturing, a reference panel (eg, a calibration panel) that simulates the acoustic properties of a vehicle component or part. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap