High-power high-frequency induction heating power supply

A high-frequency induction heating and high-power technology, which is applied in the direction of cooling/ventilation/heating transformation, support structure installation, etc., can solve the problems of untimely heat dissipation of electrical components, affecting the work of electrical components, damage, etc., and achieves locking and unlocking operations Convenience, solution to uneven heat dissipation, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

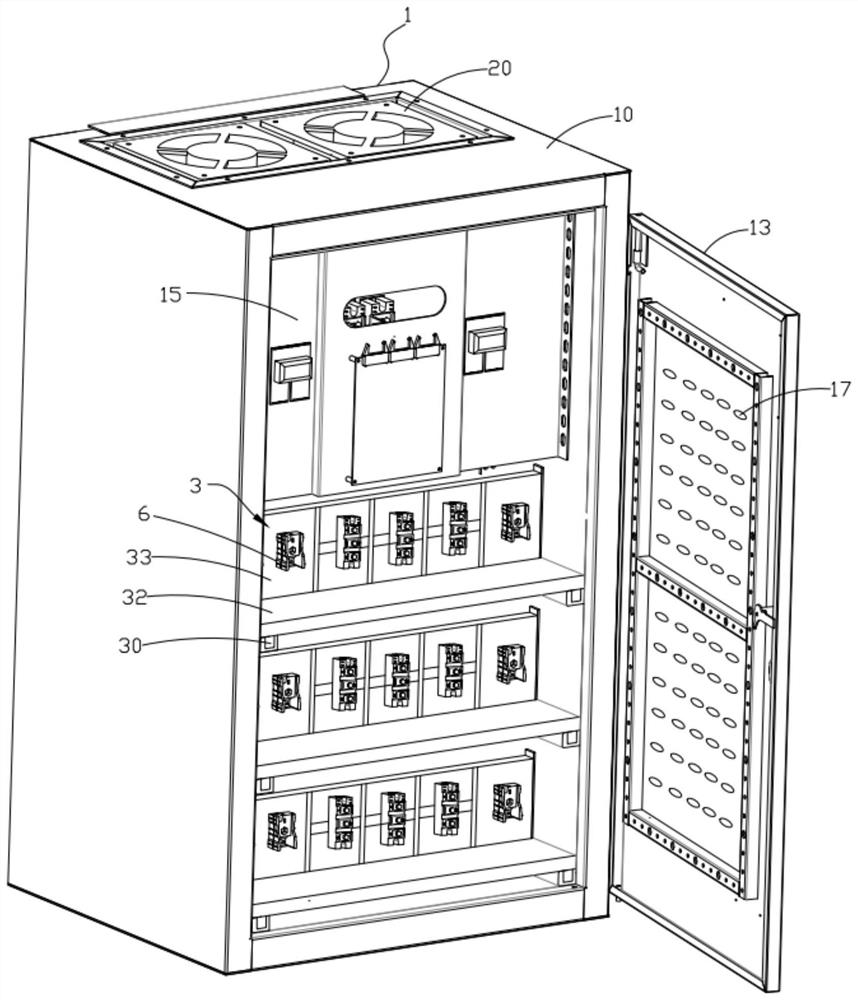

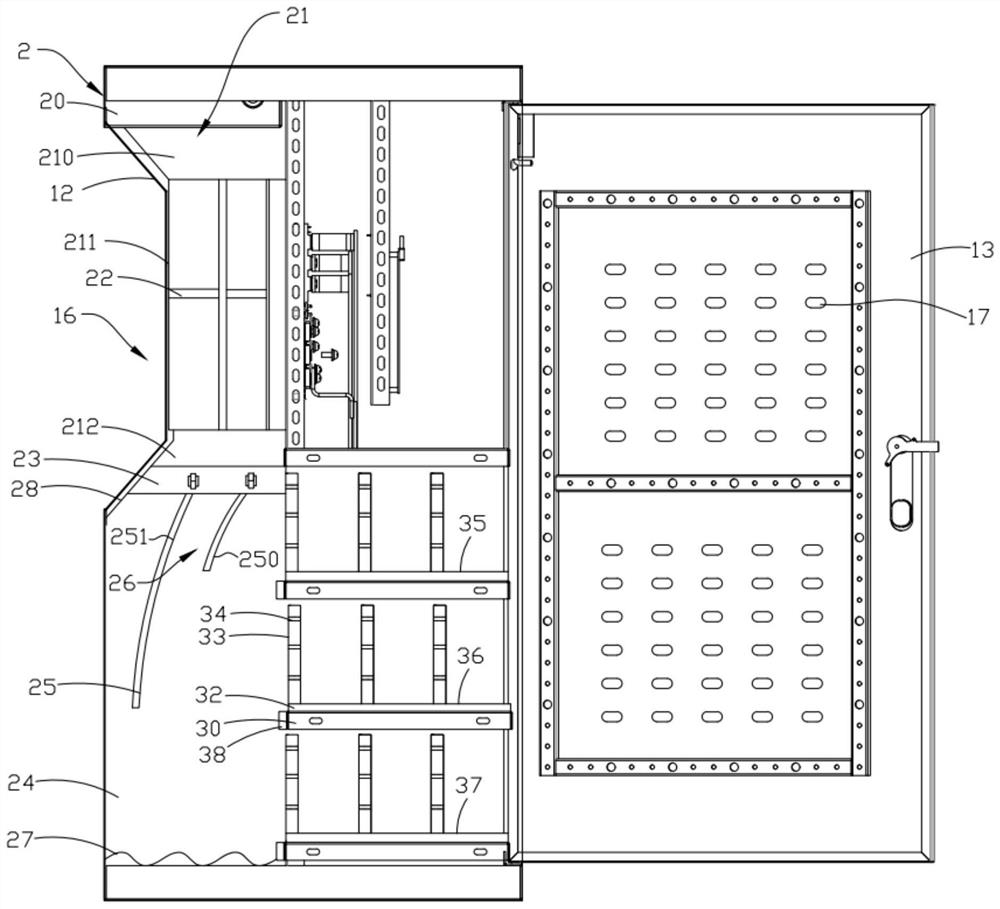

[0049] Such as Figure 1-2 As shown, a high-power high-frequency induction heating power supply in this embodiment includes: a cabinet 1, a heat dissipation assembly 2 arranged in the cabinet 1, and N pull-out components arranged in the cabinet 1 for installing electrical components 6 Mounting bracket assembly 3,

[0050] The cooling assembly 2 includes a fan 20 arranged on the top plate 10 of the cabinet 1, a cooling chamber 21 formed in the upper part of the cabinet 1, a cooling device 22 arranged in the cooling chamber 21, and a dehumidification device arranged on the air outlet side of the cooling device 22. The device 23, the air distribution chamber 24 formed in the lower part of the cabinet 1, and several air distribution partitions 25 arranged in the air distribution chamber 24, the several air distribution partitions 25 form N pieces corresponding to the pull-out mounting frame assembly 3 The air distribution channel 26 is provided with several air outlet holes 17 on...

Embodiment 2

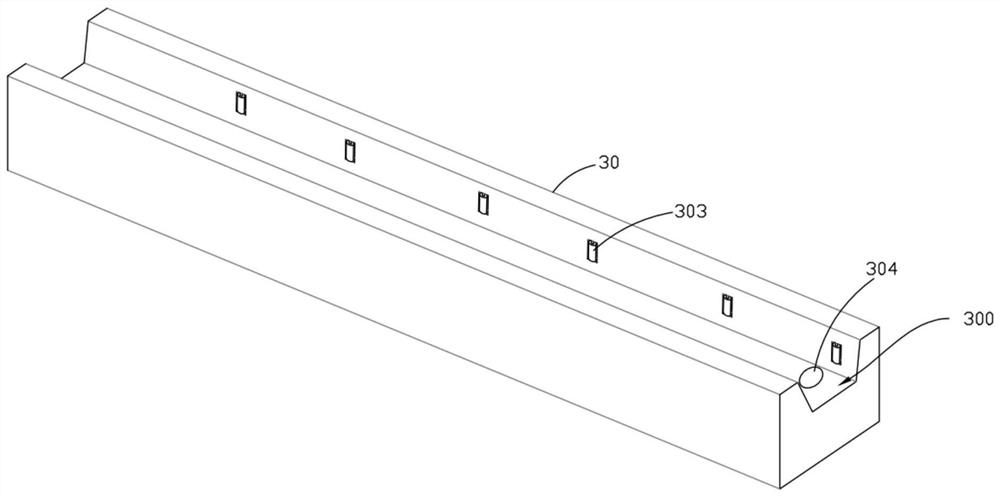

[0068] further reference Figure 3-11 , as a further improvement on the basis of Embodiment 1, in this embodiment, a slide groove 300 with an inverted trapezoidal cross section is provided on the slide rail 30, and the slide bar 31 can be slidably arranged in the slide groove 300, and the transverse direction of the slide bar 31 The cross section is an inverted trapezoid matching with the chute 300;

[0069] The inclined inner walls on both sides of the chute 300 are evenly spaced with a plurality of pulleys 303 grooves 301, the pulleys 303 are pivotally connected to the pulleys 303 through the rotating shaft 302 in the grooves 301, and the arrangement of the pulleys 303 makes the sliding bar 31 slide in the chute 300, The pulley 303 rolls around the rotating shaft 302 .

[0070] In this embodiment, the fit of the inverted trapezoid makes the cooperation between the slide bar 31 and the chute 300 more stable, and the slide bar 31 can be adaptively positioned in the chute 300 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap