Chestnut food preparation method

A technology of food preparation and chestnuts, which is applied in the field of chestnut food preparation, can solve problems such as complexity, difficulty in operation, and difficulty in storage of chestnut noodles and pastries, and achieve the effects of avoiding pollution, promoting fermentation, and maintaining indoor temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

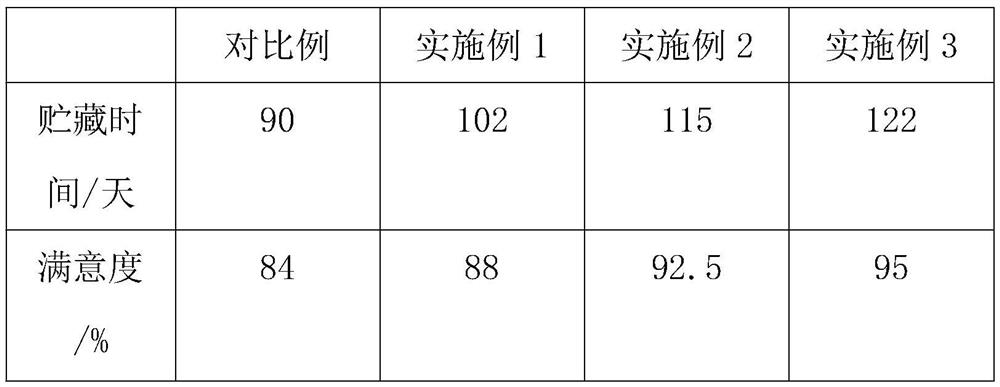

Embodiment 1

[0031] Step 1: Basic preparations: clean and disinfect relevant equipment, thoroughly clean surface bacteria, debug equipment functions, and sort relevant materials;

[0032] Step 2: Preparation of qualified bacterial liquid: heat the pure water to boiling, then let it cool to 25 degrees Celsius, pour the mucormyces spores into the pure water, stir the mixed solution, adjust the pH of the bacterial liquid, and stir evenly after debugging , heat preservation spare;

[0033] Step 3: Basic production of chestnut noodles: After grinding the chestnuts into powder, repeatedly rolling the chestnut noodles, then sieving the powdered chestnut noodles, or directly purchasing chestnut noodles to sieve, and stably collecting the sifted chestnut noodles;

[0034] Step 4: The basic operation of the main ingredients: mix the chestnut noodles and water, mix well, put the dough at room temperature and let it stand for 10 minutes, steam the chestnut noodles with a thickness of 1 cm, spread them...

Embodiment 2

[0039] Step 1: Basic preparations: clean and disinfect relevant equipment, thoroughly clean surface bacteria, debug equipment functions, and sort relevant materials;

[0040]Step 2: Preparation of qualified bacterial liquid: heat the pure water to boiling, then let it cool to 27.5 degrees Celsius, pour the mucormyces spores into the pure water, stir the mixed solution, adjust the pH of the bacterial liquid, and stir evenly after debugging , heat preservation spare;

[0041] Step 3: Basic production of chestnut noodles: After grinding the chestnuts into powder, repeatedly rolling the chestnut noodles, then sieving the powdered chestnut noodles, or directly purchasing chestnut noodles to sieve, and stably collecting the sifted chestnut noodles;

[0042] Step 4: The basic operation of the main ingredients: mix the chestnut noodles and water, mix well, put the dough at room temperature and let it stand for 15 minutes, steam the chestnut noodles with a thickness of 1.1 cm, spread t...

Embodiment 3

[0047] Step 1: Basic preparations: clean and disinfect relevant equipment, thoroughly clean surface bacteria, debug equipment functions, and sort relevant materials;

[0048] Step 2: Preparation of qualified bacterial liquid: heat the pure water to boiling, then let it cool to 30 degrees Celsius, pour the mucormyces spores into the pure water, stir the mixed solution, adjust the pH of the bacterial liquid, and stir evenly after debugging , heat preservation spare;

[0049] Step 3: Basic production of chestnut noodles: After grinding the chestnuts into powder, repeatedly rolling the chestnut noodles, then sieving the powdered chestnut noodles, or directly purchasing chestnut noodles to sieve, and stably collecting the sifted chestnut noodles;

[0050] Step 4: The basic operation of the main ingredients: mix the chestnut noodles and water, mix well, put the dough at room temperature and let it stand for 20 minutes, steam the chestnut noodles with a thickness of 1.2 cm, spread th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap