Waste gas treatment device for industrial boiler

A technology for waste gas treatment devices and industrial boilers, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, which can solve the problems of difficult gas discharge and exhaust gas purification, and achieve the effect of ensuring the quality of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

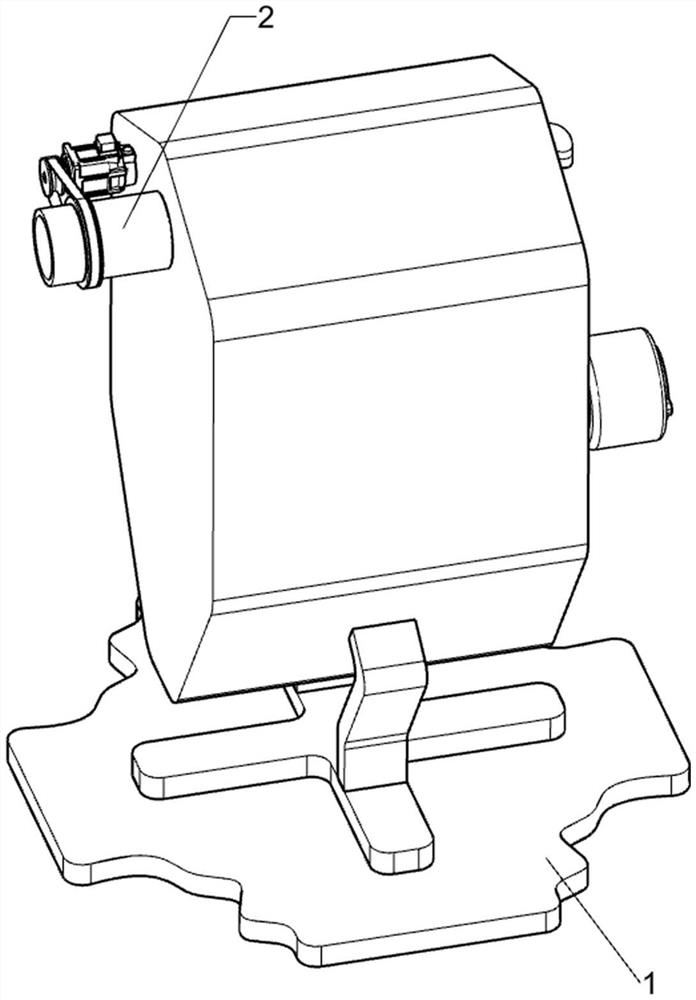

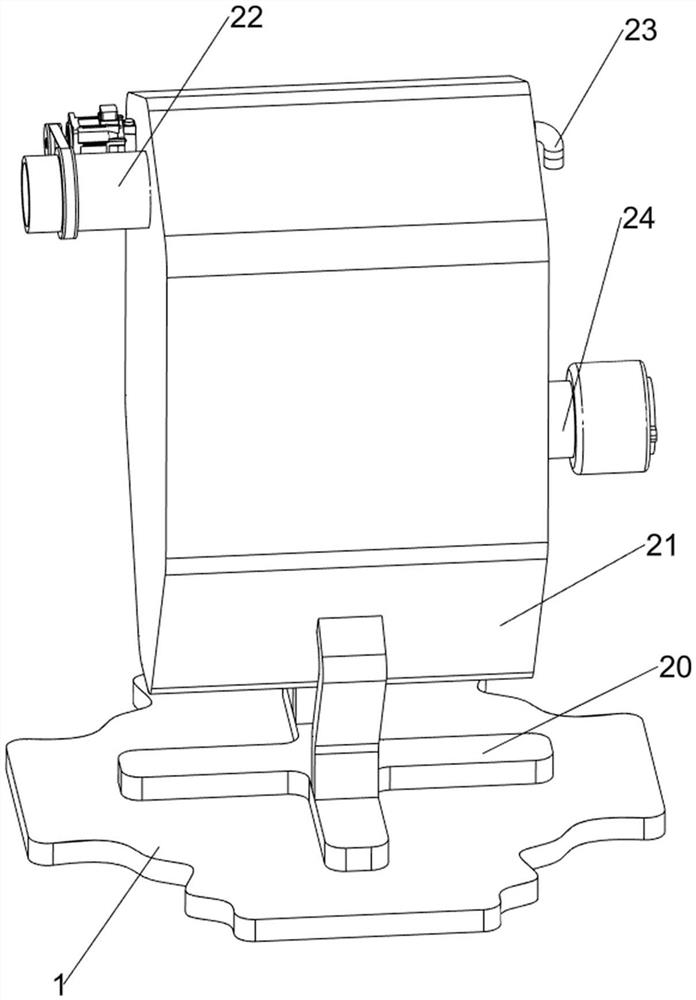

[0056] A waste gas treatment device for industrial boilers, such as Figure 1 to Figure 5 As shown, it includes a base 1 , an exhaust mechanism 2 and a purification mechanism 3 , the top of the base 1 is provided with an exhaust mechanism 2 , and the exhaust mechanism 2 is connected with a purification mechanism 3 .

[0057] The exhaust mechanism 2 includes a support 20, a first installation box 21, a first rubber tube 22, a vent pipe 23 and an air outlet pipe 24, the top of the base 1 is provided with a support 20, and the support 20 is provided with a first installation box 21, the first The rear side of the installation box 21 has a working port, the left side of the first installation box 21 is provided with a first rubber tube 22, the right side of the first installation box 21 is provided with a vent pipe 23, and the right side of the first installation box 21 is provided with an outlet. Trachea24.

[0058] The purification mechanism 3 includes a first connection block ...

Embodiment 2

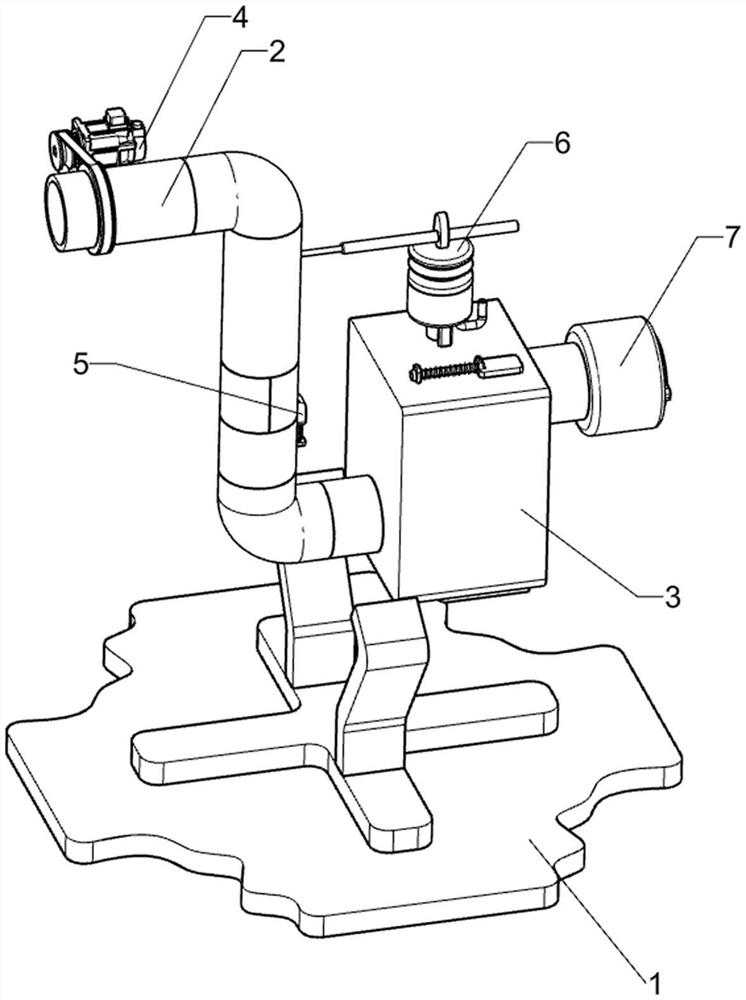

[0061] On the basis of Example 1, such as Figure 6 to Figure 14As shown, a rotating mechanism 4 is also included, and the rotating mechanism 4 includes a servo motor 40, a second rubber tube 41, a belt drive assembly 42, a second connecting block 43 and a first blade 44, and the left side of the first installation box 21 is provided with There is a servo motor 40, a second rubber tube 41 is connected to the left side of the first rubber tube 22, and a second connecting block 43 is rotatably connected to the second rubber tube 41, and a plurality of first blades 44 are arranged in the second connecting block 43 A belt drive assembly 42 is connected between the output shaft of the servo motor 40 and the second connecting block 43 .

[0062] Also include filter mechanism 5, filter mechanism 5 includes filter tube 50, second mounting block 51, second slide block 52 and second spring 53, first rubber tube 22 is slidably provided with filter tube 50, the first rubber tube The tube...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap