White radish cutting equipment for food processing

A technology for cutting equipment and food processing, applied in metal processing, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as easy to cut hands, low efficiency of manual cutting, uneven cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

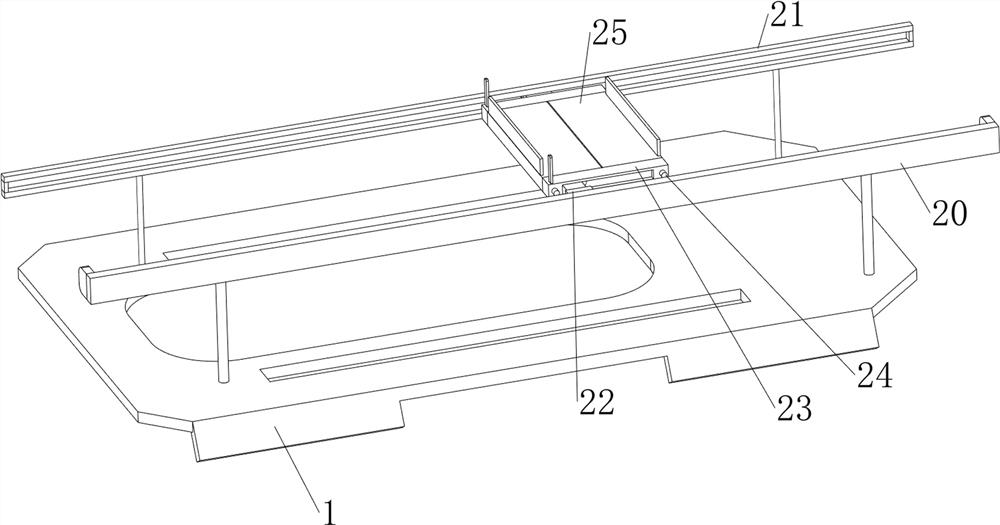

[0056] A food processing white radish cutting equipment, such as figure 1 As shown, it includes a base plate 1 , a moving mechanism 2 and a cutting mechanism 3 , the moving mechanism 2 is provided on the top of the base plate 1 , and the cutting mechanism 3 is provided on the right side of the top of the base plate 1 .

[0057] The staff can place the radish on the moving mechanism 2, start the moving mechanism 2 to drive the radish to move to the right under the cutting mechanism 3, and at the same time, the moving mechanism 2 drives the cutting mechanism 3 to operate to cut the radish. After cutting, stop the operation of the moving mechanism 2 , just collect the cut radishes.

Embodiment 2

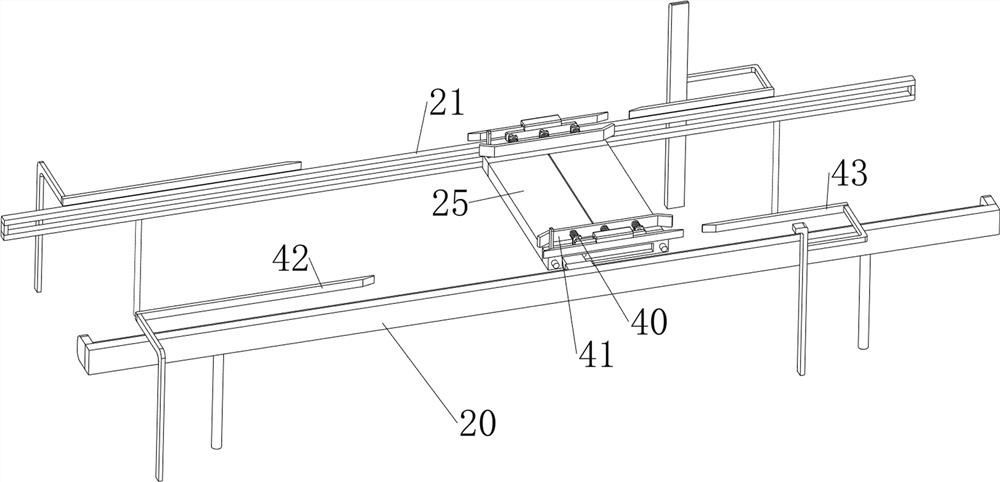

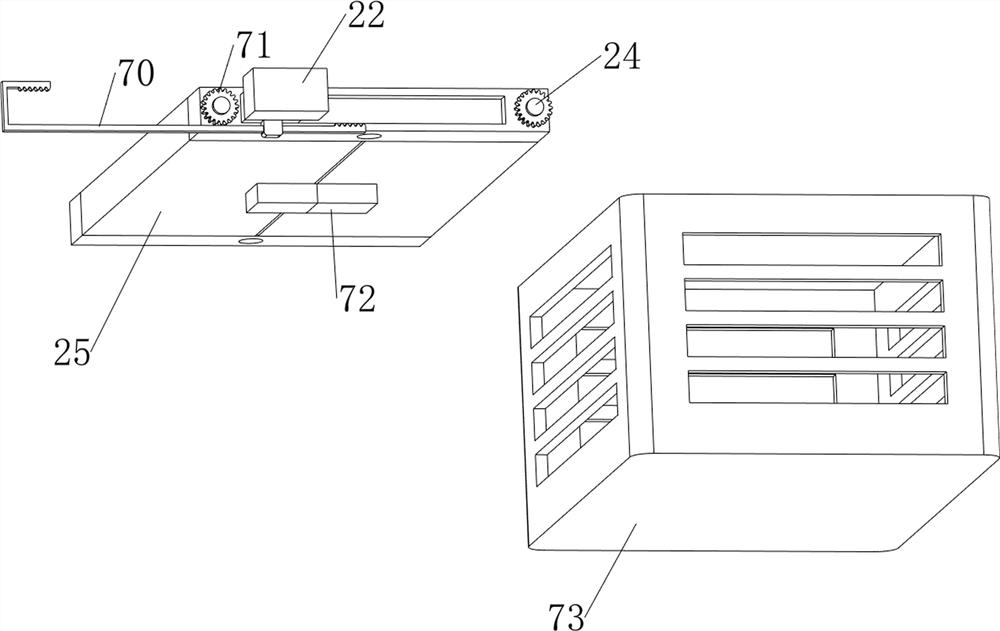

[0059] On the basis of Example 1, such as figure 2 and image 3 As shown, the moving mechanism 2 includes a rodless cylinder 20, a guide groove 21, a movable block 22, a moving plate 23, a first rotating shaft 24, and a rotating plate 25. The side is provided with guide groove 21, and rodless cylinder 20 and guide groove 21 are all provided with movable block 22, and movable block 22 inner side is all slidably connected with movable plate 23, and the outer side of movable plate 23 is provided with rubber ball, and movable plate 23 left and right sides Both sides are rotatably provided with a first rotating shaft 24 , and a rotating plate 25 is connected to the first rotating shaft 24 , and the rotating plate 25 engages with the moving plate 23 .

[0060]The cutting mechanism 3 includes a support plate 30, a first support rod 31, a movable rod 32, a first spring 33, a cutter 34, a second movable frame 35, a movable column 36, a second spring 37, a clamping column 38 and a wed...

Embodiment 3

[0063] On the basis of Example 2, such as Figure 4 to Figure 9 As shown, a clamping mechanism 4 is also included, and the clamping mechanism 4 includes a first fixed plate 40, a clamping plate 41, a first wedge block 42, a second wedge block 43, a third wedge block 44 and a third spring 45. Three first fixing plates 40 are arranged on the top of the plate 23, and a clamping plate 41 is slidably arranged between the first fixing plates 40. A third spring 45 is connected between the clamping plate 41 and the inner side of the first fixing plate 40, and the outside of the clamping plate 41 is connected There is a third wedge 44, a first wedge 42 is arranged symmetrically on the left side of the top of the bottom plate 1, and a second wedge 43 is arranged symmetrically on the right side of the top of the bottom plate 1, and the second wedge 43 and the first wedge 42 are all connected to the same side. The third wedge 44 fits.

[0064] Also includes a cleaning mechanism 5, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com