Intelligent film pasting equipment for furniture plates

A technology for laminating equipment and boards, applied in the field of furniture manufacturing and processing, can solve the problems of board scratches, warping, and large stretch, and achieve the effects of improving cleaning efficiency, avoiding curling, and uniform adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

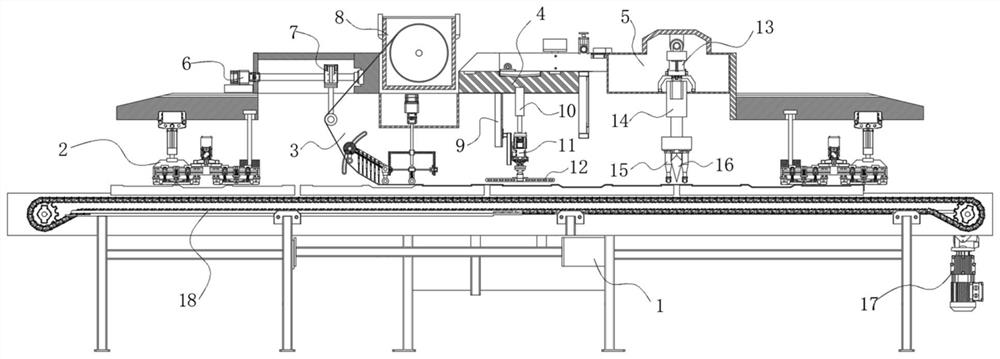

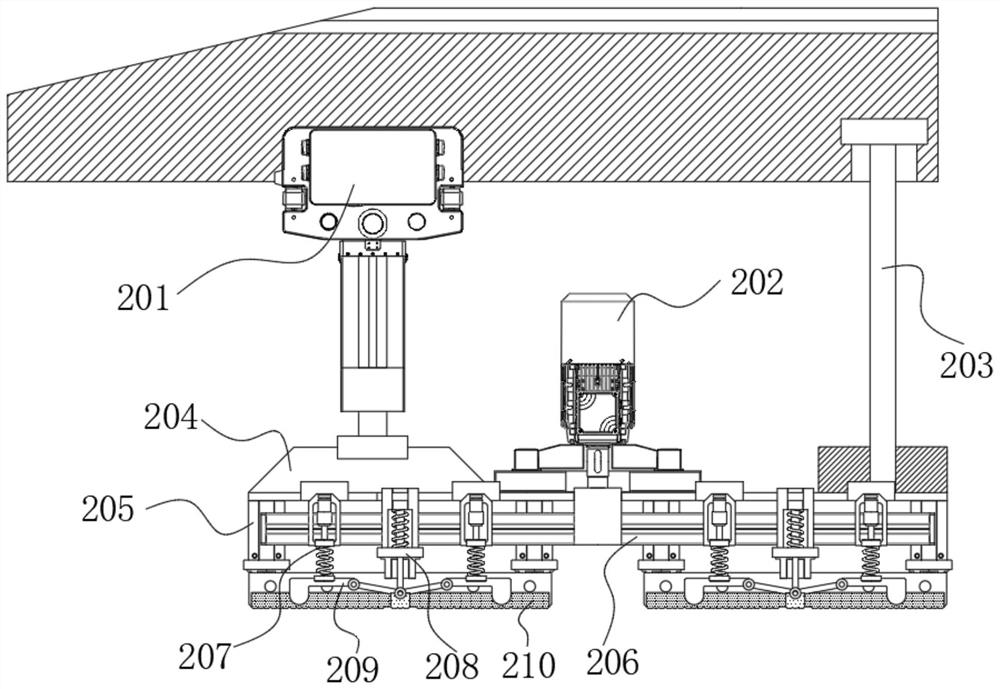

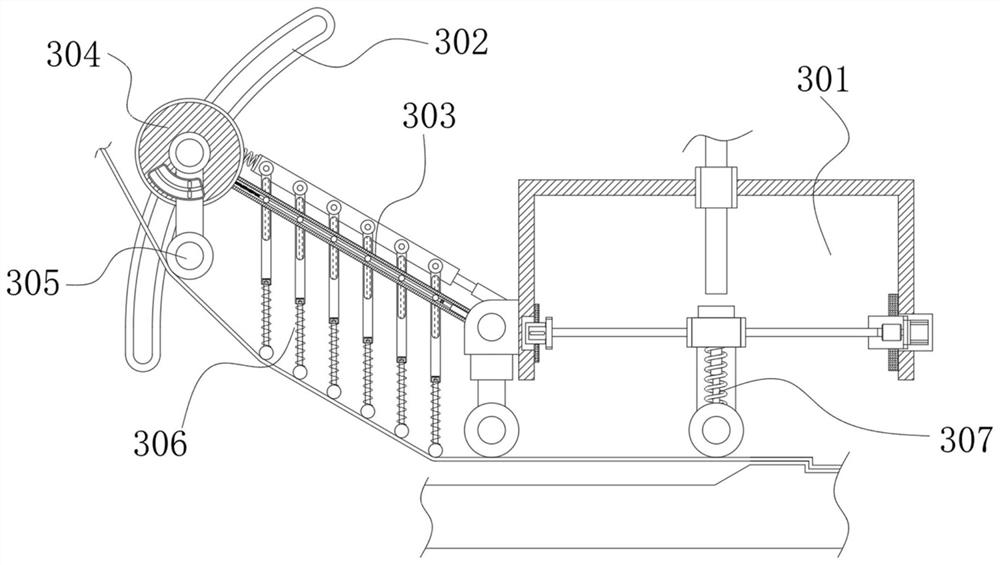

[0026]Referfigure 1 The present invention provides a technical solution: a furniture sheet intelligent film apparatus, including a table 1, a cleaning device 2, a film apparatus 3, a pressure film device 4, a cropping device 5, and a transmission motor 17, the transmission motor 17 drives The conveying chain of the end face on the table 1 18 clockwise, and a device housing is provided above the table 1, the outer casing left, and the lower end face is connected to the right side, and the cleaning device 2 is attached. The device housing between the cleaning apparatus 2 is sequentially mounted from left to right, and a compression film apparatus 4, a crimped device 5 is attached, and a memory box 8 is attached over the film apparatus 3, passed through the cleaning device 2. The surface of the furniture sheet is cleaned, and the surface of the film apparatus 3 is subjected to the surface of the surface of the film, and the cutting device 5 is cut and sealed by the cutting device 5. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap