Automobile roof lining structure

A car roof and inner lining technology, which is applied in the field of car body interior decoration, to achieve the effect of simple composition structure, simple structure and production process, and avoid the problem of appearance wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be described in detail below with reference to the accompanying drawings.

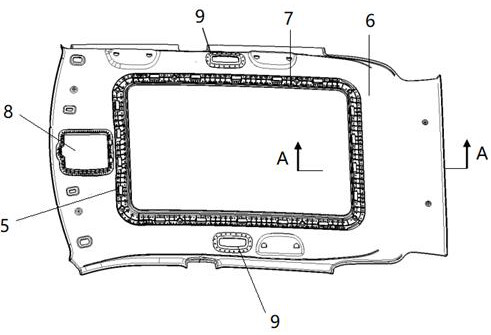

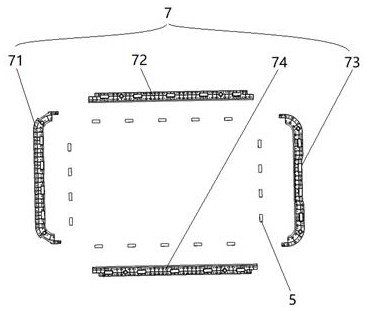

[0036]SeeFigure 5 to 8An automotive top cover is structured, including a top cover liner body 10 and a plurality of mushrooms that are positioned thereon, and the top edge 12 of the top cover is circular 12. The contour shape is adapted to the top cover, and the characteristics are:

[0037]The side headlight frame 16 is provided with a front head frame 14 in front of the top cover liner body 10, and the middle is provided with a skylight frame 15 and two side top lamp frames 16, and two side top lamp frames 16. Located on both sides of the skylight frame;

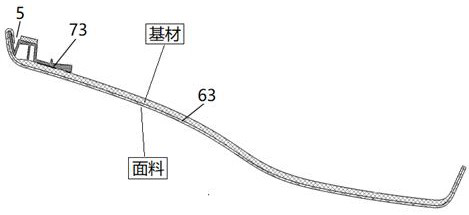

[0038]The top cover liner body 10 is a layered structure, which is composed of a base layer 1, an adhesive layer 2, a sponge sounding layer 3, and a decorative layer 4, and the sponge sounding layer 3 is bonded through the adhesive layer 2. On one side of the base layer 1, the decorative layer 4 is covered on a sponge sounding lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com